Heating type paste-like material quantitative packing machine

A quantitative dispensing machine and paste technology, which is applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of poor fluidity of paste materials, low packaging accuracy, and limited application range, so as to avoid condensation and Blocking, easy to operate and easy to grasp, and the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

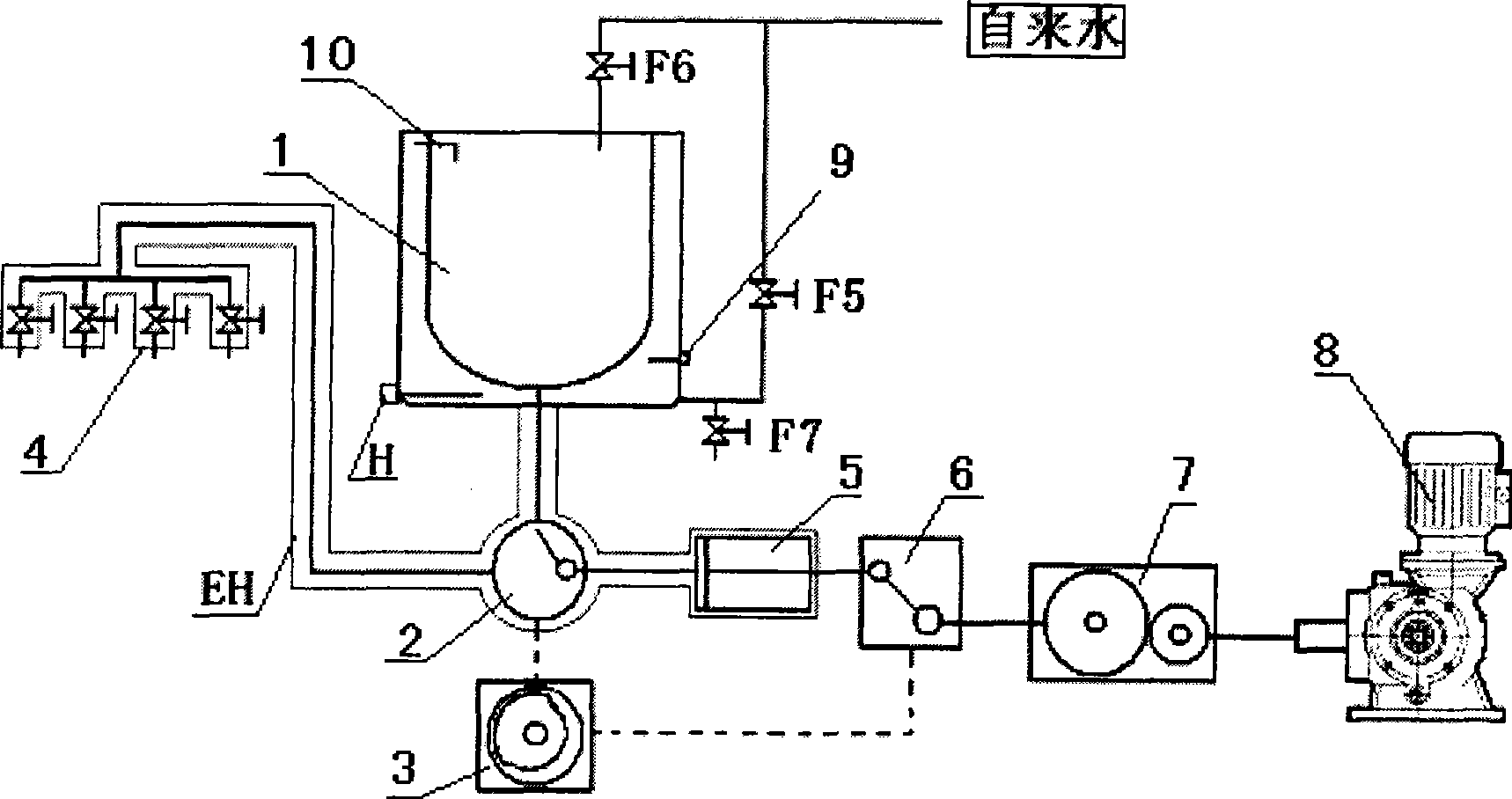

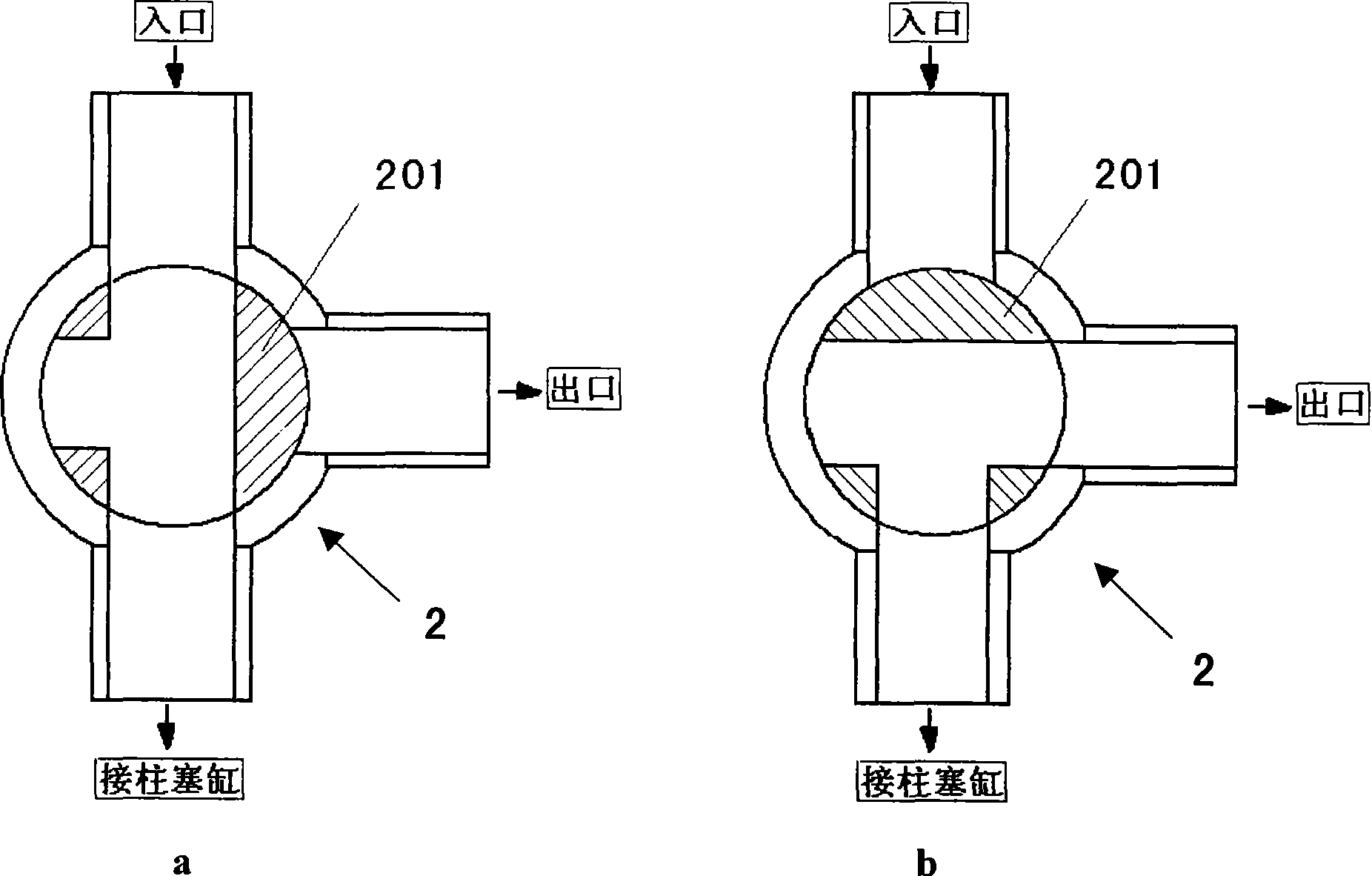

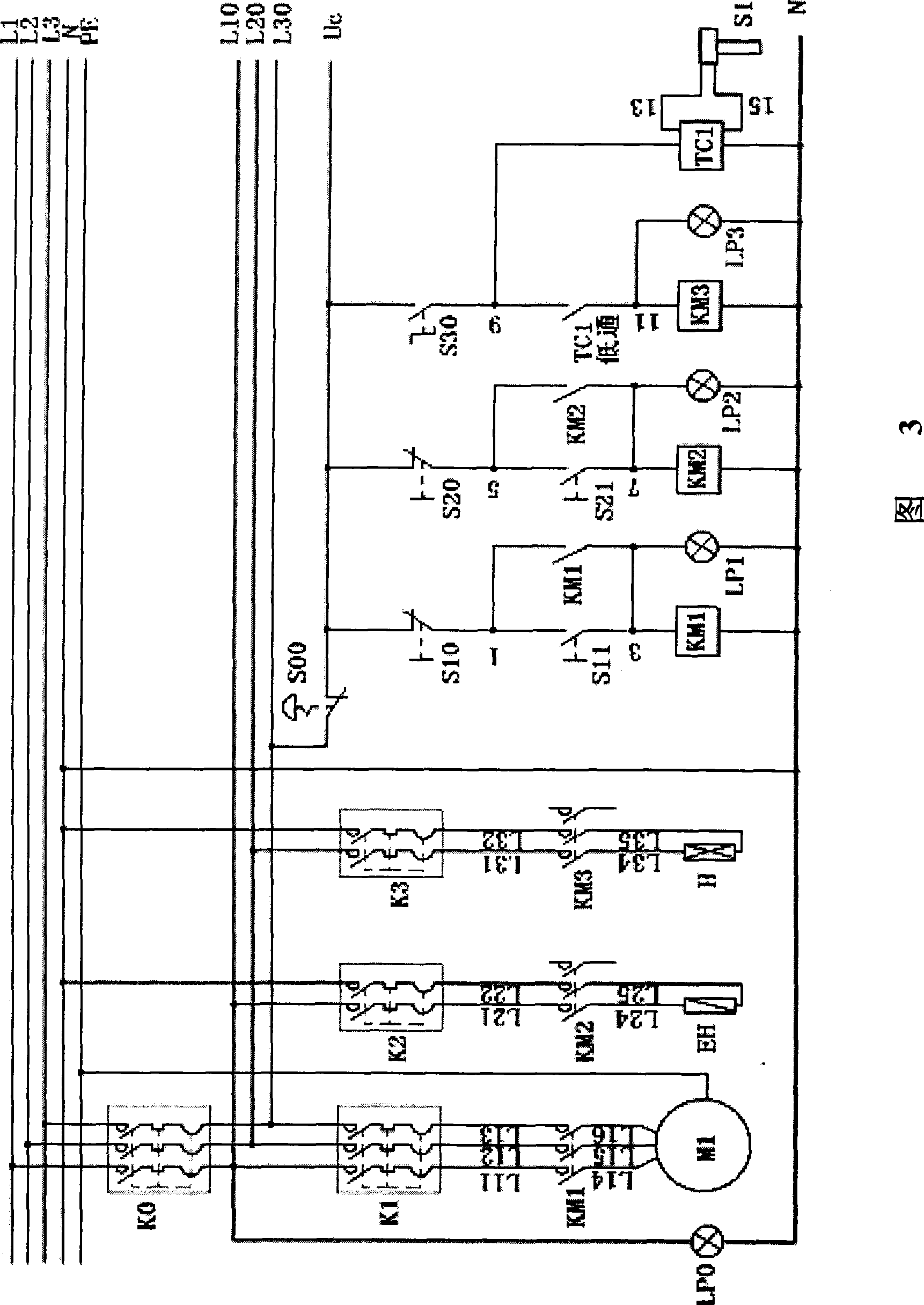

[0027] like figure 1 As shown, the quantitative dispensing machine of heat-tracing type pasty material of the present invention (this embodiment focuses on pasty material) comprises a subpackaging tank body 1 and a group of packing heads 4 with inlet and outlet openings; subpackaging tank body The discharge port is connected to the inlet of the rotary reversing valve 2. The outlet end of the rotary reversing valve 2 leads to the dispensing head; the direction conversion of the rotary reversing valve is controlled by a cam reversing device 3; the plunger cylinder of a plunger / cylinder block assembly unit 5 is connected with the rotary reversing The third port of the valve is connected, and its plunger is driven by a motor-driven deceleration device to reciprocate; an electric heat tracing system H is installed at the bottom of the filling tank 1, and the rotary reversing valve 2 and the plunger cylinder that the discharge flows through 5 points are equipped with electric heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com