Core rotor assembly dimension measuring device for turbo-charger

A turbocharger and rotor assembly technology, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of unsuitable automatic assembly operations, high labor intensity of workers, and low measurement accuracy, so as to achieve easy query, strong versatility, and high measurement accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

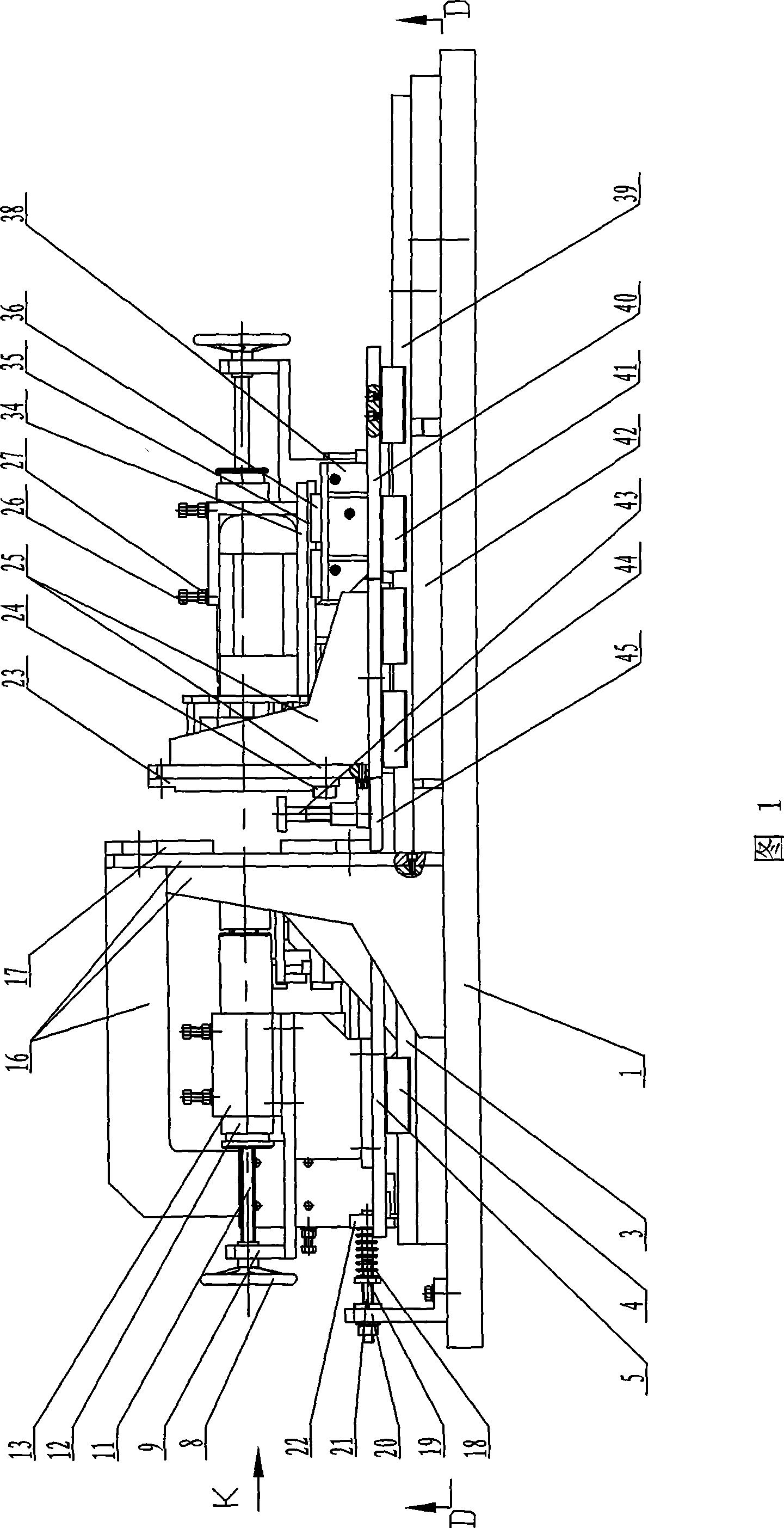

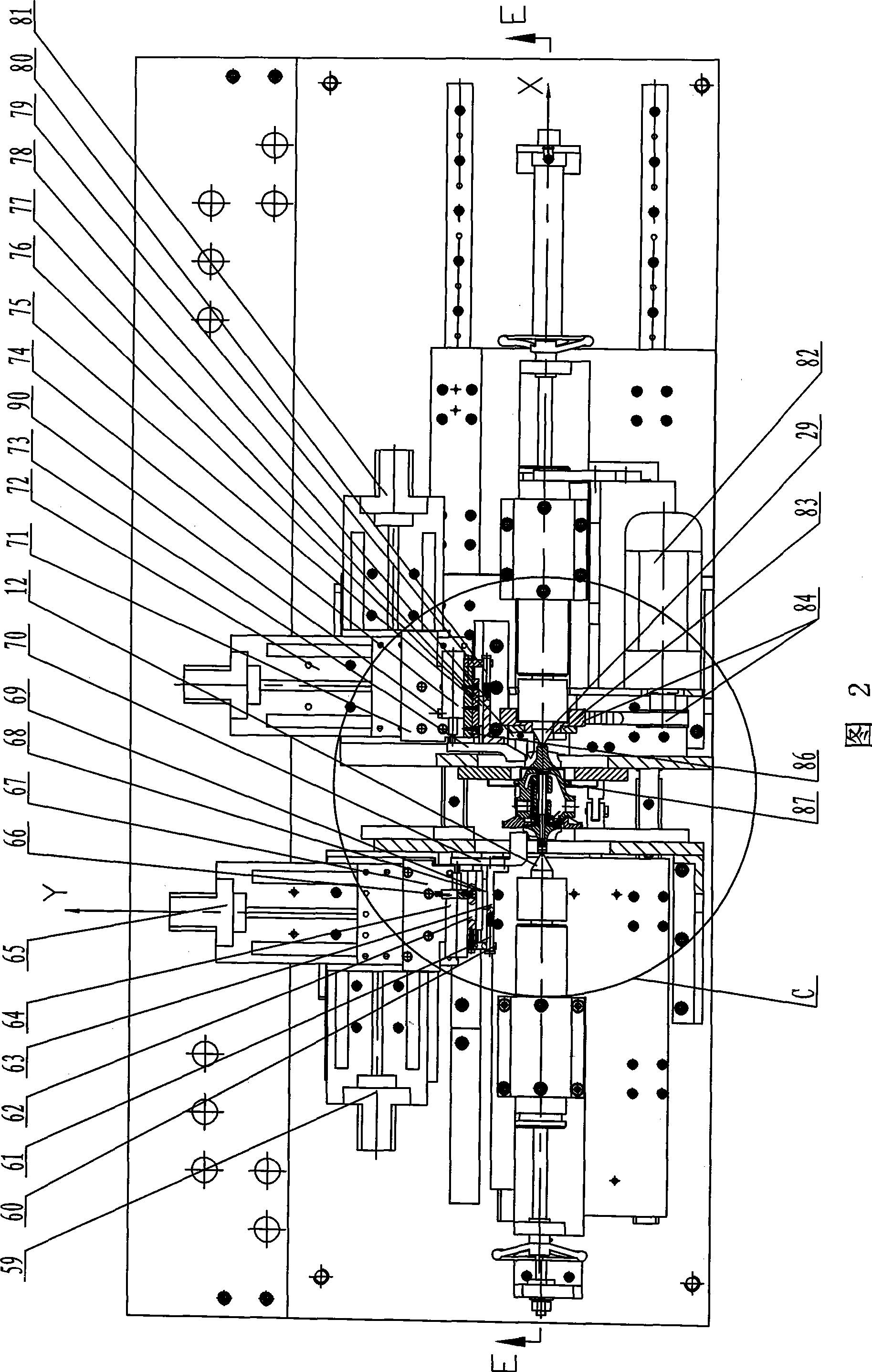

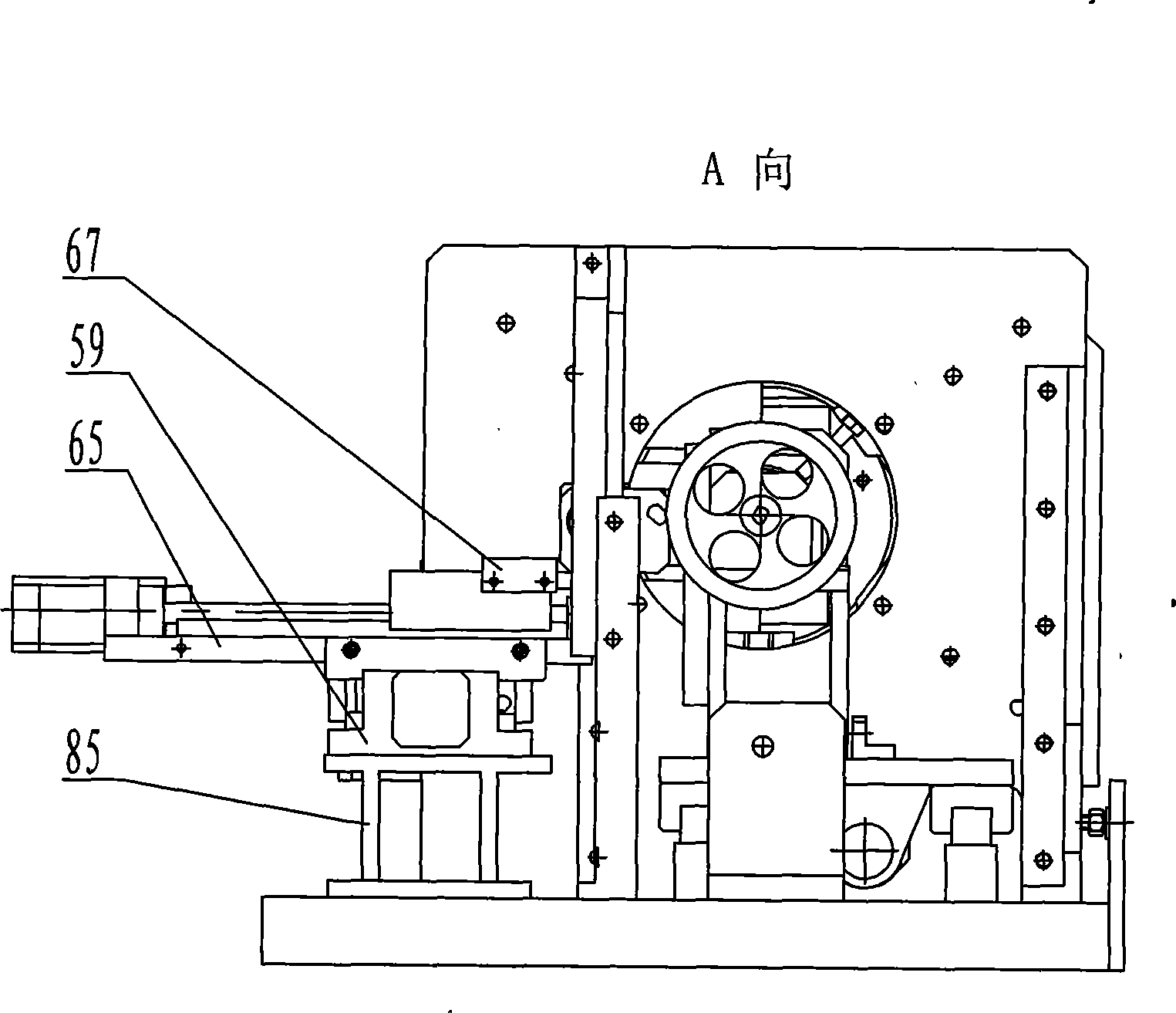

[0007] Specific implementation mode one: in combination with Fig. 1 to Fig. 5 and Figure 8 Describe this embodiment, the measuring device of this embodiment consists of a base 1, an X-to-left linear guide rail 3, an X-to-left slider 4, a left fourth mounting plate 5, a left rotor centering assembly, a left support frame 16, two A left V-shaped positioning block 17, spring 18, adjusting nut 19, screw mandrel left support 20, screw mandrel 21, screw mandrel right support 22, right V-shaped positioning block 23, right guide bar 24, right support frame 25, turn right Sub-centering assembly, motor mounting plate 34, upper linear guide rail 35, upper slider 36, motor support 