Crispy-rice rice-laying device

A rice cracker spreader and rice machine technology, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of high labor intensity and low production efficiency for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

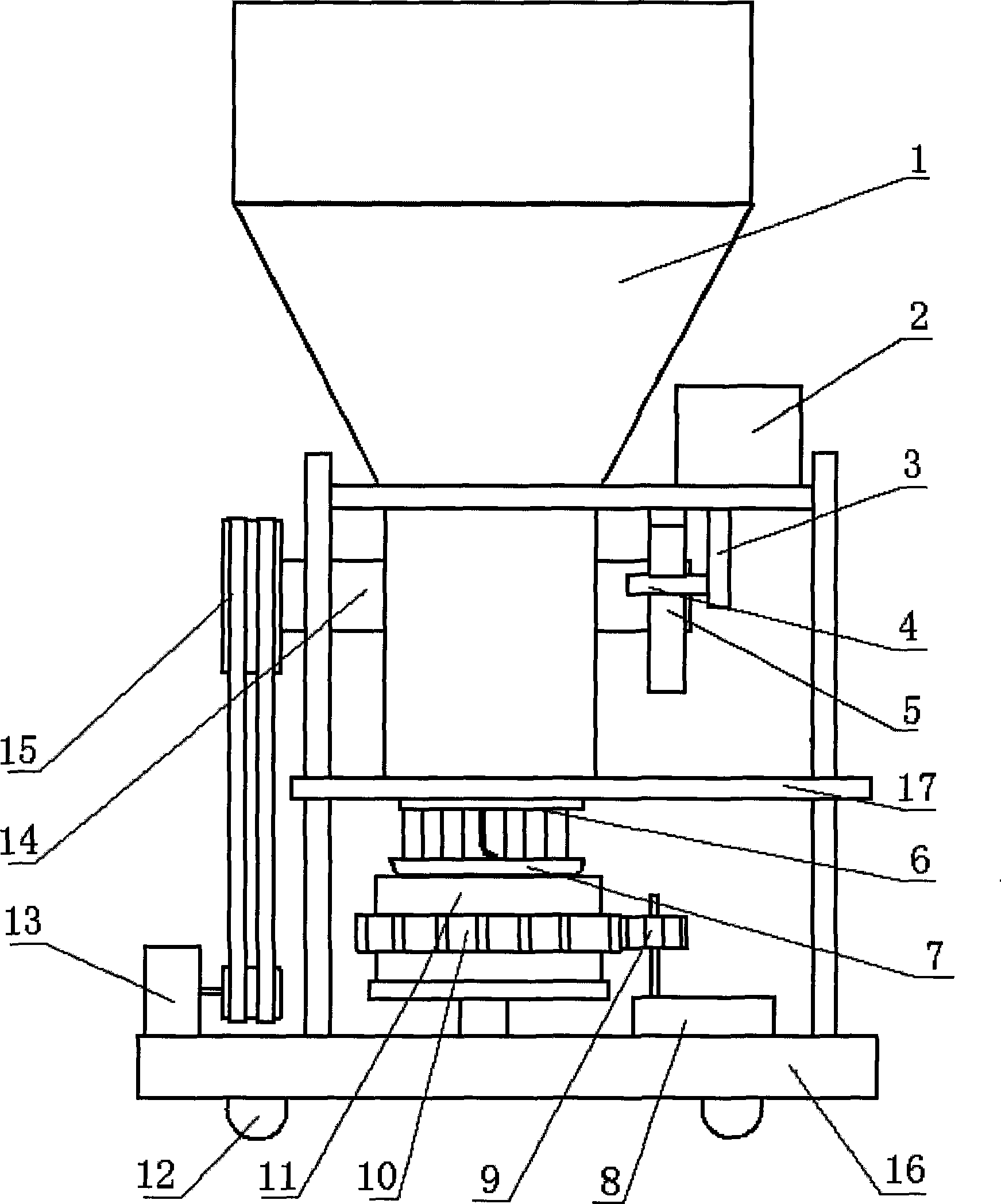

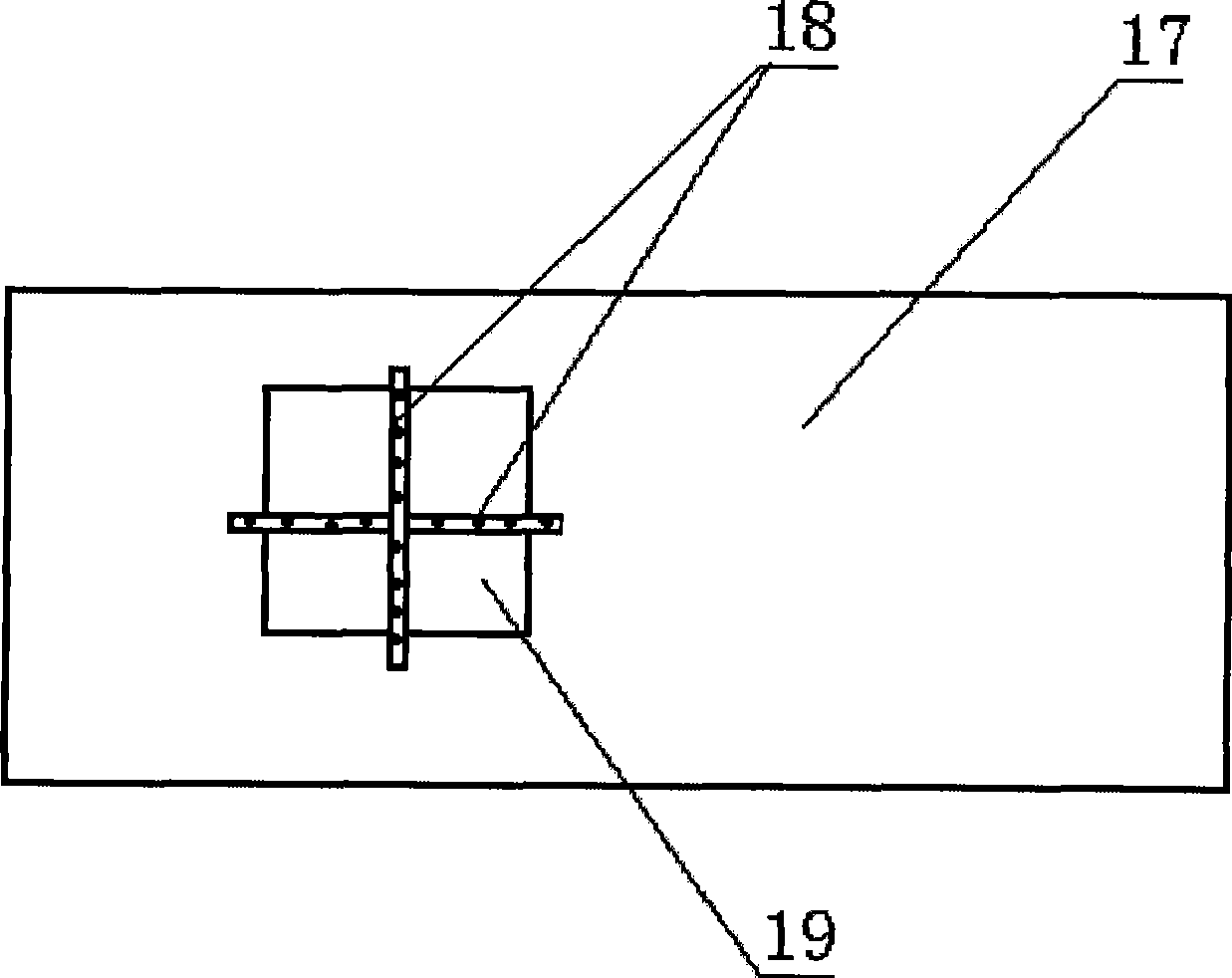

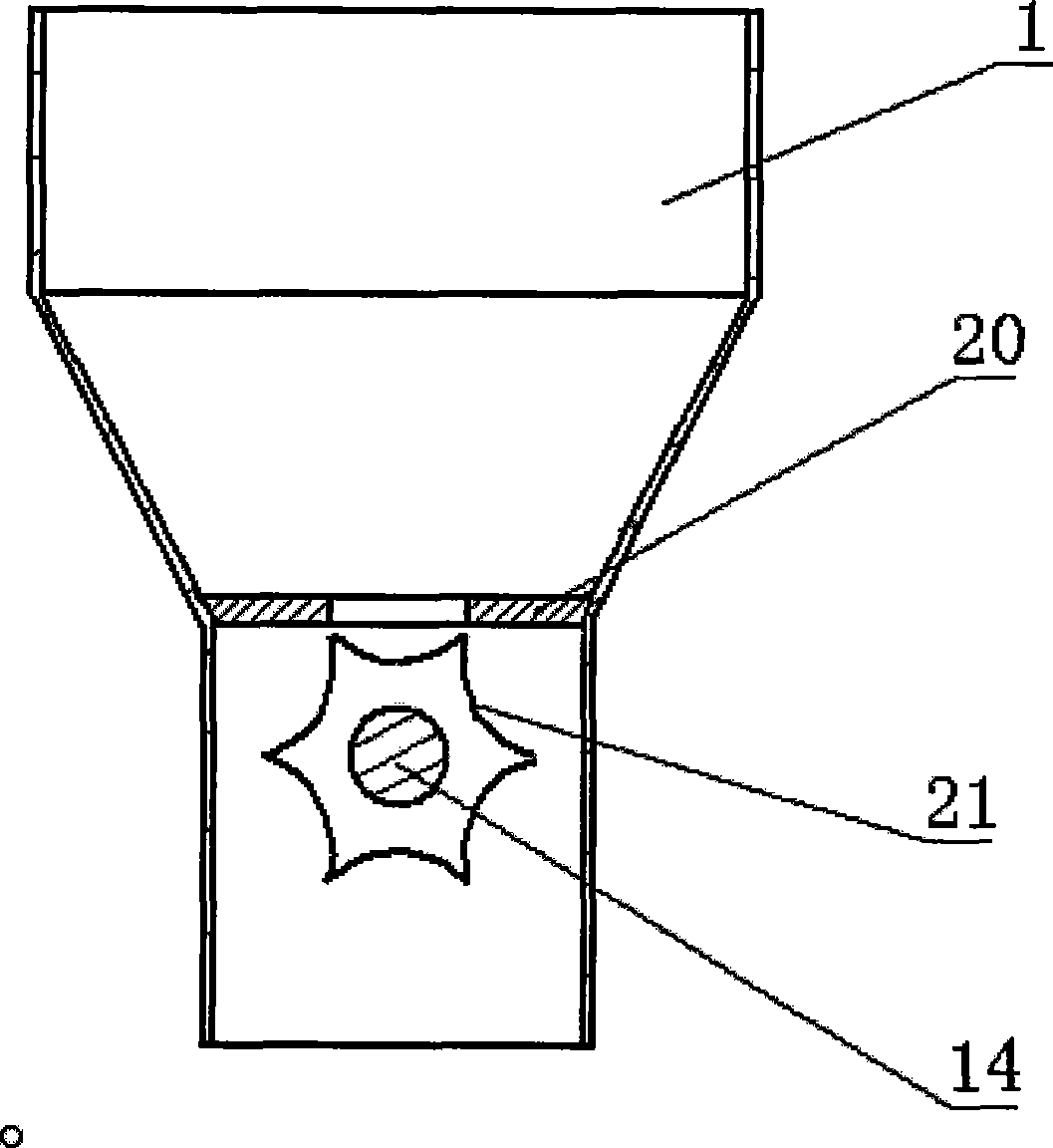

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the crispy rice spreading machine includes a frame 16, a rice hopper mechanism, a drive mechanism and a spreading mechanism, and a roller 12 is installed under the frame 16, and the rice hopper mechanism includes a rice hopper 1, a timing controller 2, a connecting rod 3, Stop roller 4, indexing wheel 5, mandrel 14, dividing plate 20, rotating rice container 21 and belt pulley 15, dividing plate 20 in the rice bucket 1 has an opening, and the opening of dividing plate 20 just below has to rotate and hold rice. Device 21, the rotating rice container 21 is made of stainless steel material, and the rotating rice container 21 has six rice container evenly distributed on concentric circles, the chord length of each container is consistent with the opening width of the dividing plate 20, and the rotating container The interval between the maximum outer circle of the meal container 21 and the dividing plate is 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com