Production process of pentadiene

A piperylene and production process technology, applied in the chemical industry, can solve problems such as failure to meet product specifications, excessive cyclopentadiene content, difficulty for operators, etc. Product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

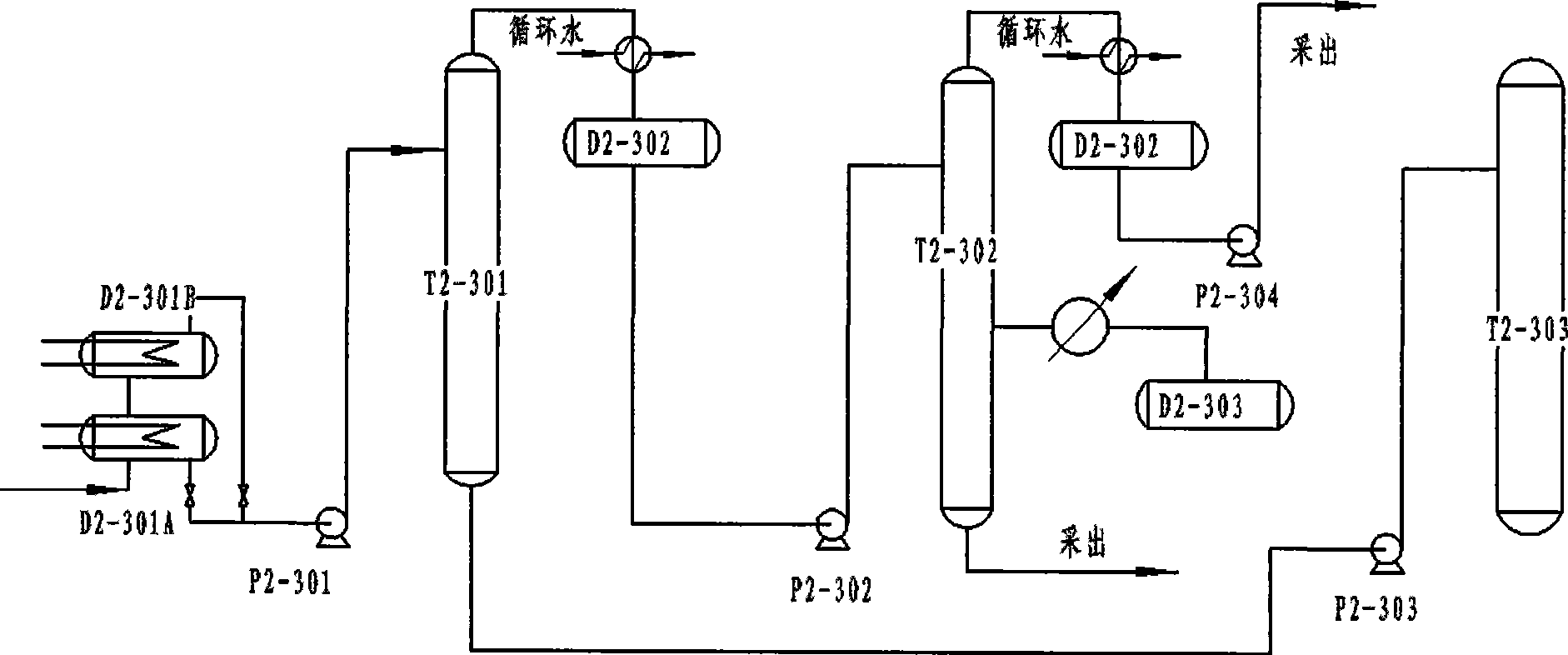

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 2 As shown, the material containing piperylene, dicyclopentadiene, a small amount of isoprene, cyclopentadiene, other small amounts of light components and heavy components is distilled from the carbon five out of the raw material tank group through the pump P2-301 Separation and distillation of piperpentadiene and dicyclopentadiene, the main components in the material, into the C5 distillation tower T2-301, and the separated dicyclopentadiene and other heavy components enter dicyclopentadiene The olefin separation tower T2-303, the separated piperylene and other light components enter the piperylene separation tower T2-302;

[0020] The C5 steaming raw material tank group is composed of two C5 steaming raw material tanks (D2-301A, D2-301B) connected in series;

[0021] After heat preservation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com