Method and apparatus for auto-focussing infinity corrected microscopes

An automatic focus and microscope technology, applied in the field of optical microscopes, can solve problems such as performance limitations of efficient AF equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In general, the present invention provides a method and system for autofocusing an infinity corrected microscope. The invention is particularly useful in thin film transistor (TFT) array inspection, photolithographic mask inspection, silicon wafer inspection, and micromachining and coordinate measuring machines (CMM).

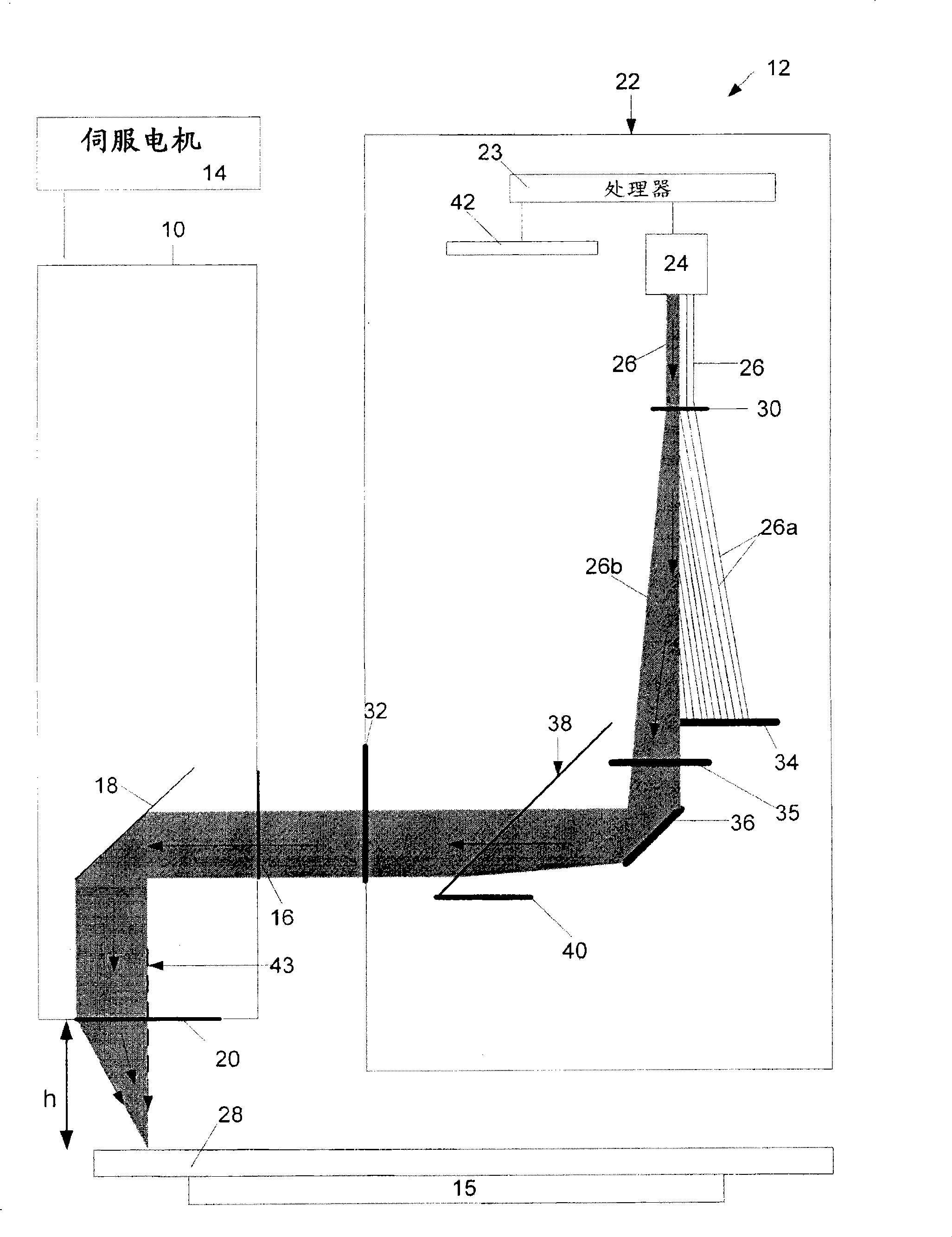

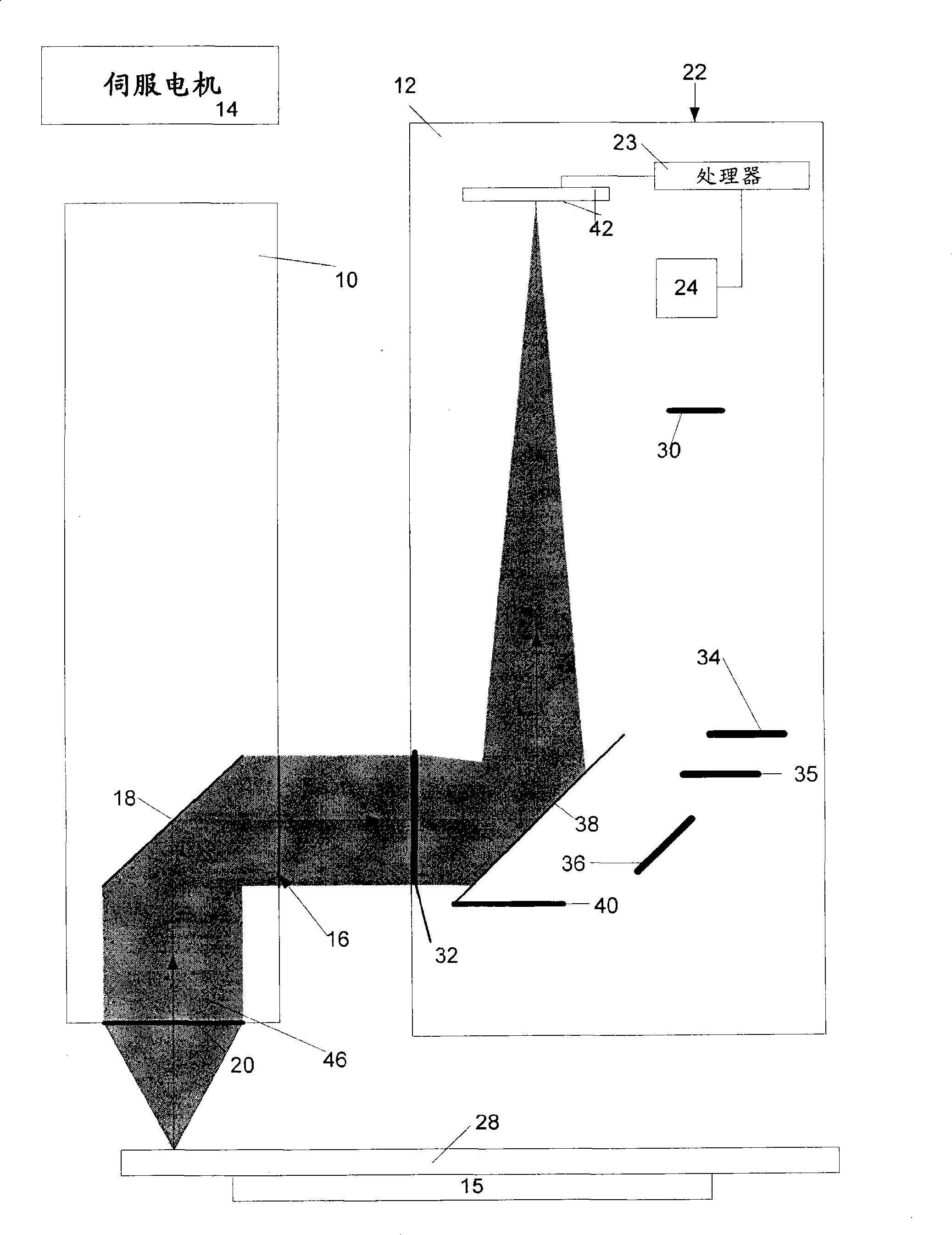

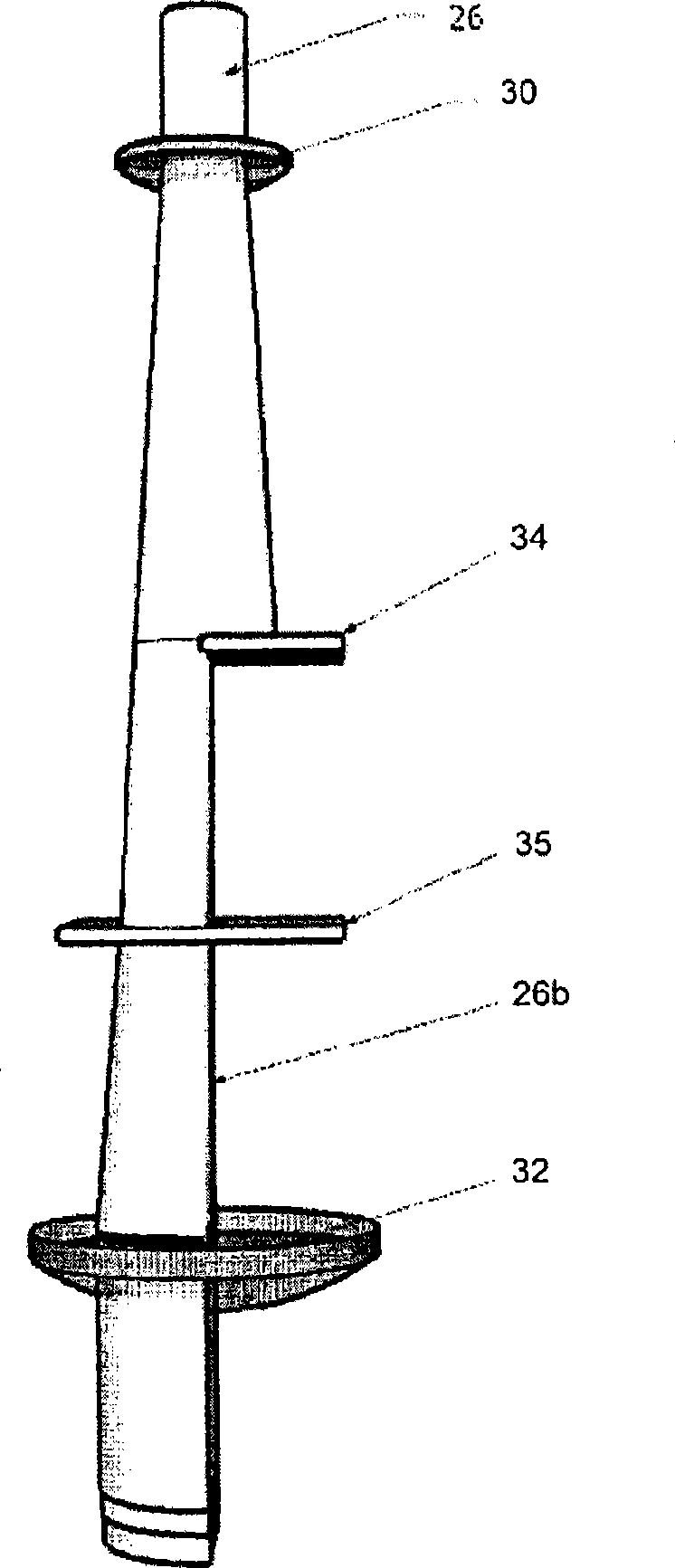

[0029] go to Figures 1a to 1d , a schematic diagram of an embodiment of an autofocus device for an infinity-corrected microscope is shown. Figure 1a For a schematic view of the device providing the output beam, Figure 1b is a schematic view of the reflected beam after the output beam has been reflected off the sample, and Figure 1c with 1d is the 3D view of the output beam.

[0030] exist Figure 1a In , an infinity-corrected microscope 10 is shown having an autofocus device 12, such as a detector. Although shown discretely, it is understood that device 12 may be integrated within microscope 10 , or mounted within, and typically an accessory to, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com