Heating element

A heating element and heating plate technology, which is applied in printing and other directions, can solve the problems of simultaneous driving of heating elements, adding heating elements, printer power supply can not be loaded, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Some typical embodiments embodying the features and advantages of the present application will be described in detail in the description in the following paragraphs. It should be understood that the present case can have various changes in different aspects without departing from the scope of the present case, and the descriptions and diagrams therein are used for illustration in nature rather than limiting the present case.

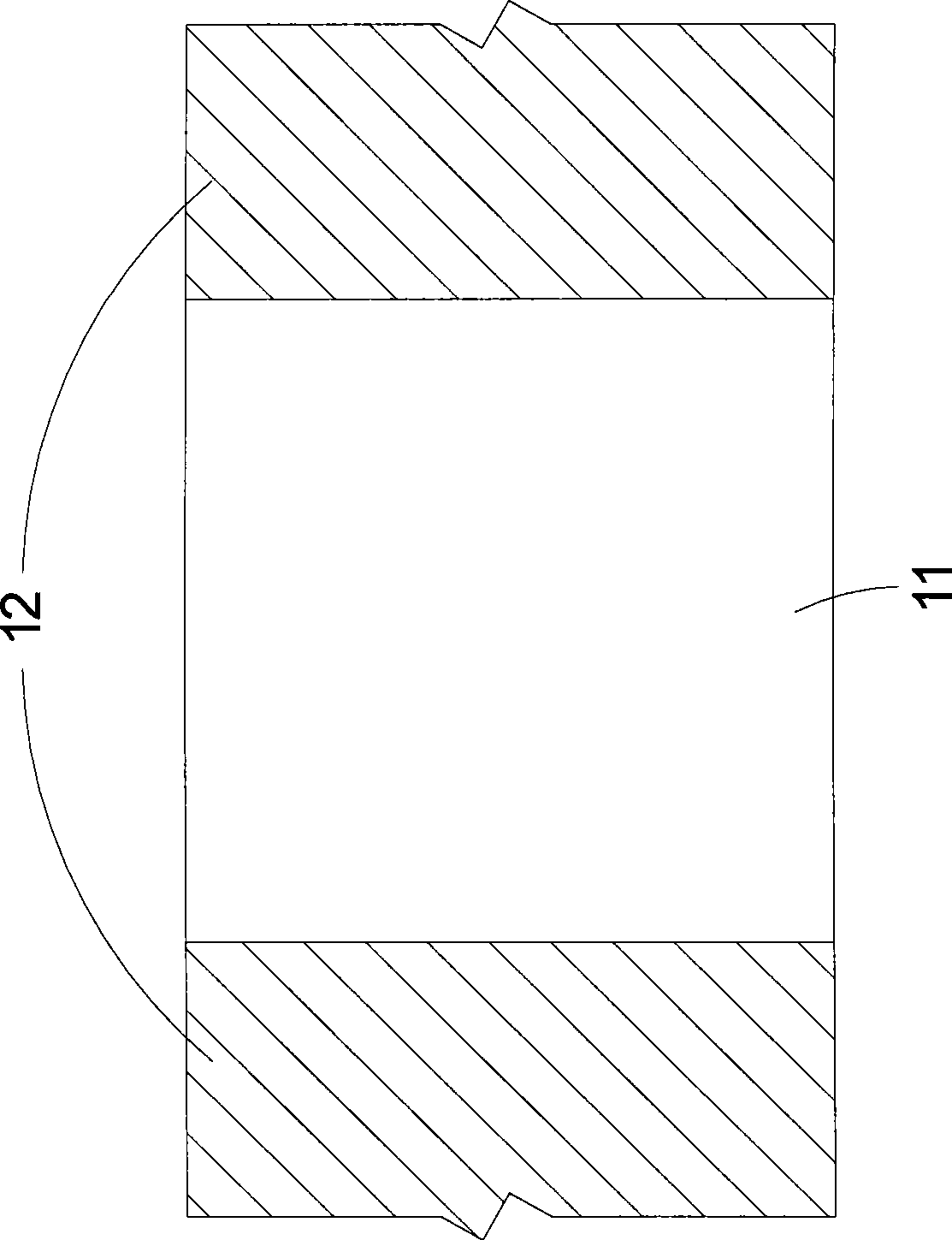

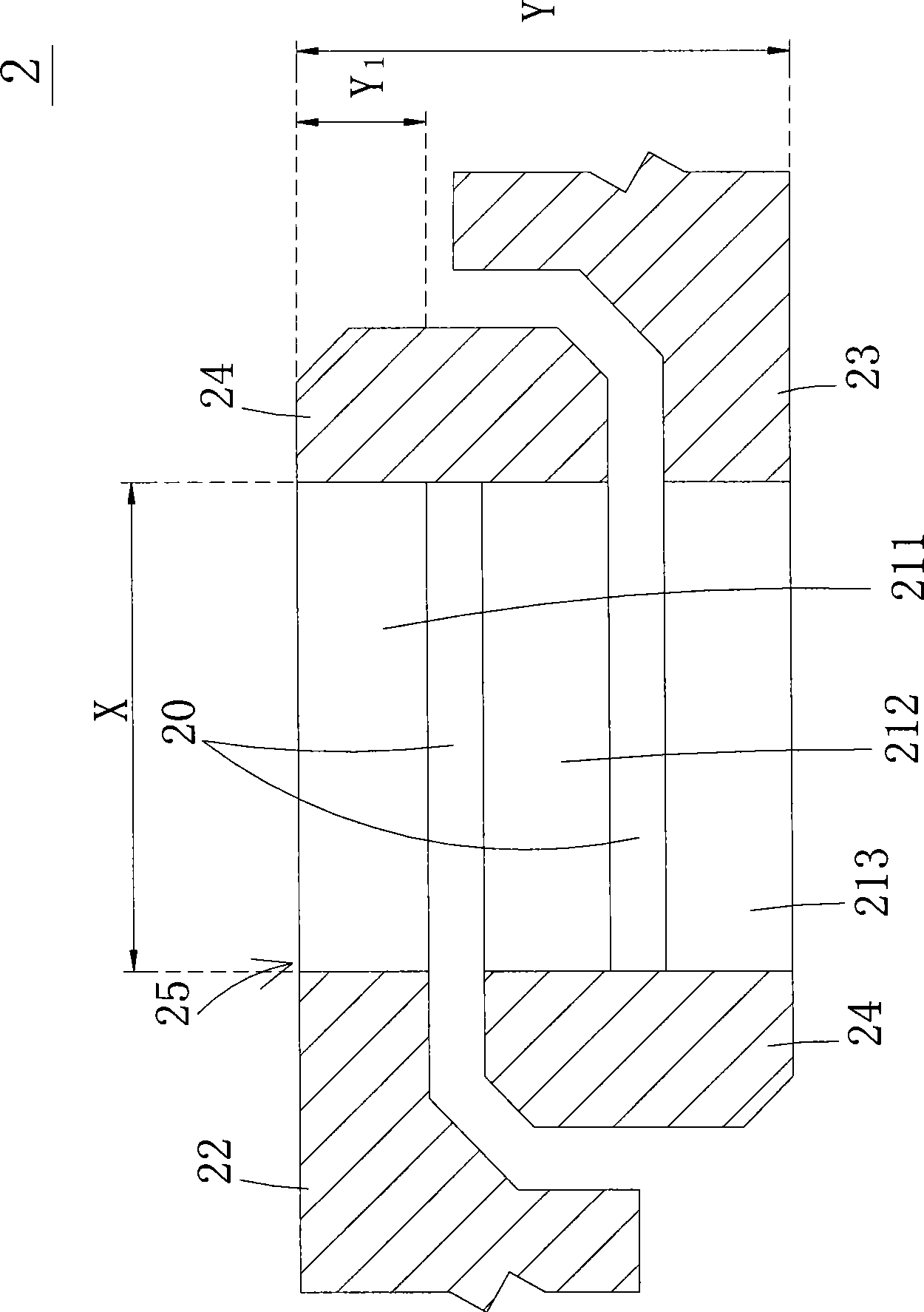

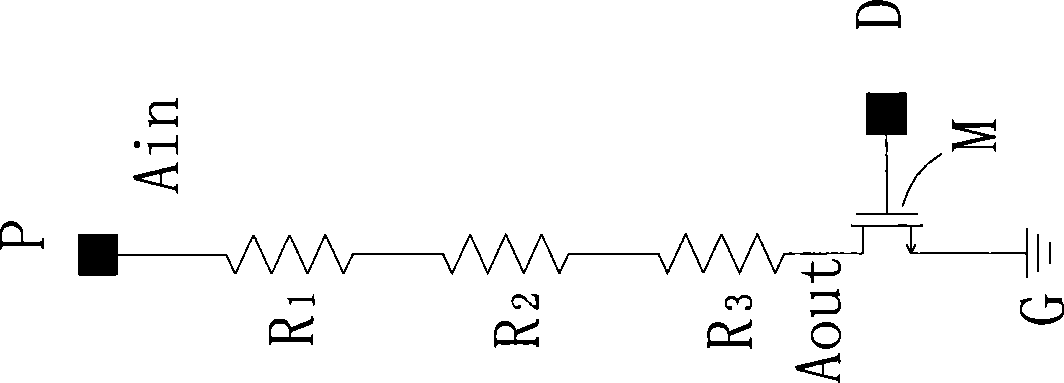

[0032] The heating element in this case is mainly applied to the structure of the inkjet head of the printing device, such as the structure of the inkjet head of the inkjet printer (not shown), but not limited thereto. Please refer to FIG. 2( a ), which is a schematic diagram of the heating element of the first preferred embodiment of the present case. As shown in the figure, the heating element 2 mainly includes a plurality of heating plates 211-213, an input terminal 22, an output terminal 23, and a conductive layer 24 connecting two adjacent he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com