Method for forming bagged bulk solid of grouting borehole in concrete counterbalance solid and pore-creating method

A technology for concrete weighting and grouting holes, which is applied in construction, infrastructure engineering, etc., can solve the problems of inability to use concrete, inconvenient operation, high cost and high cost, and achieve the advantages of operability, simple structure, and the effect of saving drill bits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

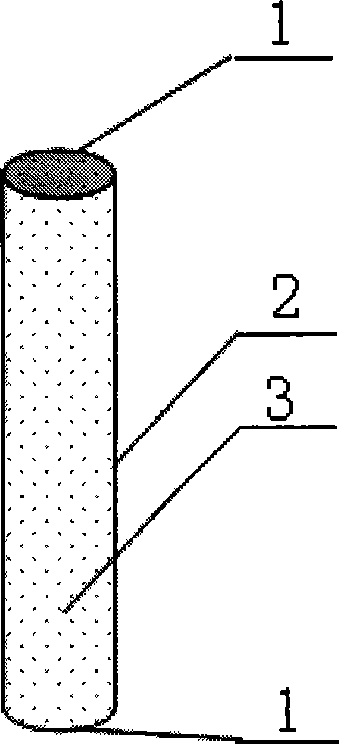

[0026] The bagged bulk solid of the present invention includes a tubular bag 2 and a filler 3 in the tubular bag 2, and a sealing rope 1 is tied at both ends of the tubular bag 2. The tubular bag 2 is made of a plastic bag with a circular shape and a length of 30-50 cm, and its diameter is consistent with the diameter of the grouting hole. The filling 3 in the tubular bag 2 is sand or mud.

