Method for manufacturing touch screen

A manufacturing method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as waste, product scrapping, and poor product appearance, so as to reduce the occurrence rate and improve the appearance yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The manufacturing method of the touch screen of the present invention will be further described in detail with reference to the accompanying drawings.

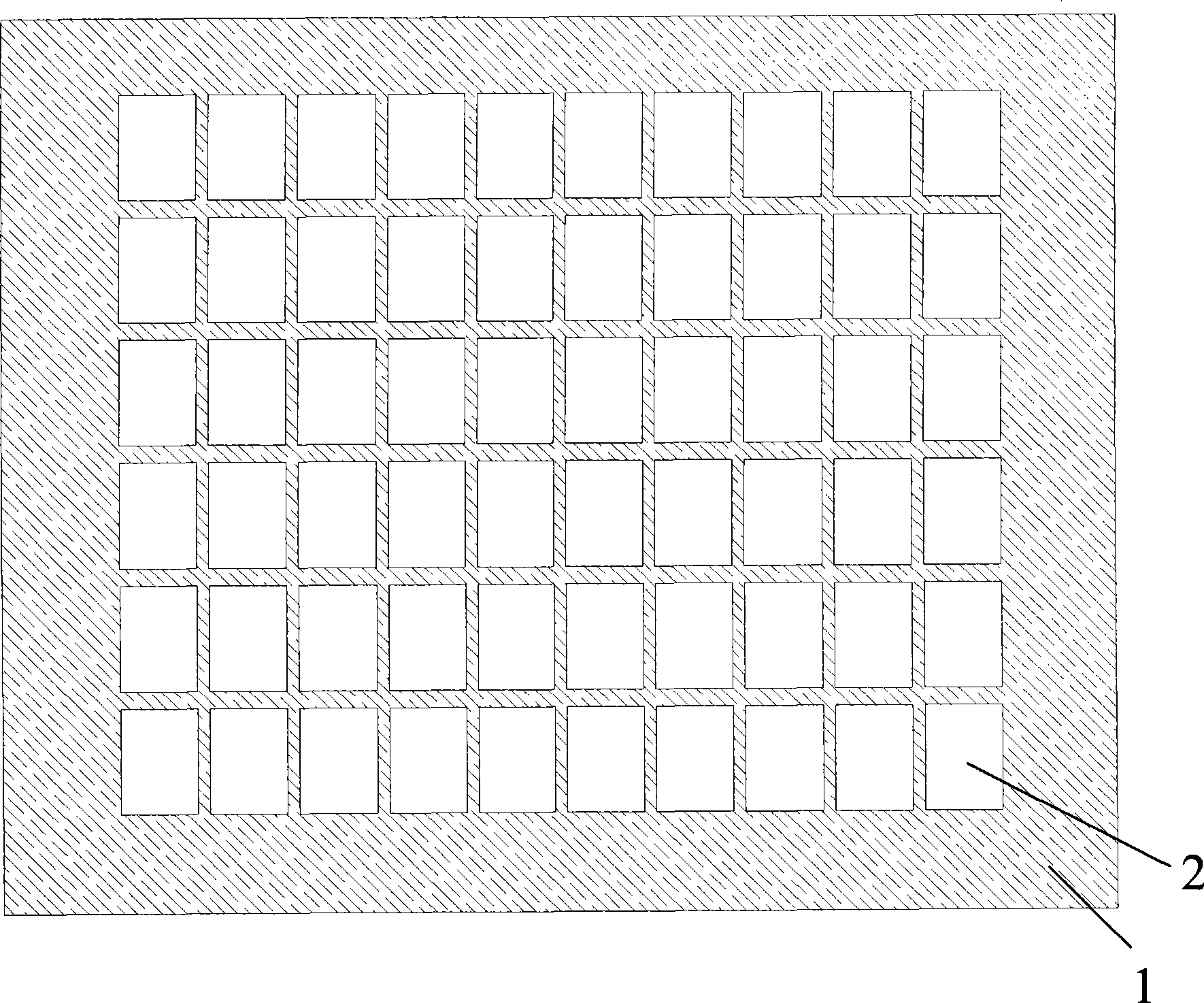

