Method and apparatus for remediation of and recovery from a clutch slip event in a hybrid powertrain system

A clutch and powertrain technology, applied in the field of control systems of electro-mechanical transmissions, can solve problems such as negative effects on handling performance, acceleration changes, and emergency stops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

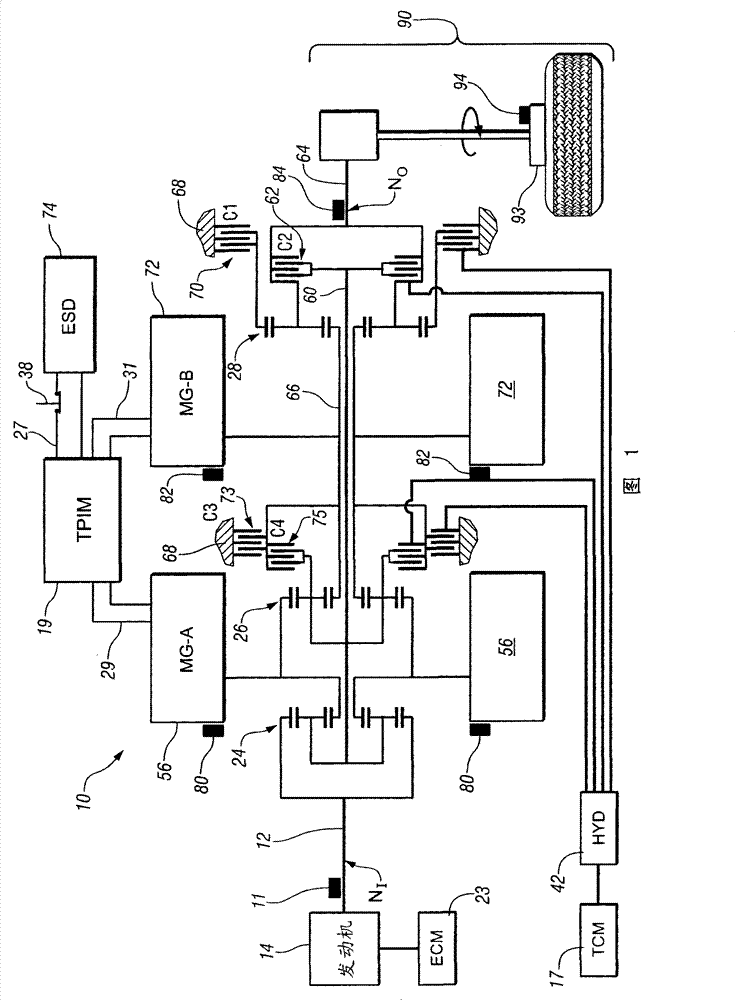

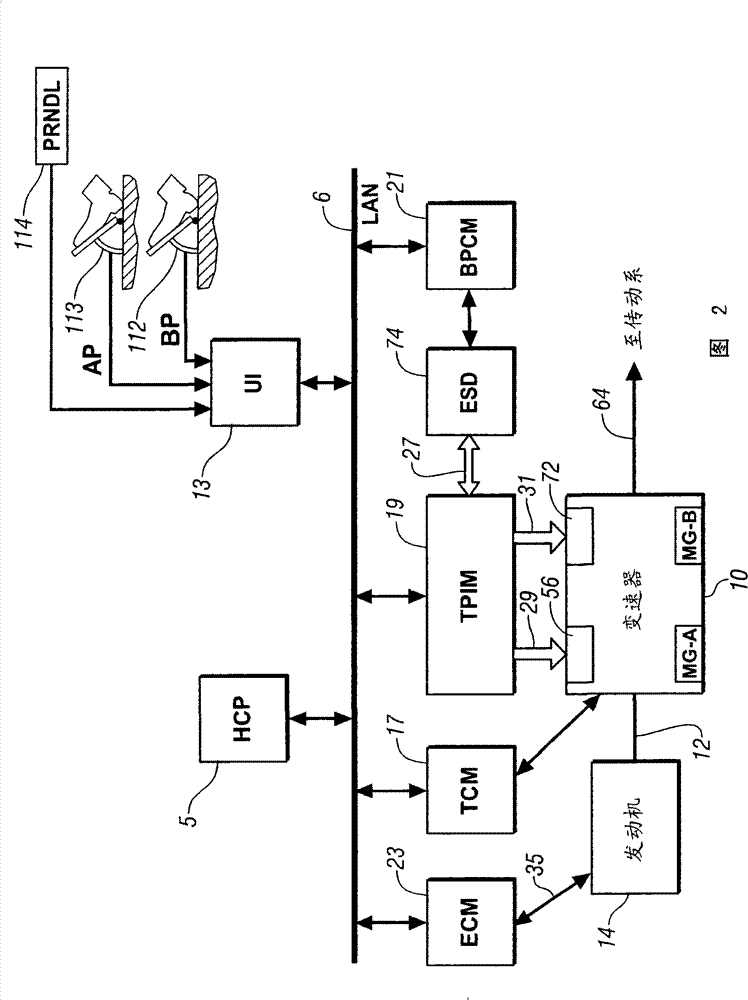

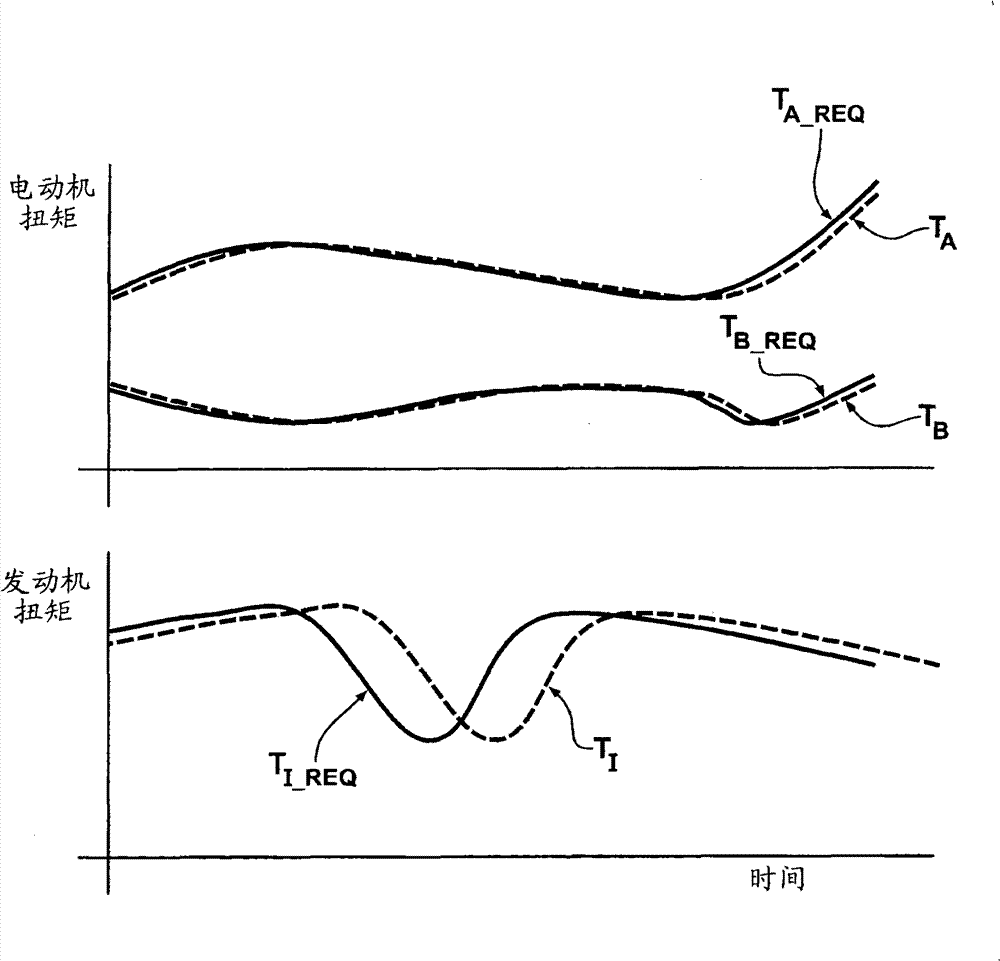

[0017] Referring now to the drawings, which are shown for purposes of illustration of certain exemplary embodiments only and not for purposes of limitation thereof, figure 1 and 2 An exemplary electro-mechanical hybrid powertrain is described. An exemplary electro-mechanical hybrid powertrain based on the present invention is in figure 1 , comprising a dual-mode, compound-split, electro-mechanical hybrid transmission 10 operative with an engine 14 and first and second electric machines ('MG-A') 56 and ('MG-B') 72 connect. The engine 14 and the first and second electric machines 56 and 72 respectively generate power that is transmitted to the transmission 10 . The power generated by the engine 14 and the first and second electric machines 56 and 72 while being transmitted to the transmission 10 is described in terms of input torque and speed, where the input torque is correspondingly represented as T I ,T A and T B , the velocity correspondingly expressed as N I , N A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com