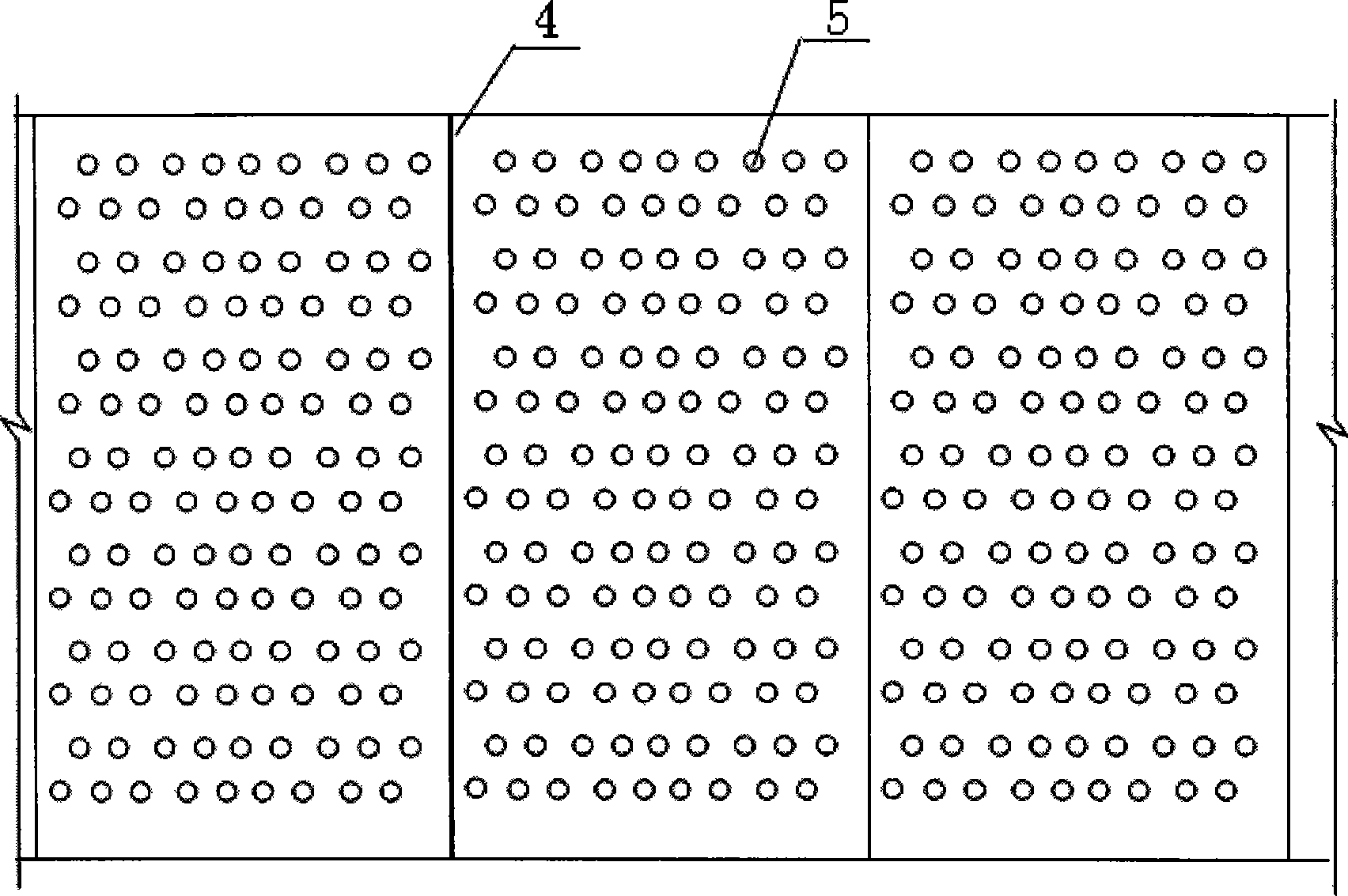

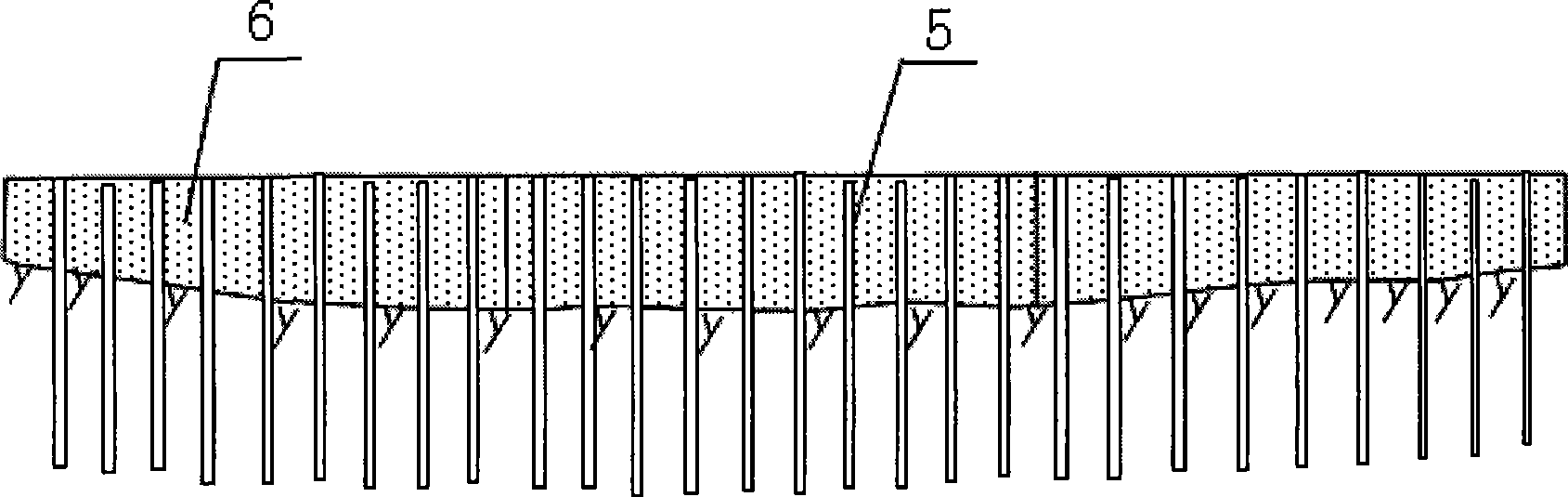

[0027] The hole forming method for forming grouting holes in the concrete weight includes the following steps:

[0028] 1. Make bagged bulk three-dimensional:

[0029] ① Roll the plastic into a circular tubular bag 2 with the diameter of the hole and the length of 30-50cm.

[0030] ②Put the filler 3 (preferably sand or mud) into each tubular bag, and seal both ends with a sealing rope 1 (preferably thin lead wire) to form a length of 30-50cm and a diameter of the hole. The cylindrical bag is packed in bulk 7.

[0031] 2. Measure the position of the hole to be released before pouring the weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com