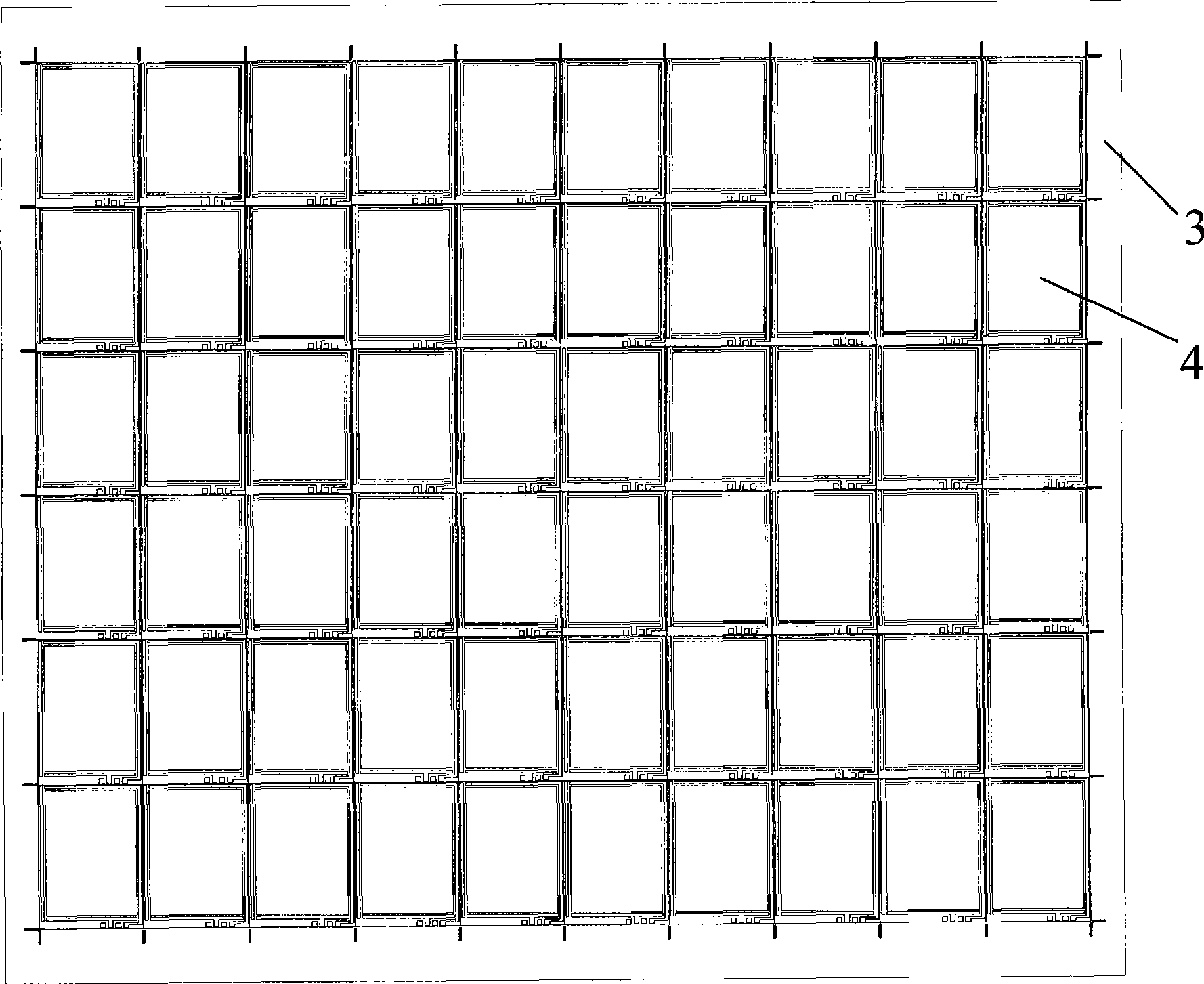

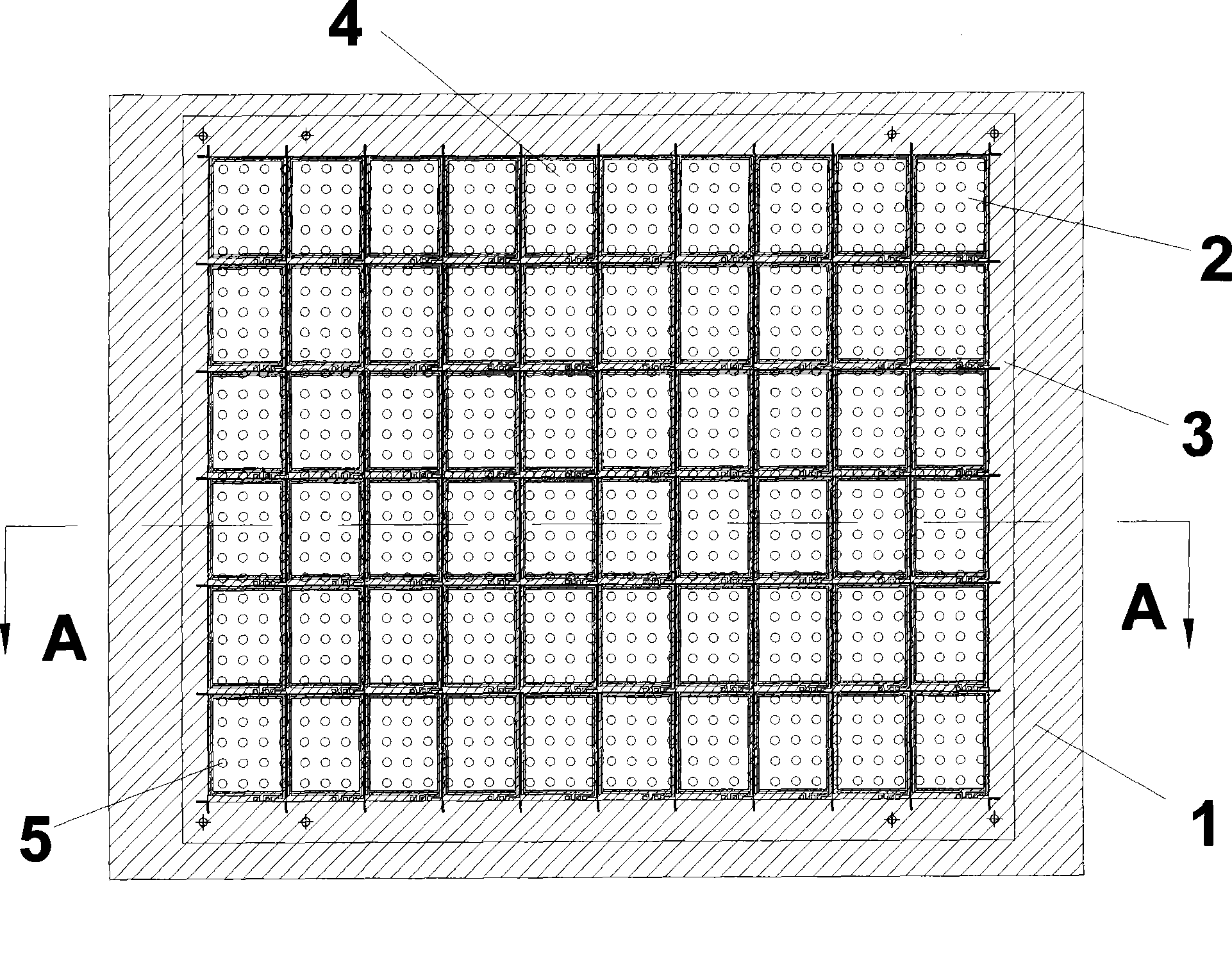

[0014] figure 1 It is a structural schematic diagram of the cutting mat frame of the present invention; as figure 1 As shown, the manufacturing method of the touch screen of the present invention adopts a cutting mat frame 1 with a thickness of 0.075MM, and the material of the cutting mat frame 1 is polyethylene terephthalate (PET). figure 2 It is a structural schematic diagram of the conductive film of the present invention; as figure 2 As shown, a number of action areas 4 are symmetrically arranged on a conductive film 3, and the material of the conductive film 3 is indium tin oxide (Indium Tin Oxide, ITO); wherein, the outer frame size of the cutting mat frame 1 is larger than that of the conductive film 3 The size of the outer frame is to cut out the window pattern 2 corresponding to the size of the action area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com