Improved rotating ferromagnetic engine

A technology of rotary motion and engine, applied in the direction of generator/motor, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of high-efficiency magnetic motor without reasonable shielding method of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

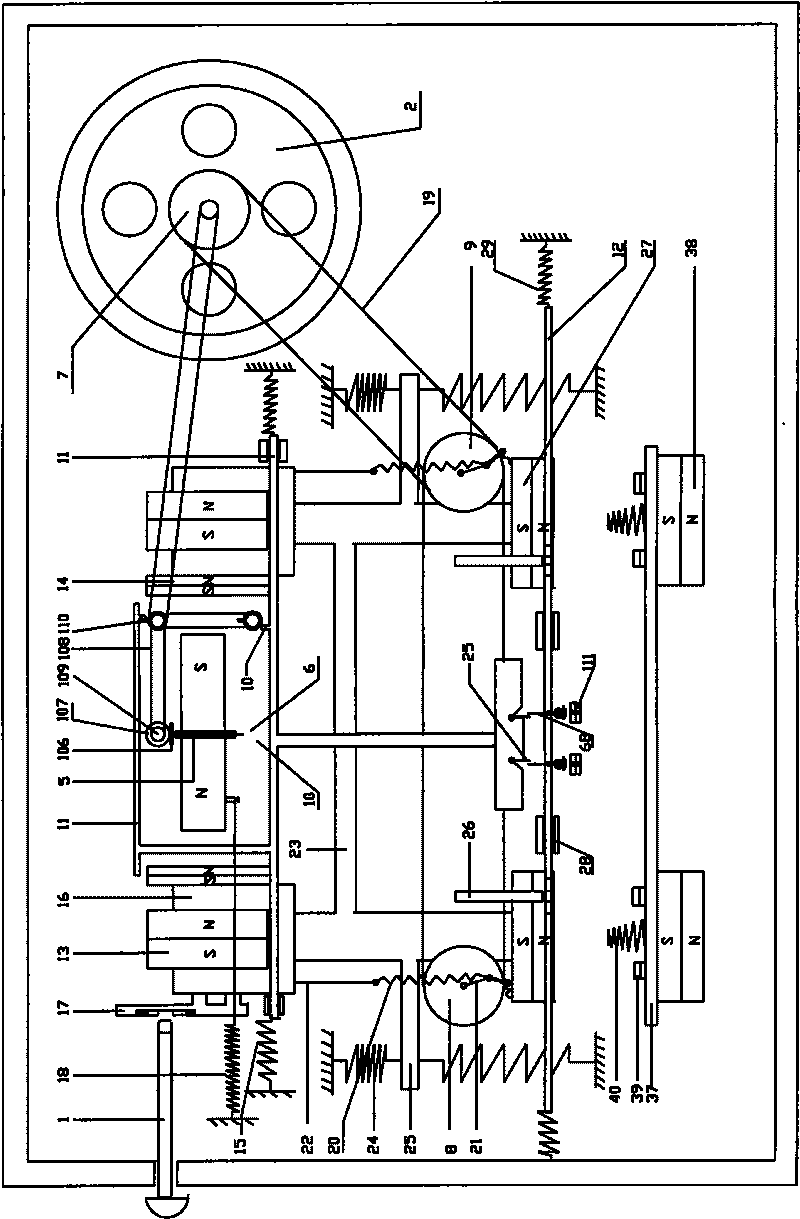

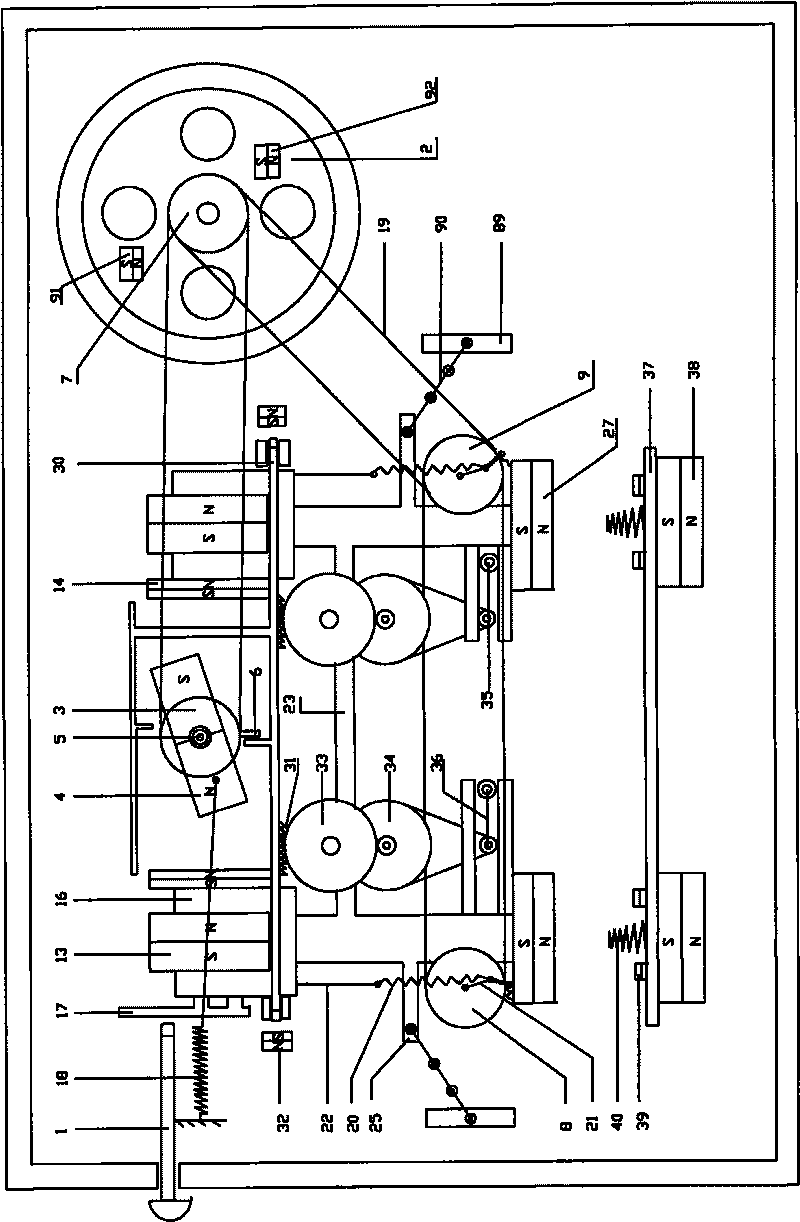

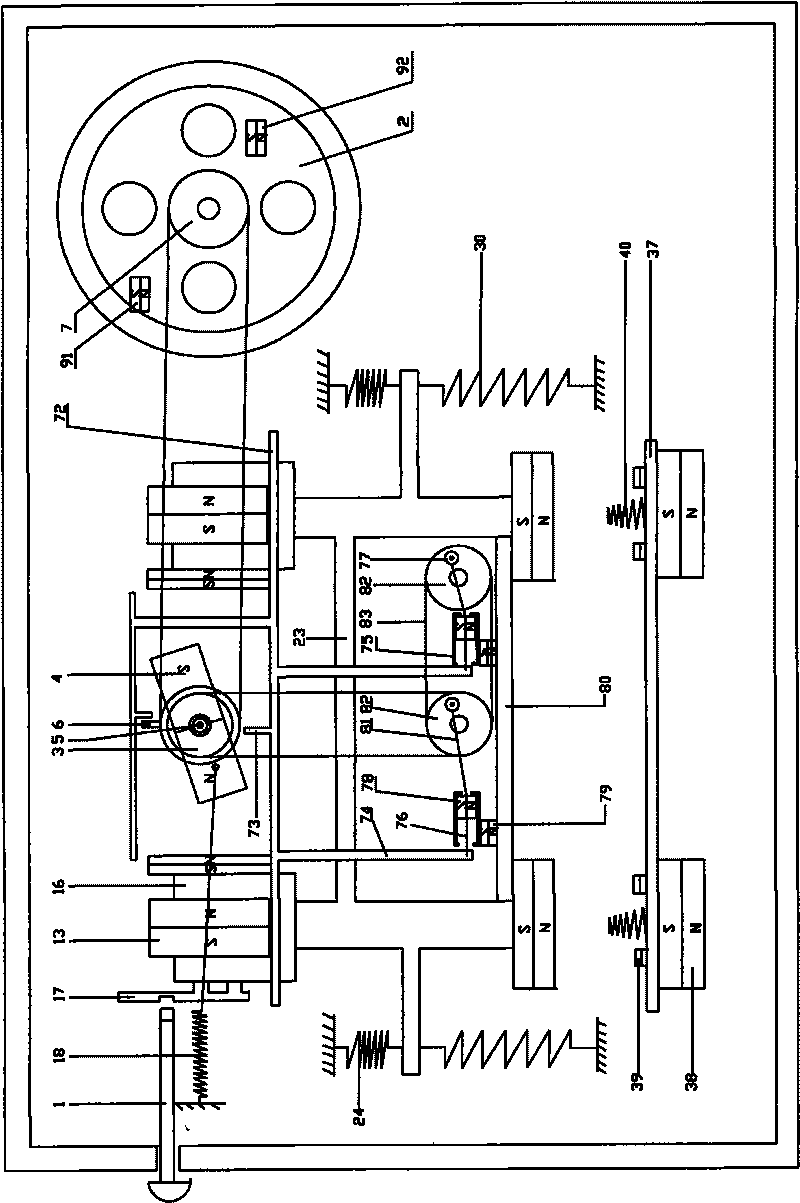

[0051] A ferromagnetic motor with a permanent magnet composite (see figure 1 , figure 2 , image 3 ,picture, Figure 5 , Figure 6 , Figure 7 ), consisting of a casing and an engine built into the casing.

[0052] The housing is provided with a start-stop knob 1, and the engine is composed of a power output system, an operation control system, a reaction force adjustment system, and a vibration reduction system.

[0053] The ferromagnetic motor is stopped by limiting the motion (of the overall motion system). When locking, the head of the start-stop knob should be inserted into the locking hole, and the locking hole can be on the U-shaped shielding block or on its appendage. The structure of the locking hole is that a compressible spring is respectively arranged on both sides of the locking hole on the straight line of its movement. This allows for a quick stop while avoiding shocks and vibrations. As shown in the attached body 17 of the U-shaped shielding block in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com