Method for forming light-transmitting regions and image sensing apparatus

A technology for image sensing devices and light-transmitting regions, which is applied in radiation control devices, semiconductor devices, electrical components, etc., can solve problems such as long manufacturing time, inconsistent exposure consistency and reproducibility, high manufacturing cost of photolithography technology, etc. To achieve the effect of saving manufacturing cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

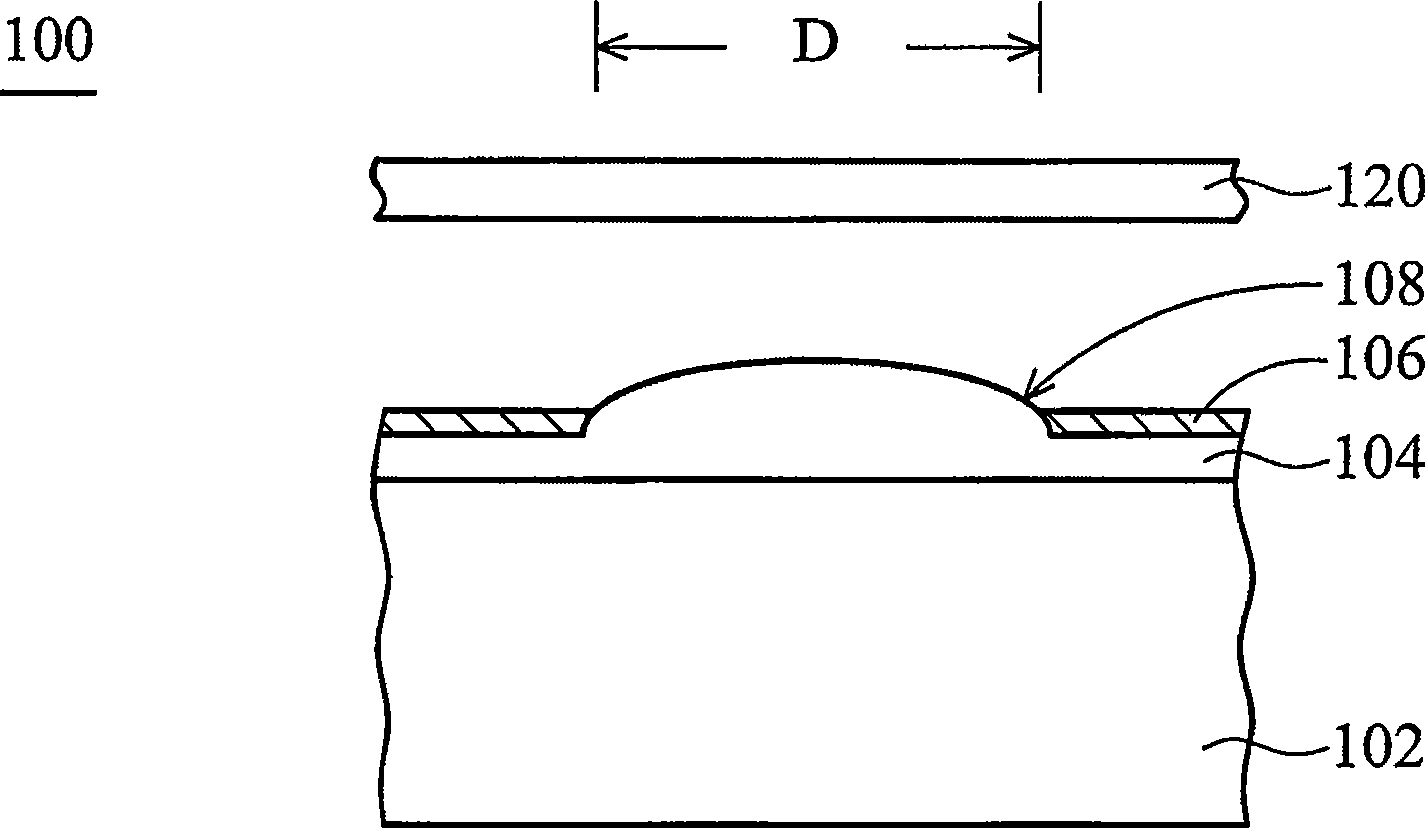