38, X-right linear guide rail 39, right first mounting plate 40, X-right second slider 41, adjustable Bracket 43, X to the right first slider 44, oil pan 45, right cylinder 47, right second mounting plate 49, positioning head 51, right first bracket 52, left cylinder 54, left guide frame 56, connecting rod 57....

specific Embodiment approach 2

[0008] Specific Embodiment 2: This embodiment is described in conjunction with Fig. 1 and Fig. 5. The left rotor centering assembly of this embodiment consists of a left hand wheel 8, a left bearing seat 9, a left bearing 10, a left lead screw 11, and a left movable top part 12. The left top seat 13, the left lock nut 14 and the left set screw 15 are composed; the left bearing seat 9 is fixedly connected with the left support frame 16, and the inner end of the left lead screw 11 is fixedly connected with the left movable top part 12, The outer end of left screw 11 is fixedly equipped with left hand wheel 8, and left bearing 10 is housed between left bearing block 9 and left screw 11, and left screw 11 and left bearing 10 slide fits, and left top seat 13 is set in the left movable On the top part 12, the left top seat 13 is slidingly matched with the left movable top part 12, the left set screw 15 is mounted on the left top seat 13, and the left lock nut 14 is mounted on the lef...

specific Embodiment approach 3

[0009]Specific Embodiment Three: This embodiment is described in conjunction with Fig. 1 and Fig. 5. The right rotor centering assembly of this embodiment consists of a right set screw 26, a right lock nut 27, a right top seat 28, and a right movable top part 29 , the right lead screw 30, the right bearing seat 31, the right bearing 32 and the right hand wheel 33; The outer end of right leading screw 30 is equipped with right hand wheel 33, and right bearing 32 is housed between right bearing seat 31 and right leading screw 30, and right leading screw 30 and right bearing 32 slide fit, and right top seat 28 suits in the right movable On the top part 29, the right top seat 28 is slidably matched with the right movable top part 29, the right set screw 27 is mounted on the right top seat 28, and the right lock nut 27 is mounted on the right set screw 26. With such arrangement, the structure is simple, and the transmission is stable and reliable. This embodiment is used in combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com