Method for removing chromium nitride film on base material surface

A technology for chromium nitride film and substrate surface, which is applied in the field of removing chromium nitride film and can solve the problems of removing chromium nitride film and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Chromium nitride film chemical stripping solution preparation: 20g sodium hydroxide and 63g potassium permanganate were dissolved in 1 liter of deionized water, stirred and mixed evenly to obtain a concentration of potassium permanganate of 0.4mol / L and a concentration of sodium hydroxide of 0.5mol / L alkaline mixed solution A.

[0022] Chromium nitride film chemical stripping method:

[0023] 1. Use vacuum ion plating technology (Shenzhen Zhenheng Industrial Co., Ltd., model ZHC-800) to coat a layer of chromium nitride film on the surface of stainless steel (40mm×80mm×1mm, Dongguan Rongjia Stainless Steel Raw Material Co., Ltd., 304 type), The thickness is 0.3 μm.

[0024] 2. Soak the stainless steel substrate coated with chromium nitride film in alkaline mixed solution A for 15 minutes, take out the substrate, clean it with water, and dry it with hot air.

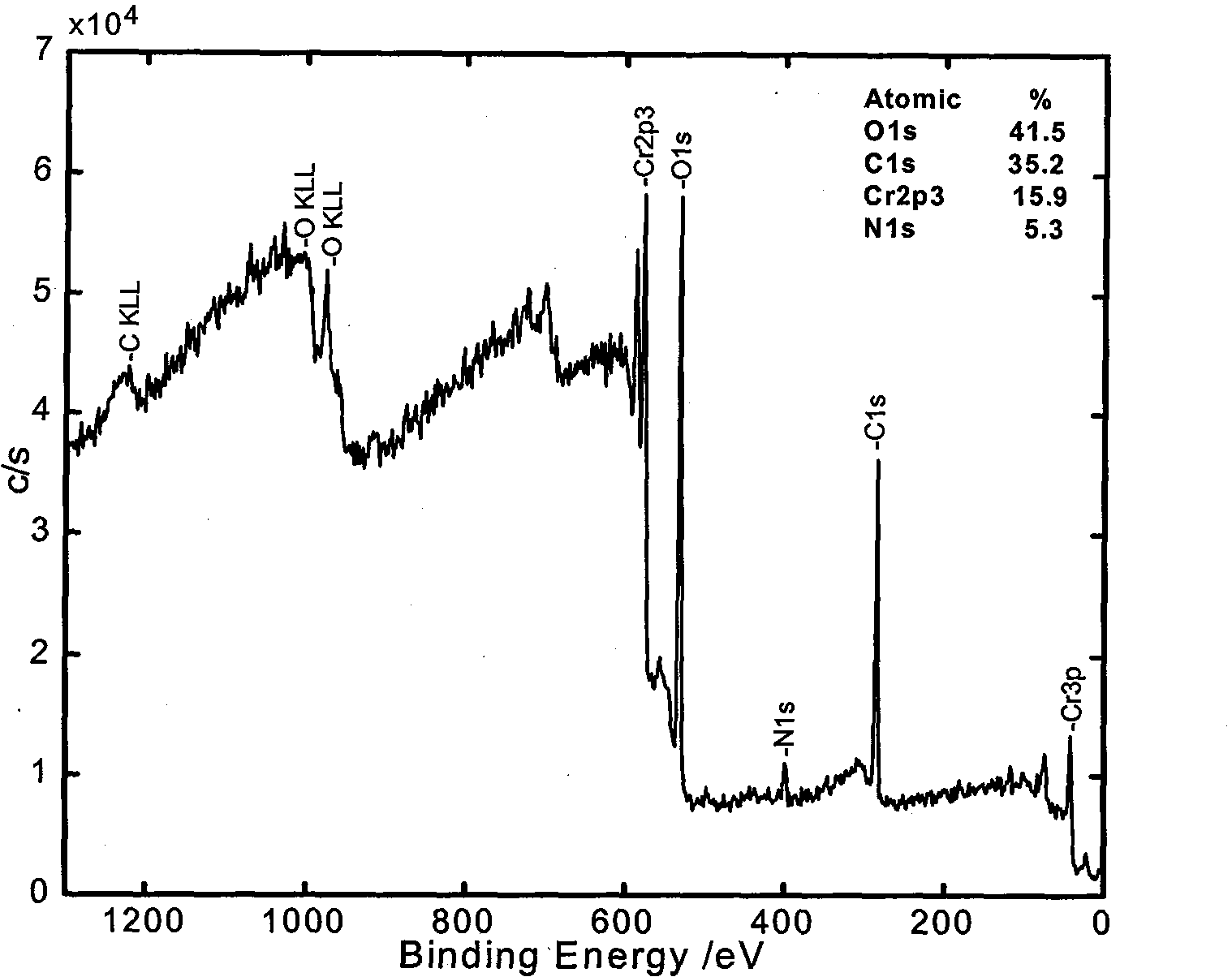

[0025] According to the above operations, the 0.3μm chromium nitride film can be completely removed without cau...

