Double-roller impact crusher

A technology of impact crusher and impact roller, applied in the direction of grain processing, etc., can solve the problems that the discharge particle size cannot be strictly controlled, the structure of the double-roller vibrating crusher is complicated, and the spring system has many adjustment parameters, etc. Wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

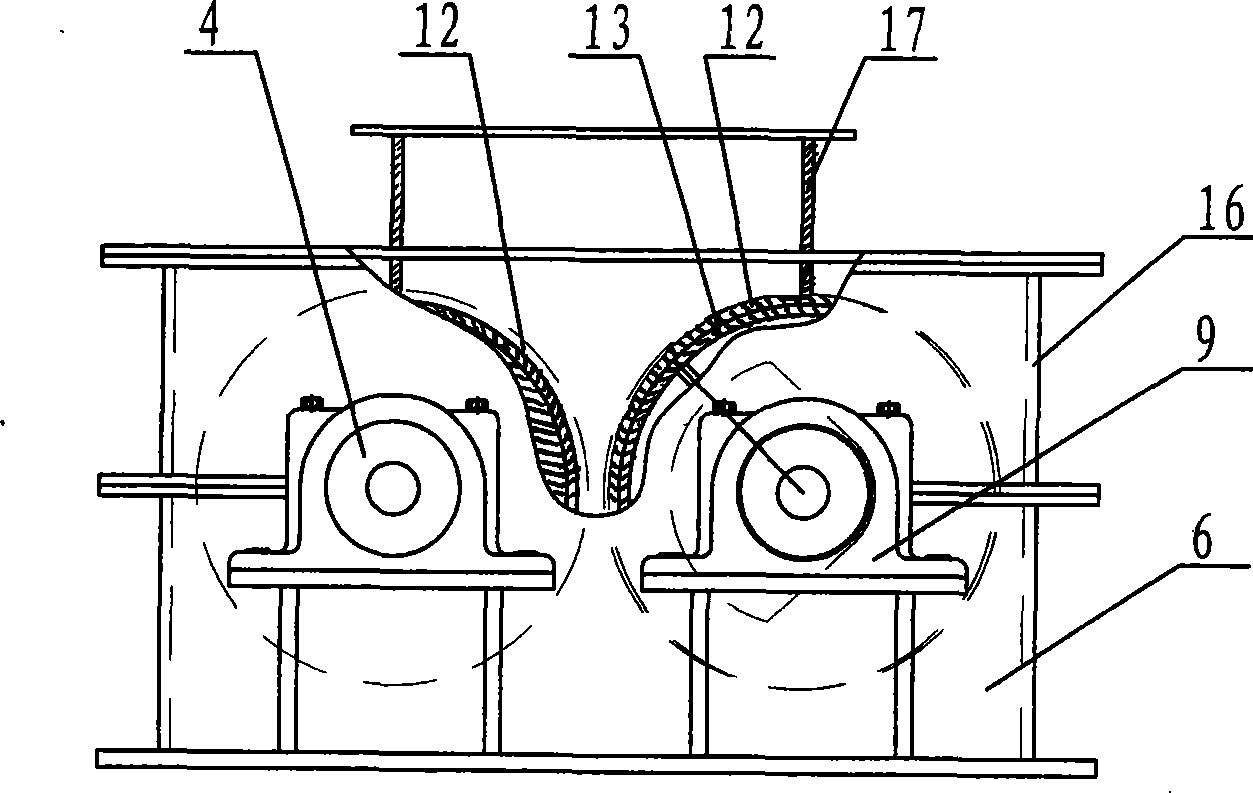

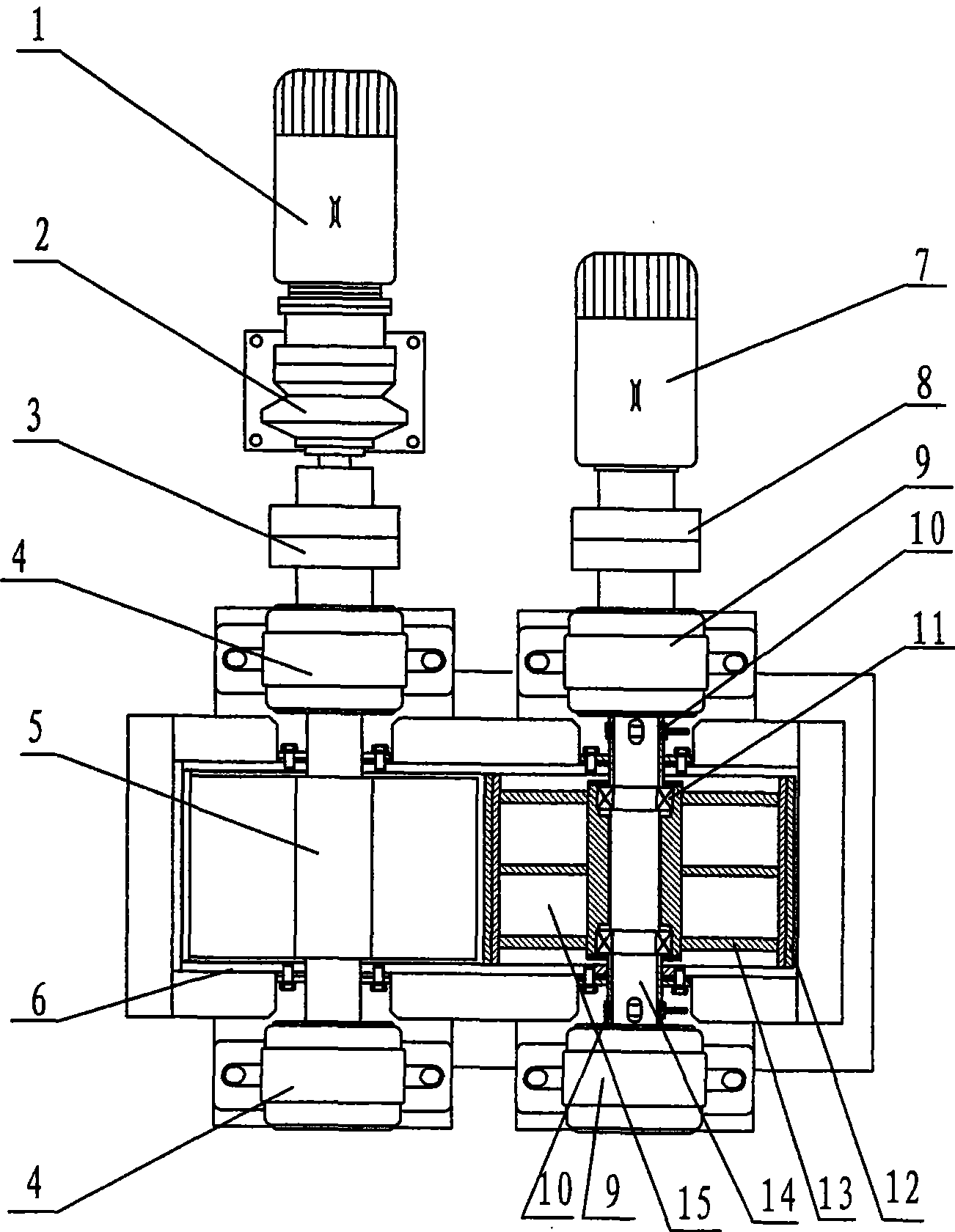

[0011] like figure 1 , figure 2 Shown: the utility model is directly installed on the foundation by lower casing 6, and bearing seat 4,9 is connected as a whole by rib plate and lower casing 6. The driving roller 5 and the impact roller 15 are arranged in parallel on the same plane, and are supported by the bearing housing 4 and the bearing housing 9 respectively. The upper casing 16 and the lower casing 6 are connected by a screw, and a feed hopper 17 is connected to the top of the upper casing 16, and the material is sent to the crushing chamber between the driving roller 5 and the impact roller 15.

[0012] The driving roller 5 is fixed on a straight shaft through a key connection, and the motor 1 drives the driving roller 5 to rotate at a low speed through a reducer 2 and a coupling 3; The eccentric part of the shaft 14 is directly driven by the motor 7 through the coupling 8 to rotate at a high speed, and the impact roller itself can rotate freely.

[0013] A pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com