Improved vacuum rake type dryer

A rake dryer and vacuum technology, used in non-progressive dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of high electricity and steam consumption, unstable product quality, and low production efficiency. , to achieve the effect of reducing processing cycle, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

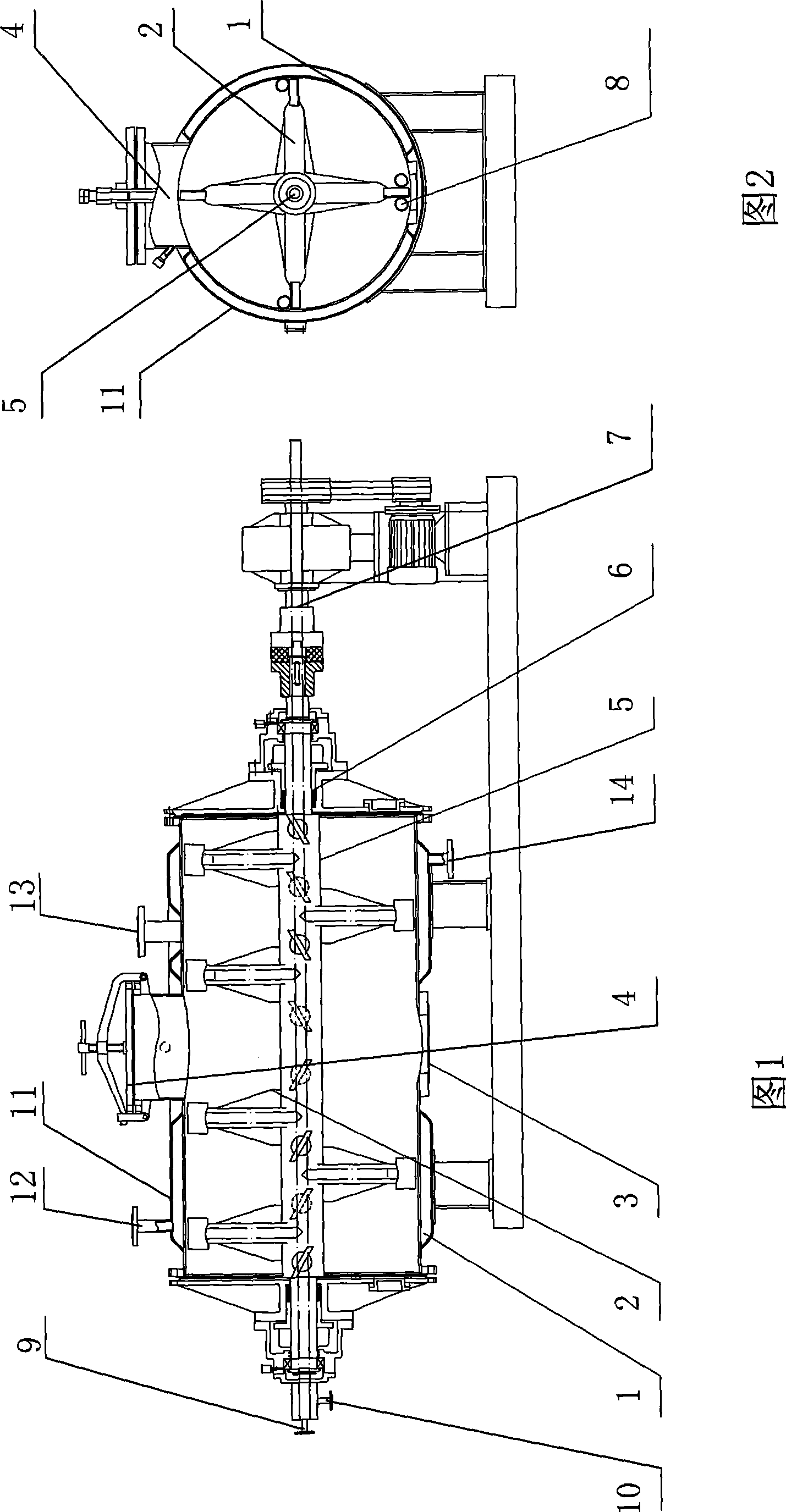

[0009] see picture 1, figure 2 , the present invention comprises housing 1, rake tooth 2, stirring shaft 5, transmission device 7, and rake tooth 2 is fixed on the stirring shaft 5, and stirring shaft 5 runs through housing 1, and stirring shaft 5 is connected with transmission device 7, and housing 1 is provided with a jacket, the stirring shaft 5 and the rake tooth 2 are hollow tubes, and the stirring shaft 5 and the rake tooth 2 are connected internally; the outer end of the stirring shaft 5 is equipped with a steam inlet 9 and a steam outlet 10. In the figure, 3 is a discharge device, 4 is a feeding device, 6 is a sealing device, 8 is a crushing rod, 11 is a jacket, 12 is a jacket steam inlet, 13 is a vacuum port, and 14 is a jacket steam outlet. mouth. The feeding device 4 and the discharging device 3 are arranged above and below the casing 1 respectively; crushing rods 8 are placed in the casing, and a crushing rod 8 is placed between every two rake teeth 2 .

[0010] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com