Embodiment 2

[0027] Preparation of chemical stripping solution for chromium nitride film: Dissolve 20g of sodium hydroxide and 32g of potassium permanganate in 1 liter of deionized water, stir and mix evenly to obtain a concentration of potassium permanganate of 0.2mol / L and a concentration of sodium hydroxide 0.5mol / L alkaline mixed solution B; prepare a nitric acid solution with a concentration of 0.008mol / L.

[0028] Chromium nitride film chemical stripping method:

[0029] 1. Utilize the vacuum ion coating technology (same as embodiment 1) to coat one deck of chromium nitride film on the surface of stainless steel (same as embodiment 1), with a thickness of 0.8 μm.

[0030] 2. Soak the stainless steel substrate coated with chromium nitride film in alkaline mixed solution B for 30 minutes, take out the substrate, rinse it with water, and dry it with hot air.

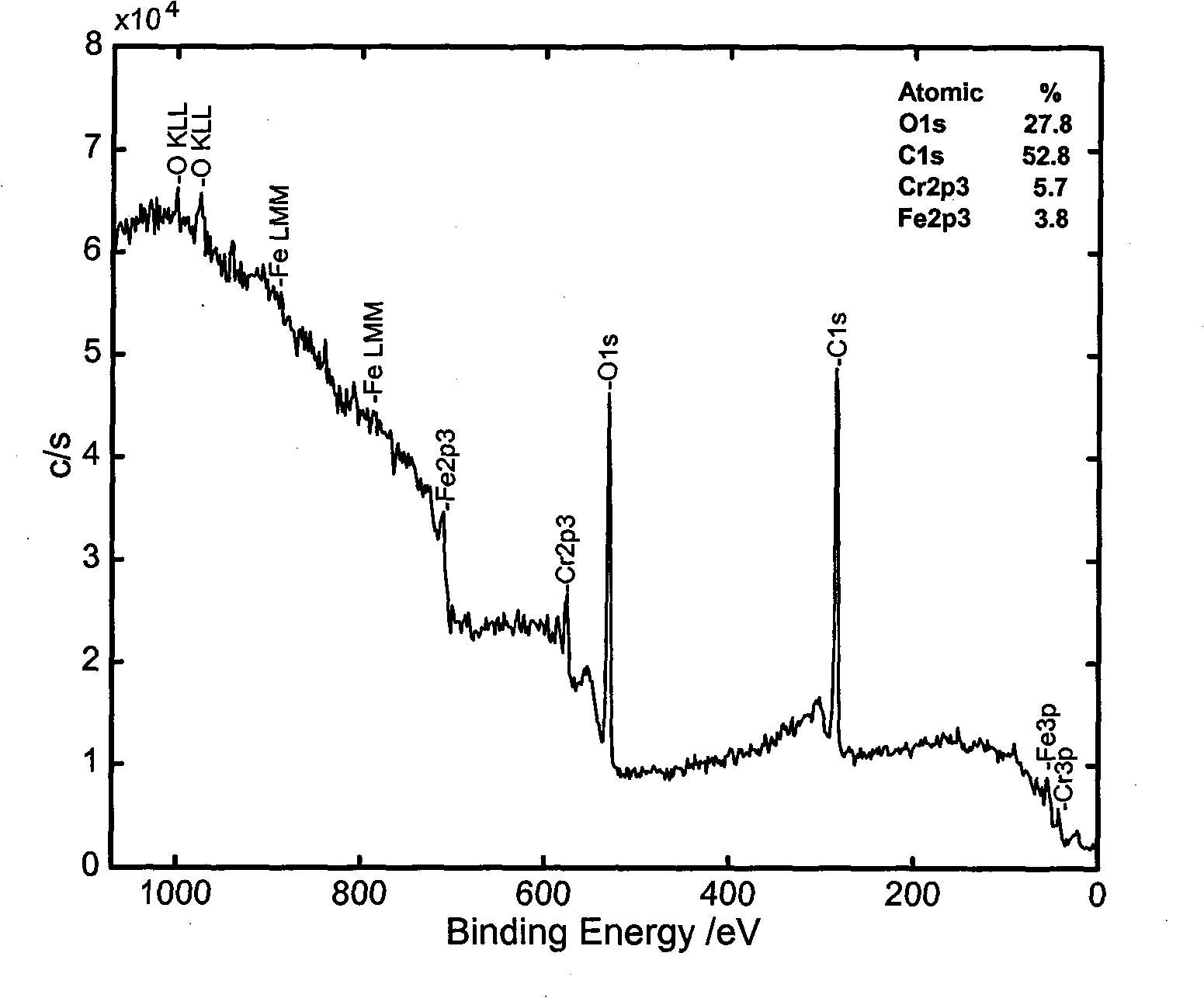

[0031] 3. Transfer the above base material into the above hydrochloric acid solution and soak for 15 seconds. After removing th...

