Liquid cooling LED lamp

A technology for LED lamps and liquid cooling, which can be used in lampshades, cooling/heating devices of lighting devices, semiconductor/solid-state device components, etc., which can solve problems such as increasing the difficulty of product design and installation, limited space for LED lamps, and multiple interior spaces. , to achieve good heat dissipation effect, improve heat dissipation effect, and make the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

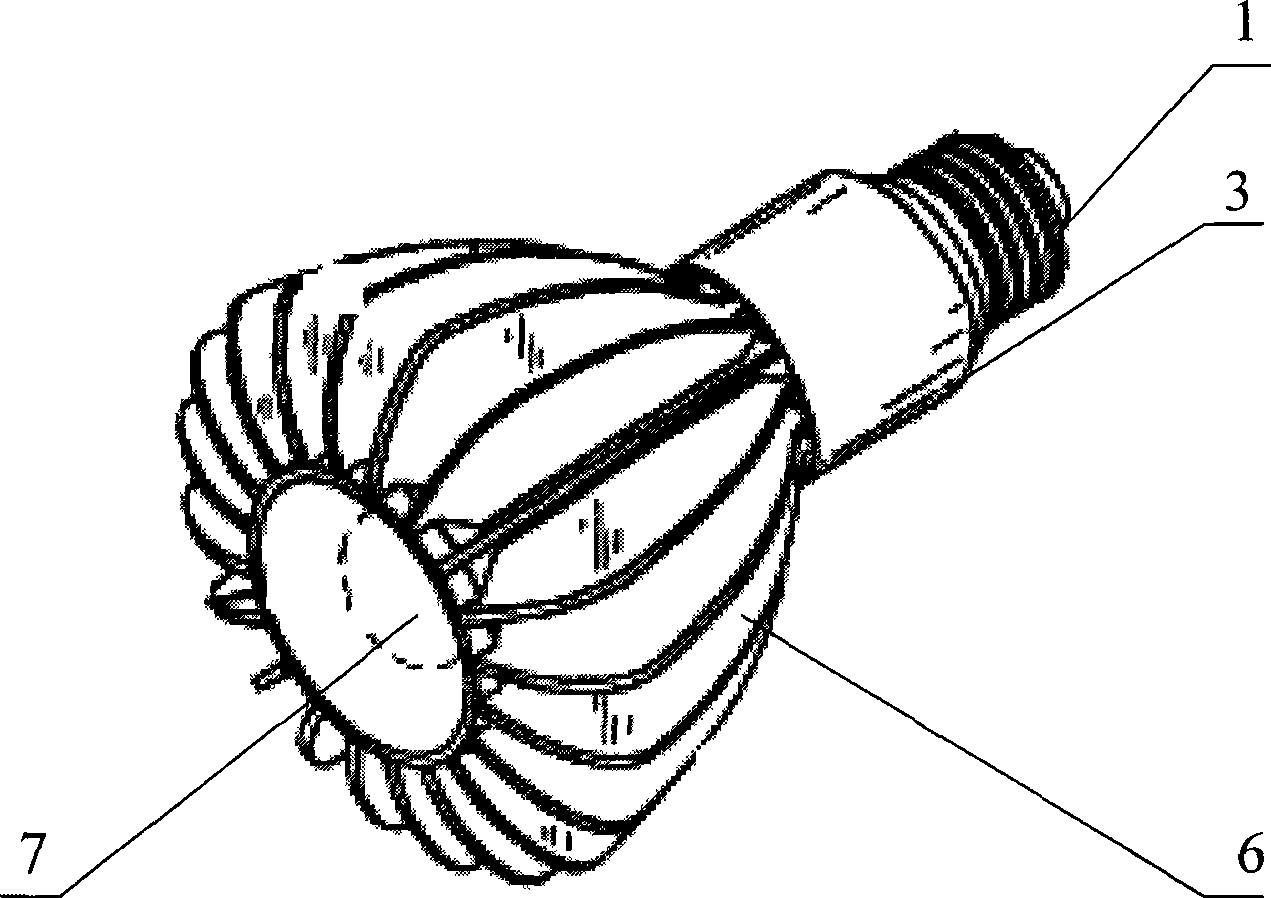

