Same-well production technique column for low-permeation horizontal well

A technology of production and injection in the same well and process pipe string, which is applied in wellbore/well components, production fluids, earth-moving drilling and production, etc., can solve the problems of high cost, complex facilities, inability to apply, etc., and achieves convenient construction and low investment. , Improve the effect of injection-production correspondence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

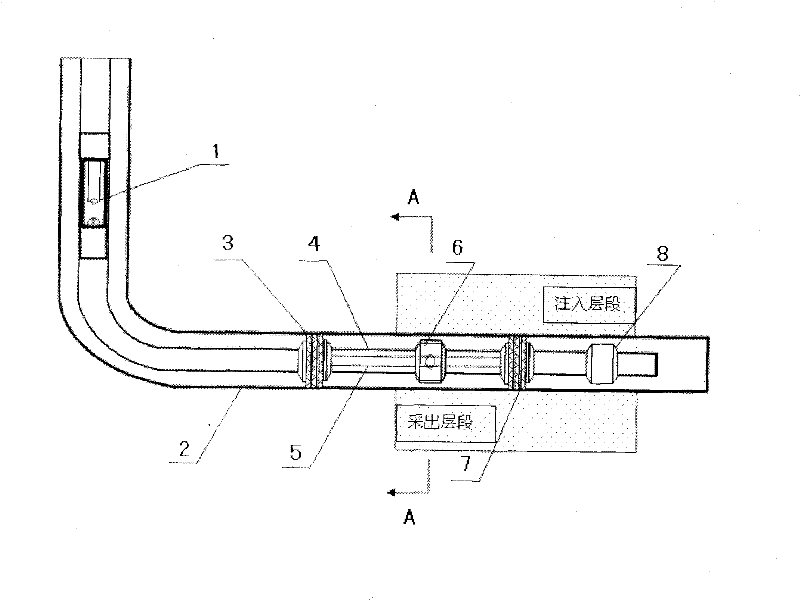

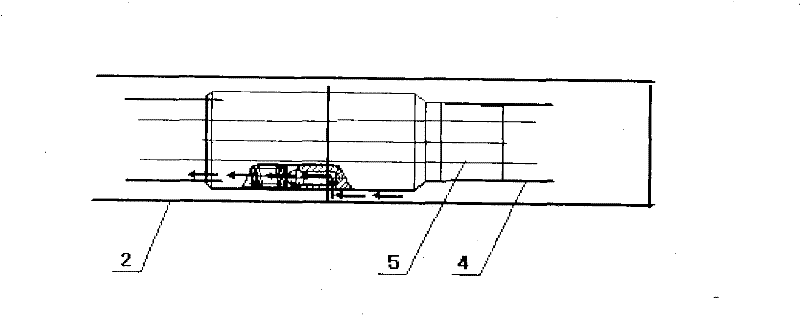

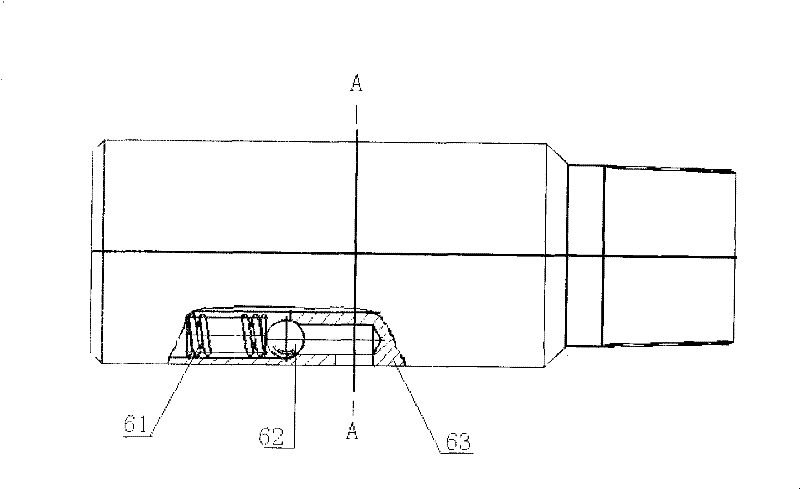

[0014] refer to Figure 1-Figure 4 A low-permeability horizontal well production-injection process string in the same well, including a tubing string, a pump, a bridge packer A, a bridge packer B, an inner pipe, a bridge diverter valve, and an injector. The pump 1, the bridge packer A3, the bridge diverter valve 6, the bridge packer B7 and the injector 8 are installed and connected to the tubing 4 in sequence. The inner pipe 5 is installed in the tubing 4, the middle part is connected with the bridge diverter valve 6, and the two ends are connected with the bridge packer A3 and the bridge packer B7.

[0015] The pump 1 is located at the vertical well section inside the casing 2 . The bridge packer A3 is located in front of the production zone, and the bridge packer B7 is located between the production zone and the injection zone in the production zone. The bridge diverter valve 6 is located at the production interval in the production layer, on which a diversion conversion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com