Internal chemical synthetic reverse charging chemical process for lead acid battery

A lead-acid battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery charging/discharging, etc., can solve the problems of capacity attenuation, unsatisfactory curing effect, etc. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

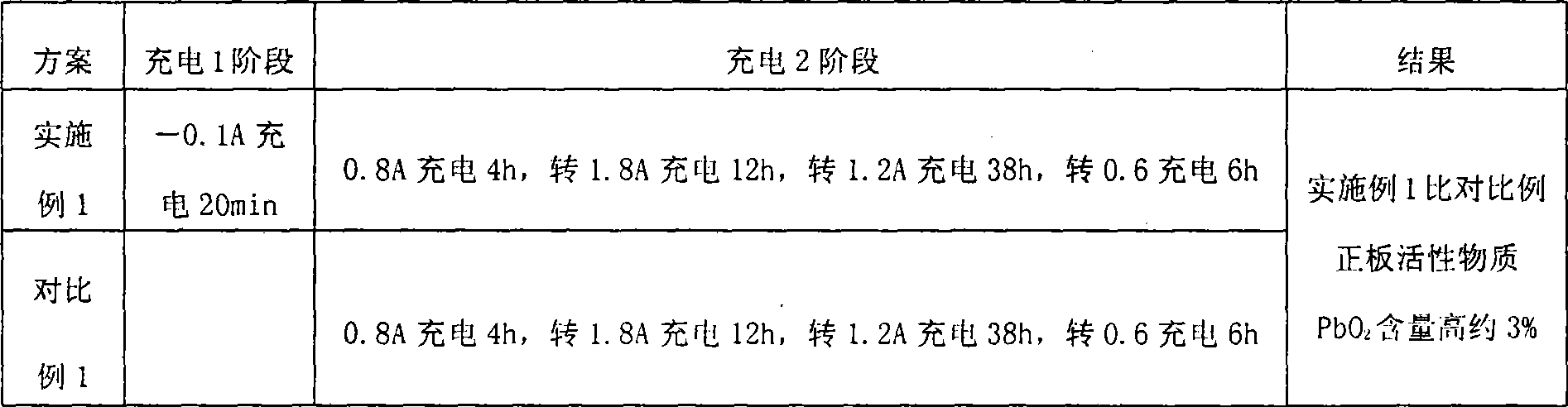

Embodiment 1

[0013] Take a 10Ah battery for an electric bicycle as an example. After the acid filling is completed, the internalization is carried out. The specific internalization steps are as follows: 0.1A reverse charging for 20min, then forward charging, 0.8A charging for 4h, 1.8A charging for 12h, and 1.2A charging Charge for 38 hours, and charge for 6 hours at 0.6A.

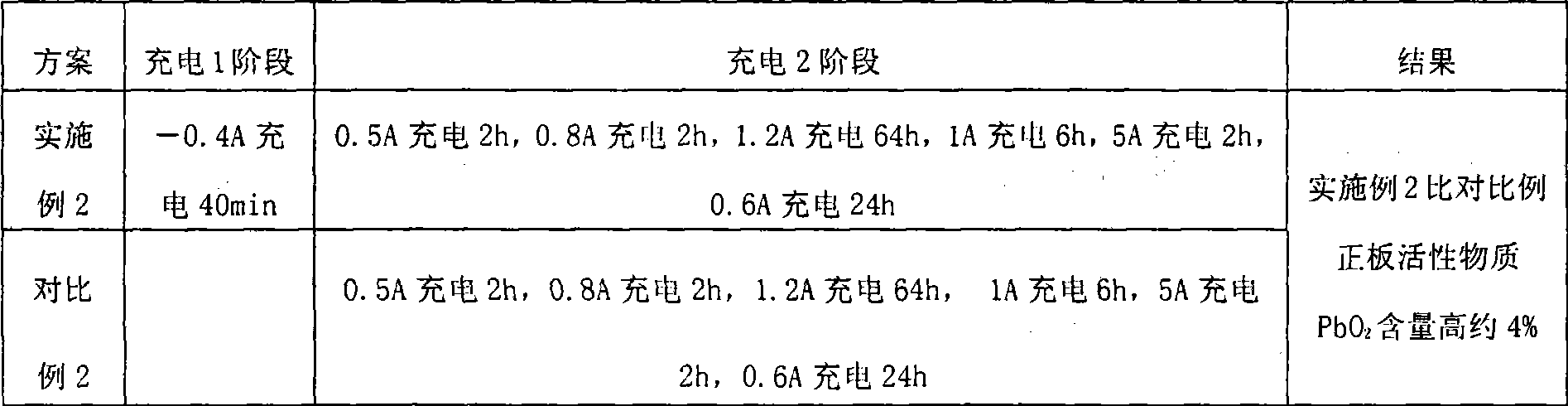

Embodiment 2

[0015] Take the 10Ah battery for electric bicycle in Example 1, the specific internalization steps are as follows: 0.4A reverse charge 40min, then forward charge, 0.5A charge 2h, 0.8A charge 2h, 1.2A charge 64h, 1A charge 6h, 5A Charge for 2h, 0.6A charge for 24h.

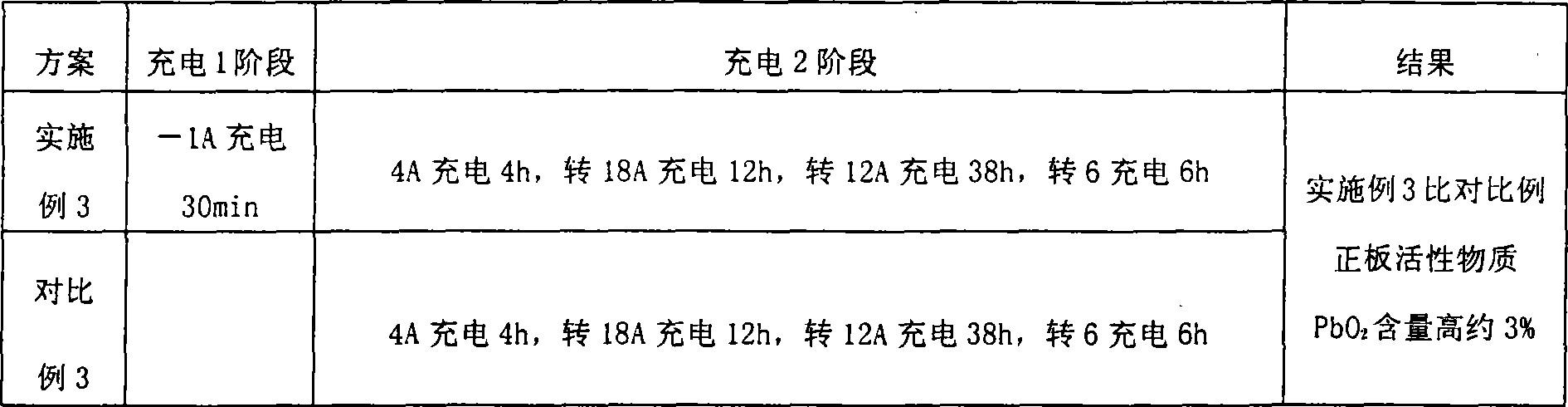

Embodiment 3

[0017] Take the photovoltaic energy storage battery 100Ah battery as an example. After the glue is filled, the internalization is carried out. The specific internalization steps are as follows: 1A reverse charging for 30min, then forward charging, 8A charging for 4h, 18A charging for 12h, 12A charging for 38h , Turn to 6A and charge for 6h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com