Method for cleaning wafer surface pollutant particle in CMP process

A contaminant, wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inaccurate display of machine working conditions, too large differences, etc., to achieve moderate speed and selection ratio, use Safe, convenient and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

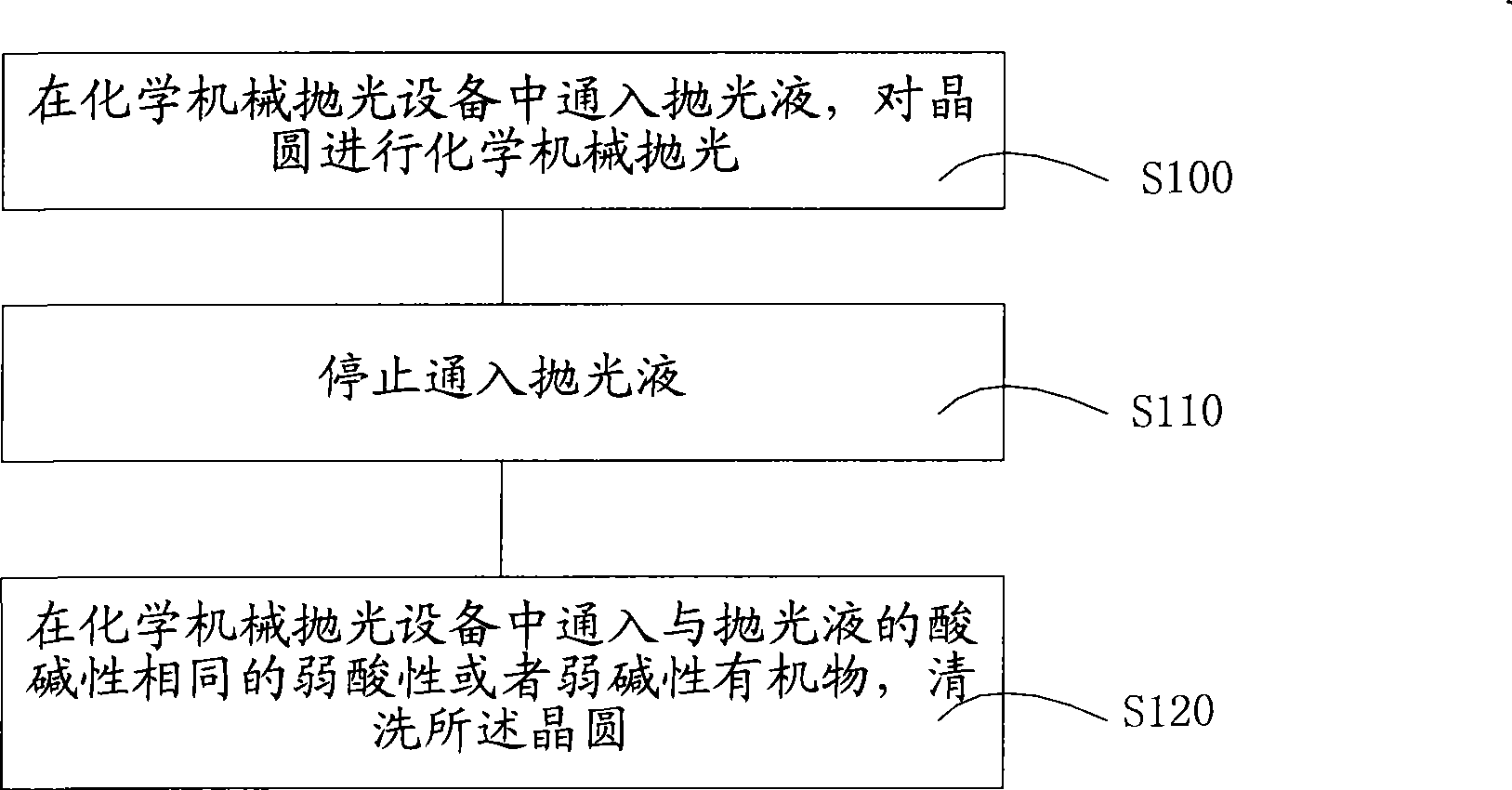

[0026] A method for removing pollutant particles on the wafer surface in a CMP process, referring to the appended figure 1 , including: S100, injecting polishing fluid into the chemical mechanical polishing equipment, and performing chemical mechanical polishing on the wafer; S110, stopping injecting the polishing fluid; S120, injecting the same acidity and alkalinity as the polishing fluid into the chemical mechanical polishing equipment Weakly acidic or weakly alkaline organic matter to clean the wafer.

[0027] The wafer described in this embodiment is a blank semiconductor wafer or a control sheet or a dummy sheet with a film layer on the surface, or a wafer with some film layers or devices formed on the surface during the manufacturing process of the semiconductor device.

[0028] Wherein, the film layers mentioned on the wafer surface refer to all film layers in the manufacturing process of semiconductor devices, such as insulating materials such as silicon oxide and sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com