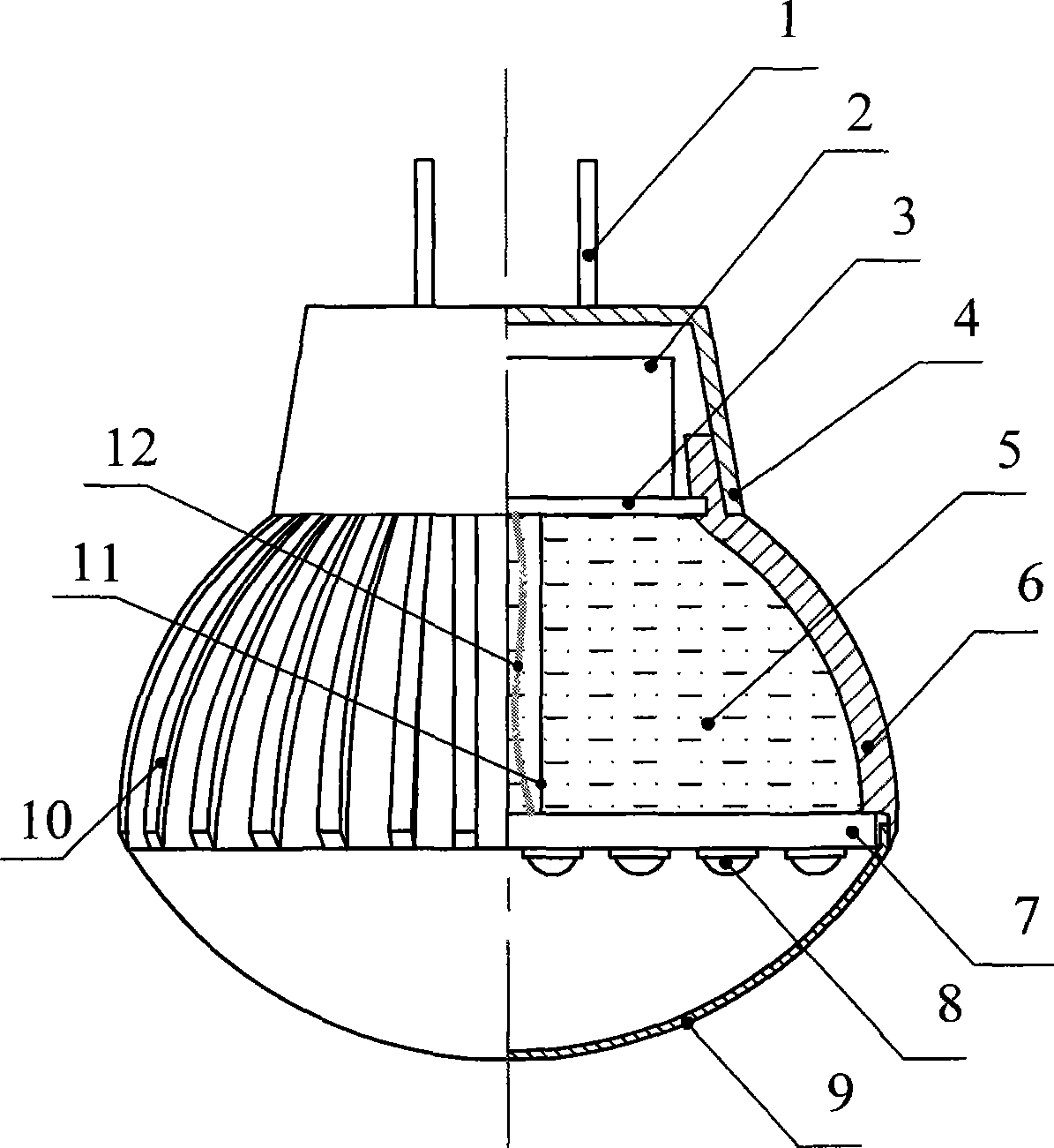

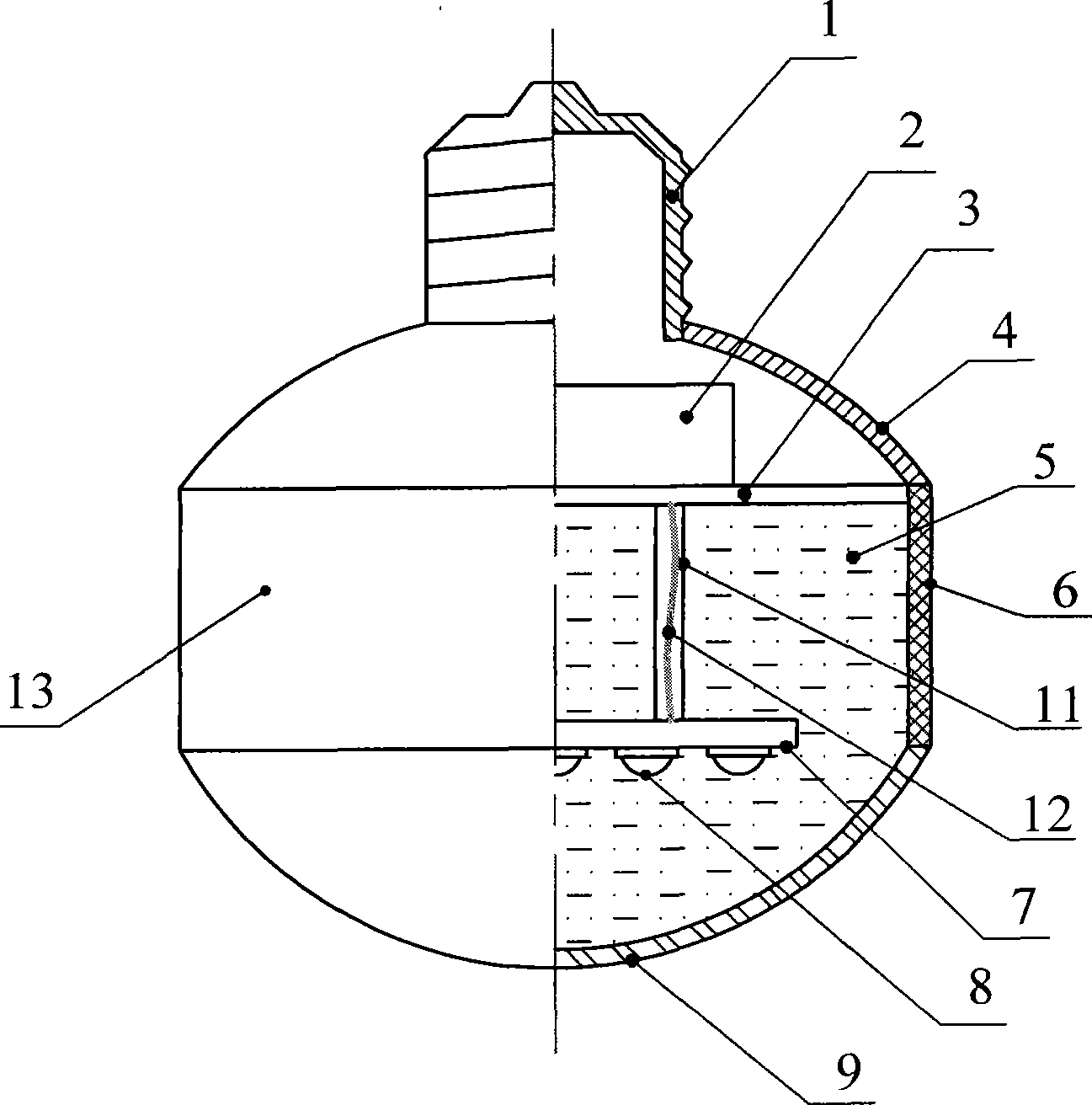

[0029] Such as figure 2 As shown, it is the first embodiment of the present invention. The embodiment of the present invention provides a liquid-cooled LED lighting lamp, including a plug-in electrical connector 1, an LED power supply 2, a lamp holder 4, a heat dissipation lampshade 6, and an aluminum substrate 7 , LED 8, astigmatism lampshade 9. The electrical connector 1 is set on the lower part of the LED lamp cap to connect to the mains, and it is connected to the input of the LED power supply 2. The heat dissipation lampshade 6 is equipped with a high-performance heat-conducting liquid, and the LED power supply 2 is arranged on the heat dissipation lampshade. In the space formed by the upper lamp holder 4 of the partition plate 3 of 6, the LED 8 is arranged on the LED aluminum substrate 7, the periphery of the LED aluminum substrate 7 is closely connected with the lower end of the heat dissipation lampshade 6, and the LED 8 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com