Embodiment 3

[0035] Preparation of chromium nitride film chemical stripping solution: Dissolve 8g of sodium hydroxide and 95g of potassium permanganate in 1 liter of deionized water, stir and mix evenly to obtain a concentration of potassium permanganate of 0.6mol / L and a concentration of sodium hydroxide 0.2mol / L alkaline mixed solution C; prepare a sulfuric acid solution with a concentration of 0.5mol / L.

[0036] Chromium nitride film chemical stripping method:

[0037] 1. Utilize the vacuum ion plating film technology (same as embodiment 1) to coat one deck of chromium nitride film on the surface of stainless steel (same as embodiment 1), with a thickness of 3 μm.

[0038] 2. Soak the stainless steel substrate coated with chromium nitride film in the alkaline mixed solution C for 10 minutes, take out the substrate, rinse it with water, and dry it with hot air.

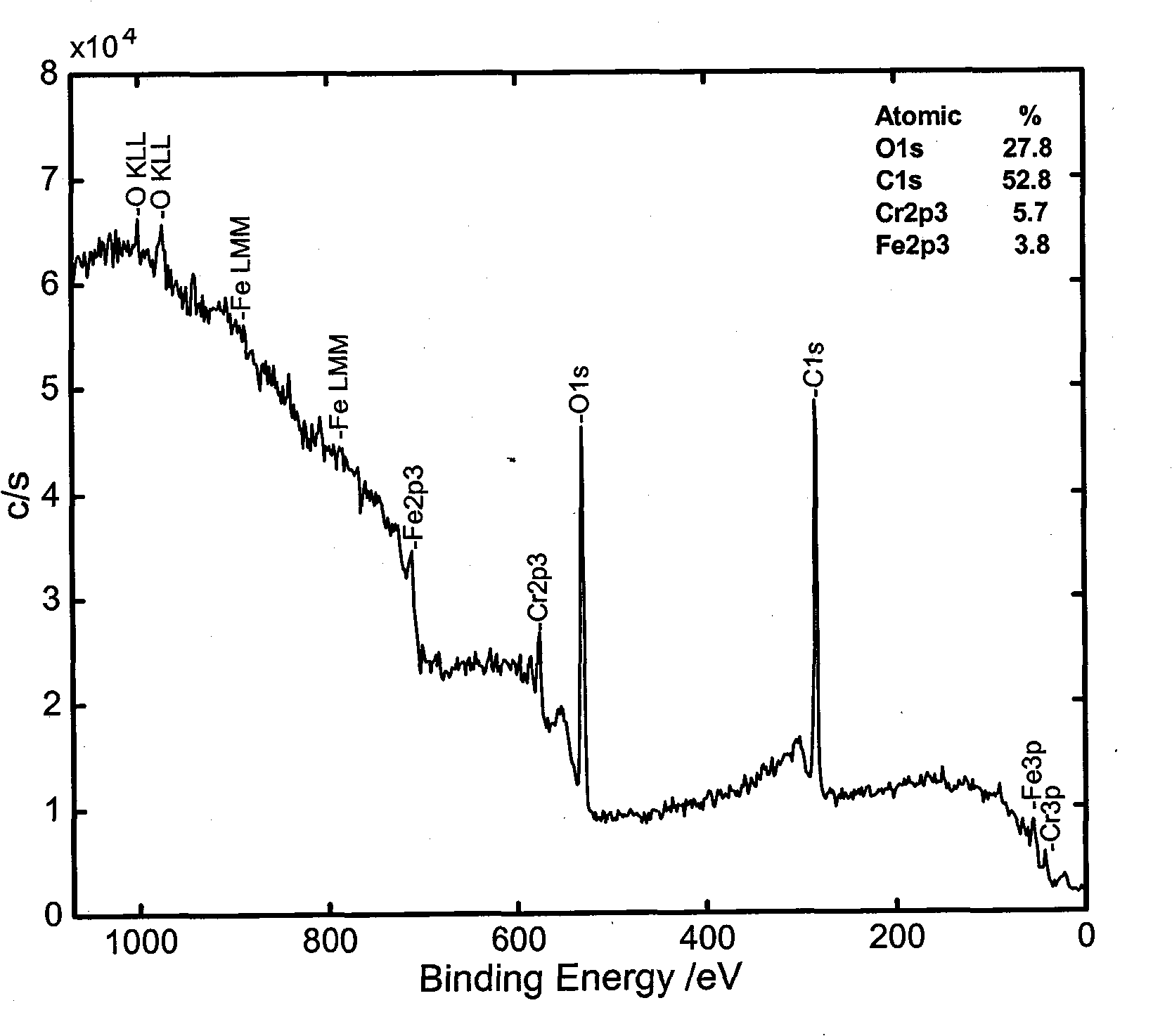

[0039] 3. Transfer the above substrate into the above sulfuric acid and soak for 20 seconds, remove the light yellow precipit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com