Low-pressure difference linear voltage stabilizer with high power supply rejection ratio

A high power supply rejection ratio, low dropout linear technology, applied in the direction of instruments, electric variable adjustment, control/regulation system, etc., can solve the problem of small main zero point of PSRR, achieve the effect of improving PSRR characteristics and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

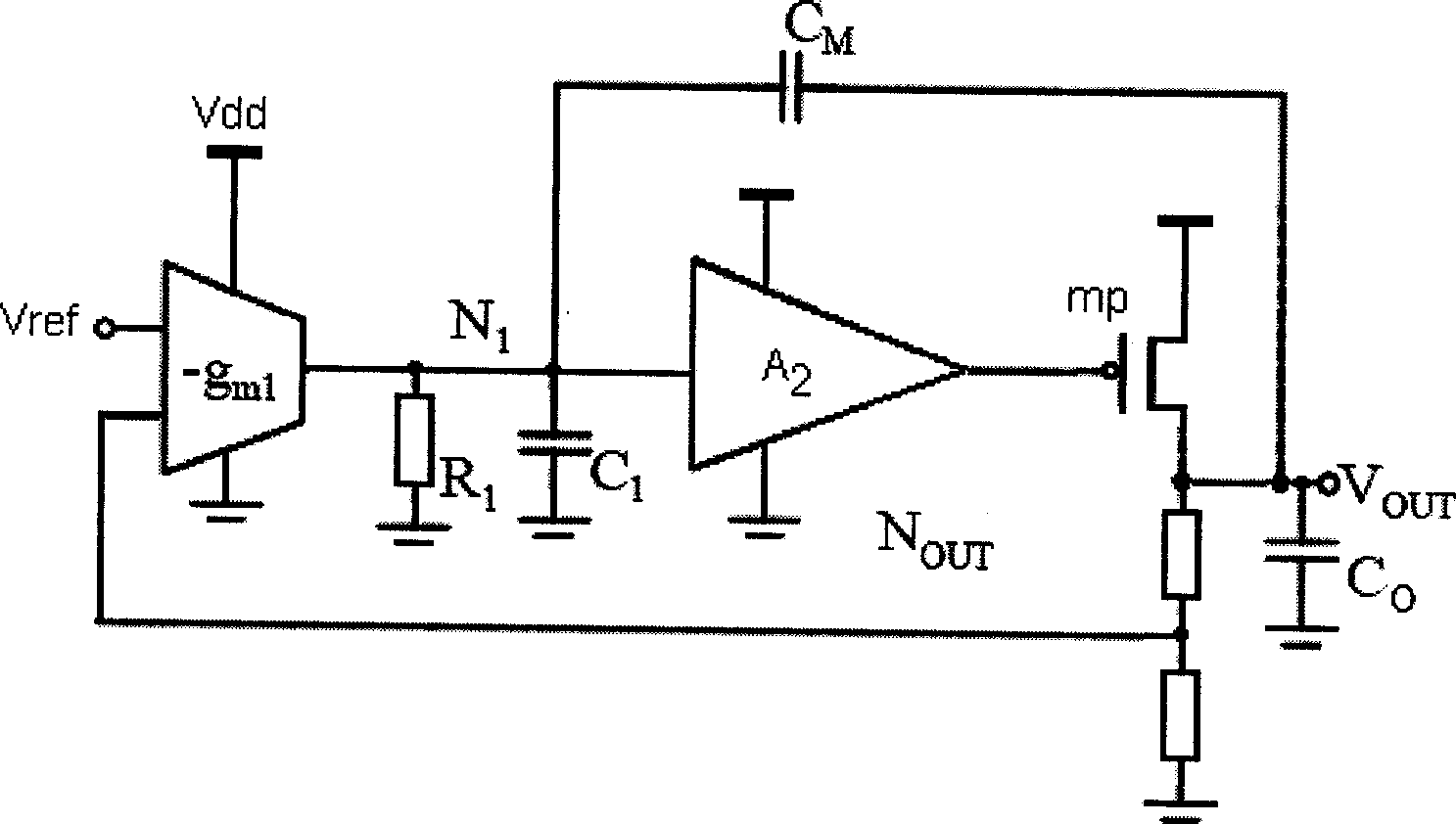

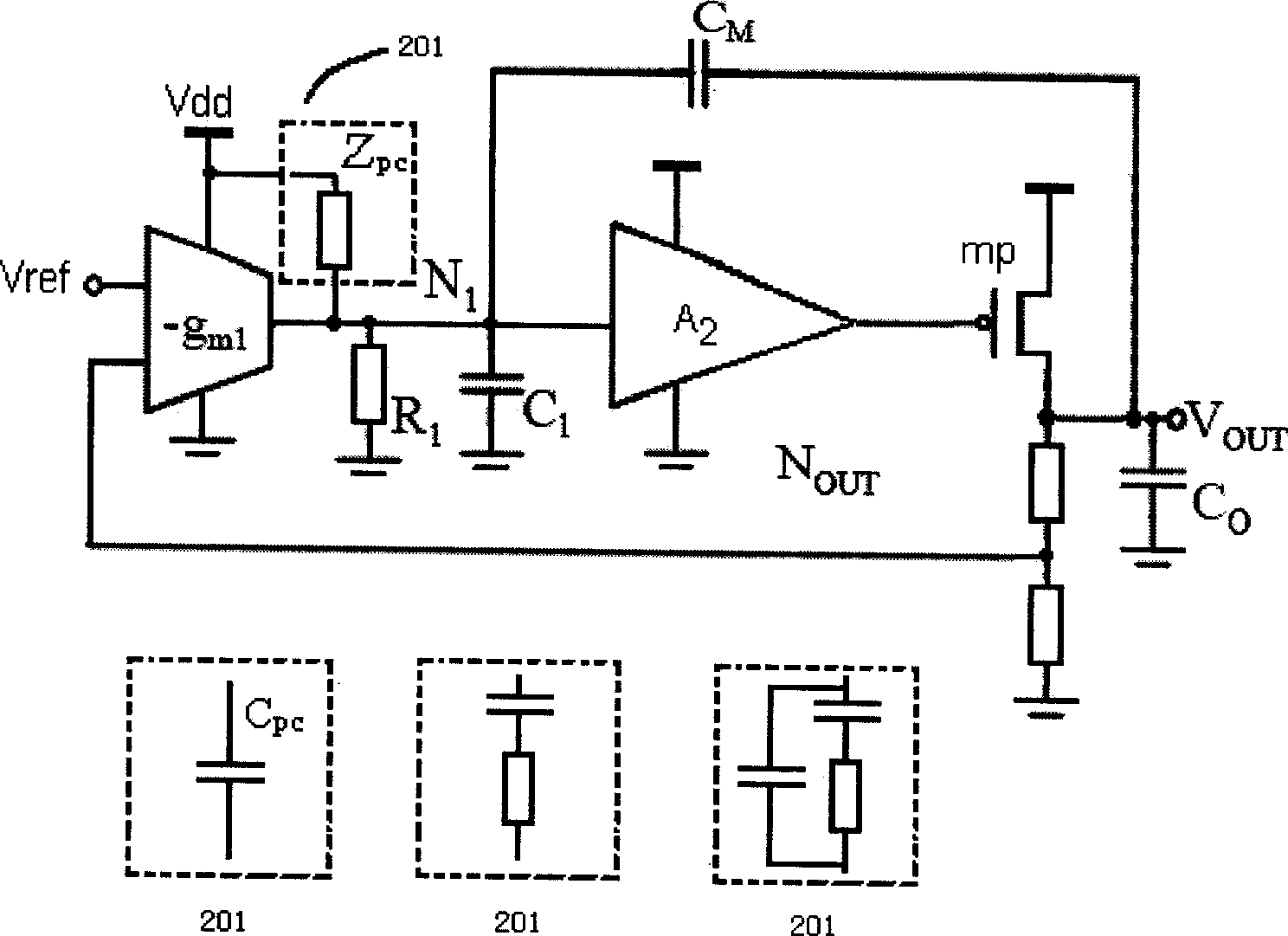

Method used

Image

Examples

Embodiment Construction

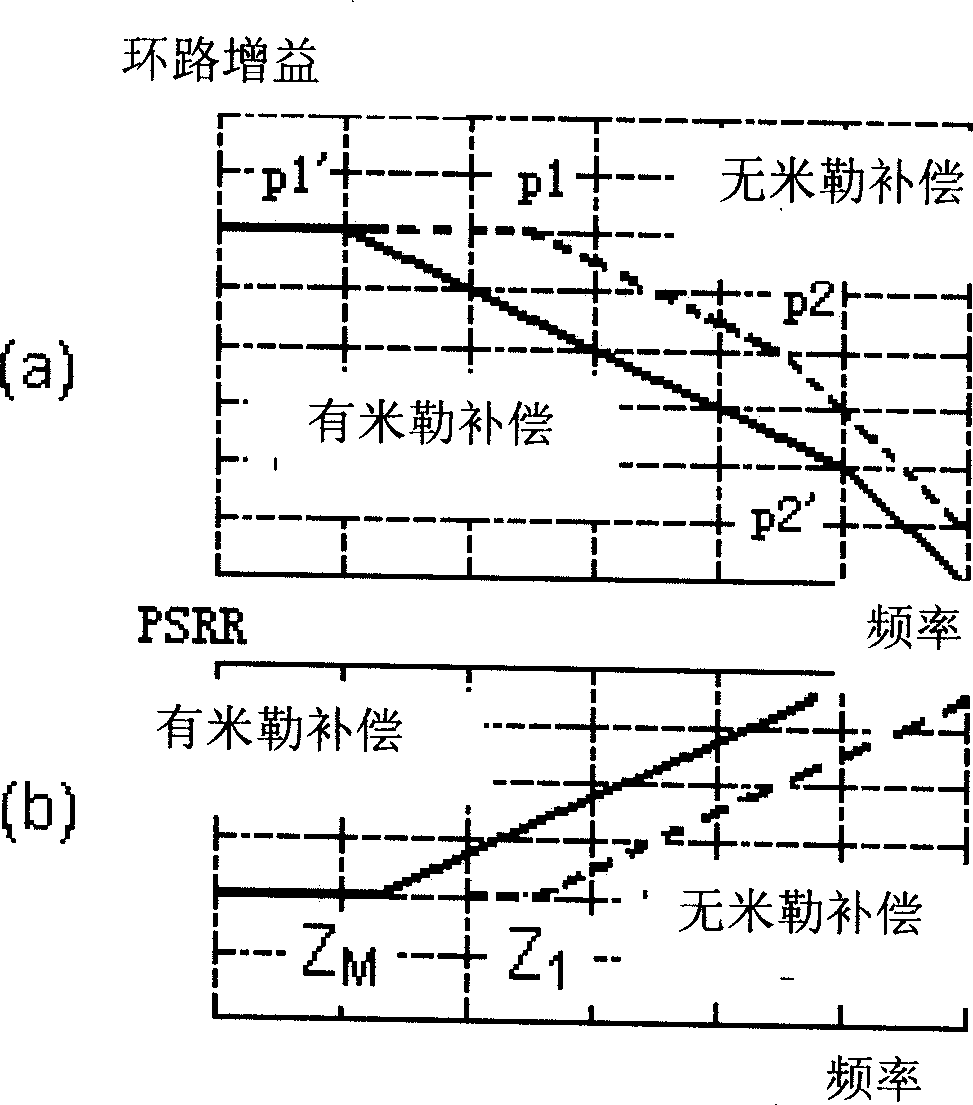

[0015] When the LDO does not use the Miller capacitor, the zero point of the PSRR curve of the LDO is given by (1).

[0016] Zero 1 = 1 R 1 C 1 - - - ( 1 )

[0017] After adopting the Miller compensation, the zero point of the PSRR curve of LDO is given by (2) test.

[0018] Zero M = 1 R 1 C M - - - ( 2 )

[0019] Among them, R 1 , C 1 and C M are the output resistance of the first-stage amplifier, that is, the error amplifier, the equivalent output capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com