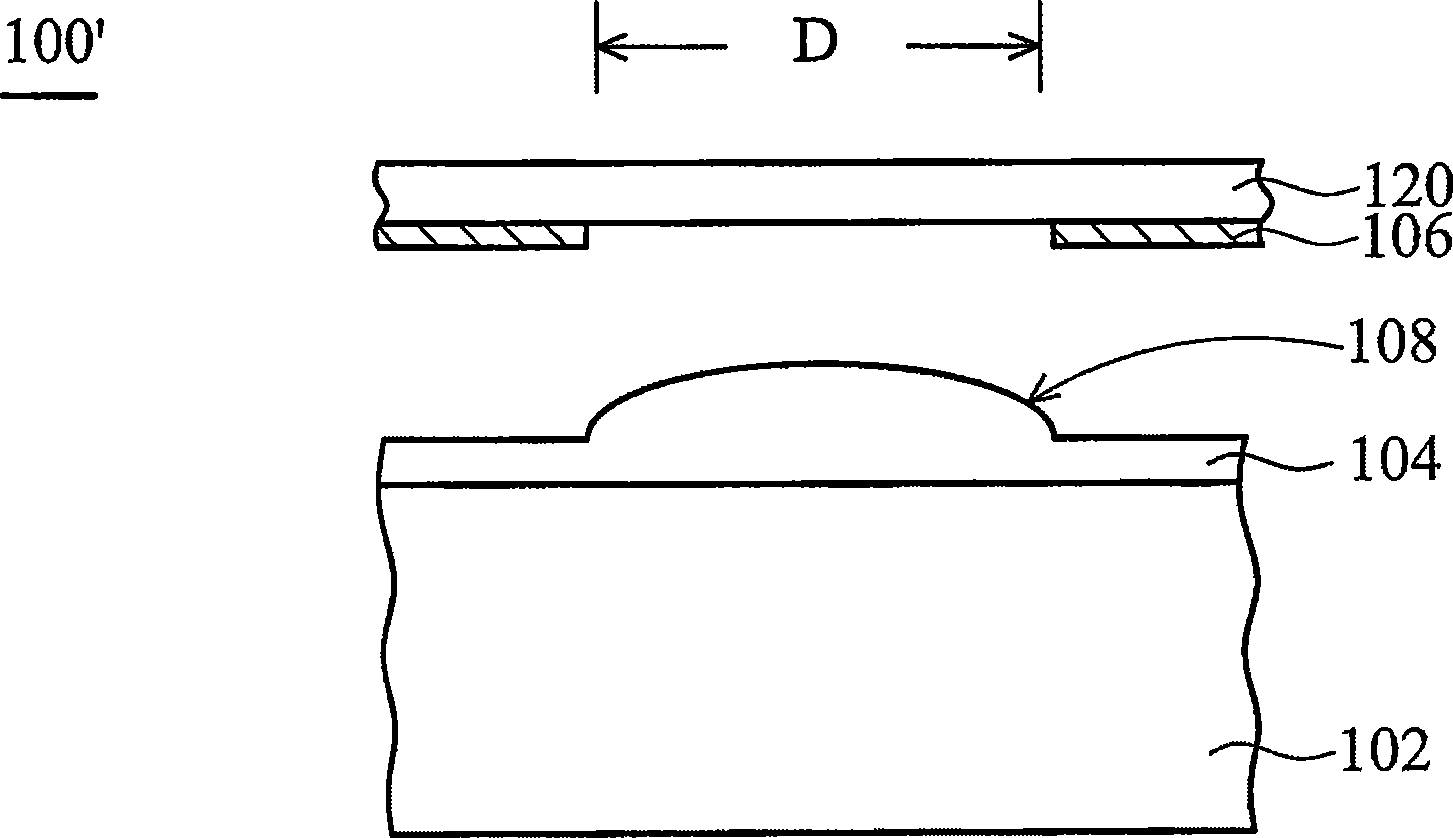

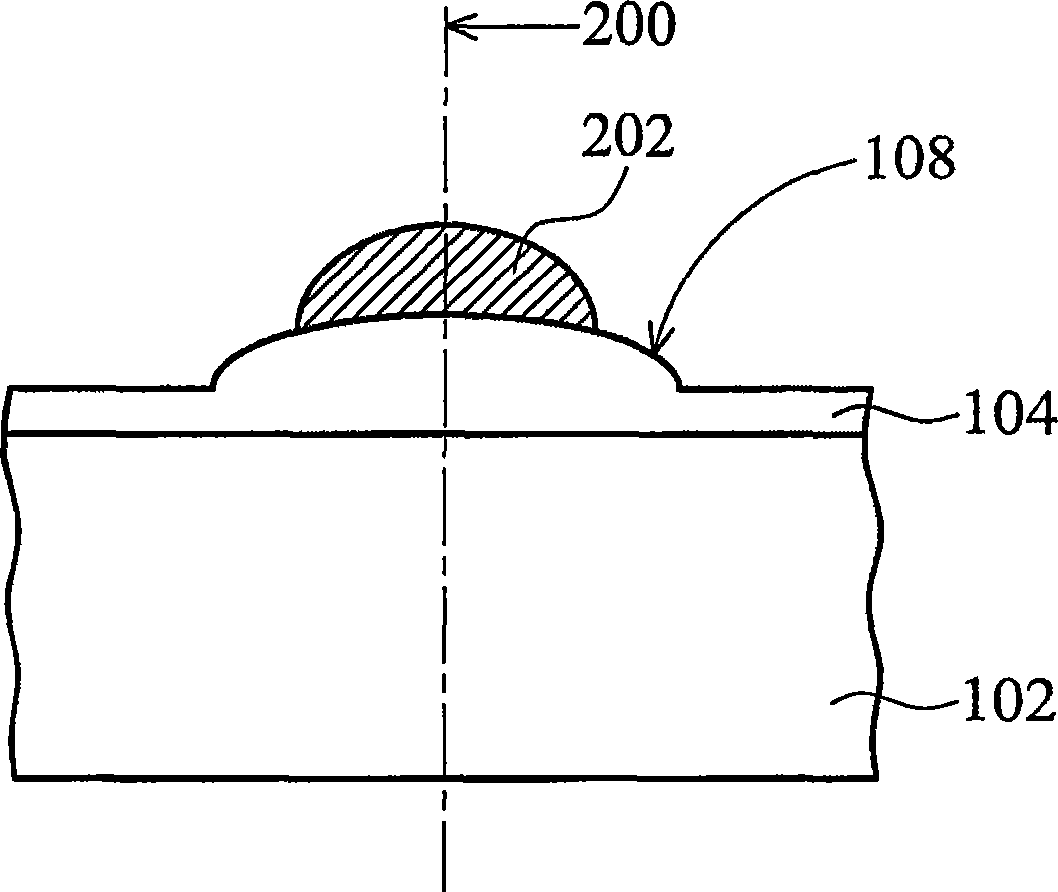

[0047] figure 1 and figure 2 It is a series of cross-sectional schematic diagrams, respectively partially showing image sensing devices according to different embodiments of the present invention.

[0048] Please refer to figure 1 , which shows an image sensing device 100 , which includes an image sensing structure 102 , a microlens 104 , a light-shielding layer 106 and a light-transmitting substrate 120 . exist figure 1 The image sensing structure 102 is shown here as a planar structure, but the image sensing structure 102 may include an image sensor such as a charge-coupled device image sensor, a complementary metal-oxide semiconductor image sensor, or other types of image sensors. not shown), including a color filter layer (not shown) of a plurality of different color filters such as red, green or blue, a plurality of interconnected metal layers (not shown) and for insulating the above-mentioned interconnected Functional components such as multiple inter-metal dielectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com