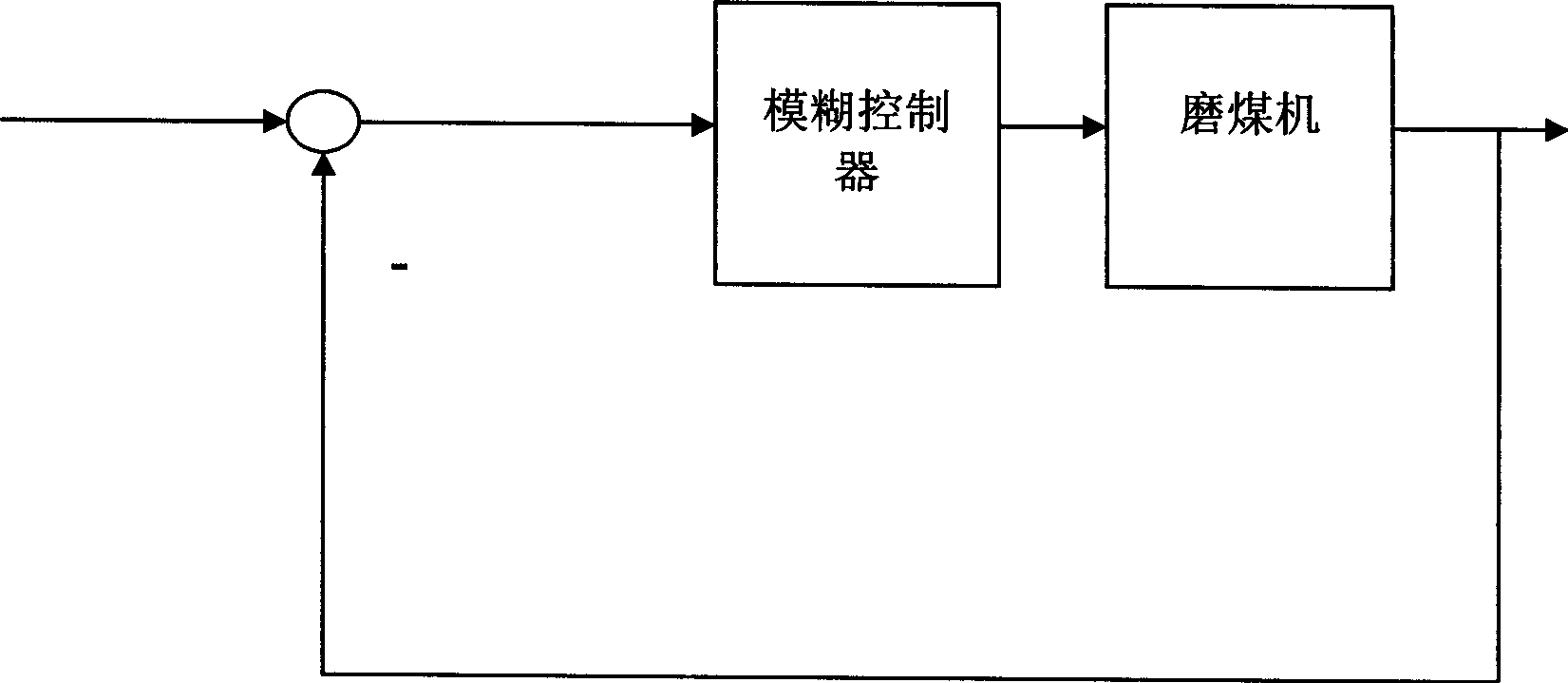

Fuzzy control method for direct-blowing type coal mill

A technology of fuzzy control and fuzzy controller, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of automatic control system not being able to optimally control, large inertia, large time delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] 1. The present invention uses a fuzzy intelligent control method, wherein the fuzzy control part is realized by a fuzzy controller with intelligent characteristics.

[0007] 2. The fuzzy controller with intelligent features referred to in the present invention includes the theoretical realization form of the fuzzy controller and the realization form of the fuzzy controller device.

[0008] 3. The theoretical implementation form of the fuzzy controller included in the fuzzy controller referred to in the present invention is realized in the following manner:

[0009] 3.1, the fuzzy controller can simultaneously activate several rules to varying degrees, and each rule reflects different aspects of the overall information

[0010] 3.2. The controller performs fuzzy reasoning according to the pre-determined reasoning method, and obtains the fuzzy output as the fuzzy membership function.

[0011] 3.3, the controller defuzzifies the decision to obtain precise control instruct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com