Brake mode of band brake and brake thereof

A technology of band brakes and brake bands, which is applied in the direction of drum brakes, brake types, brake parts, etc., can solve the problems of increased manufacturing cost, poor braking effect, and difficulty in popularization, and achieves small impact, low cost, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

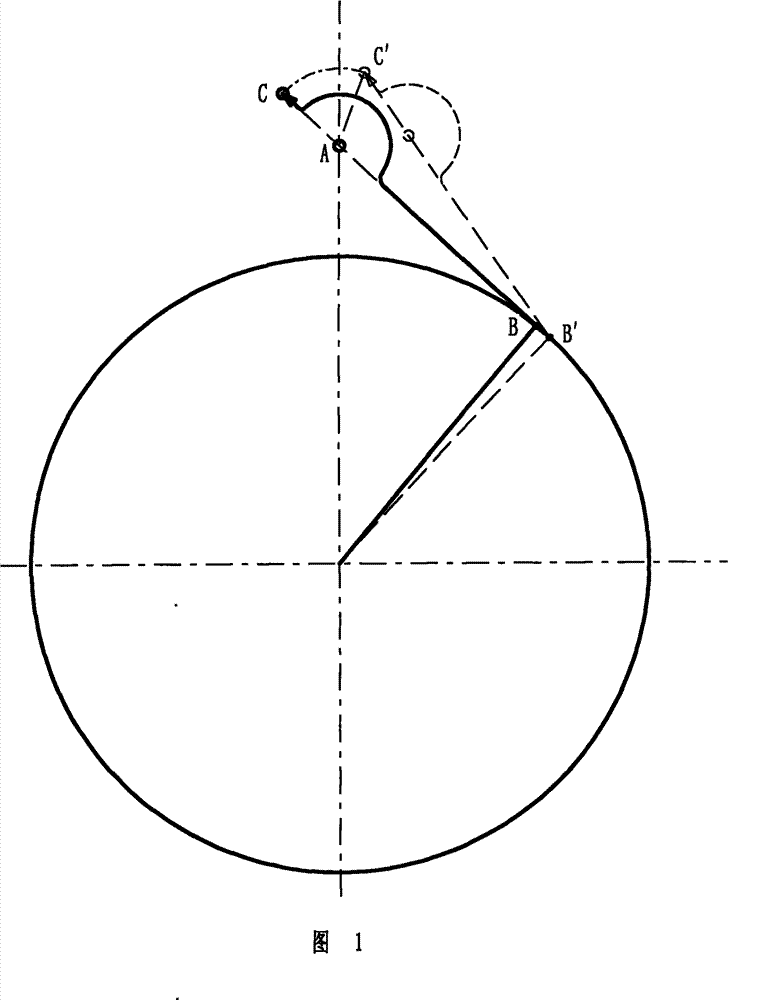

[0030] In conjunction with Fig. 1, the braking method of the band brake is characterized in that the tightening end of the brake band assembly is provided with a self-locking device and an adjusting device, the fixed end is provided with a buffer device, and the brake lever is provided with a limiting device, so that The tension point and the fixed point are the rotation center of the brake lever and the tangent point between the tension end of the brake band assembly and the outer circle of the brake wheel. During braking, the three points are located on a straight line to realize two-way braking.

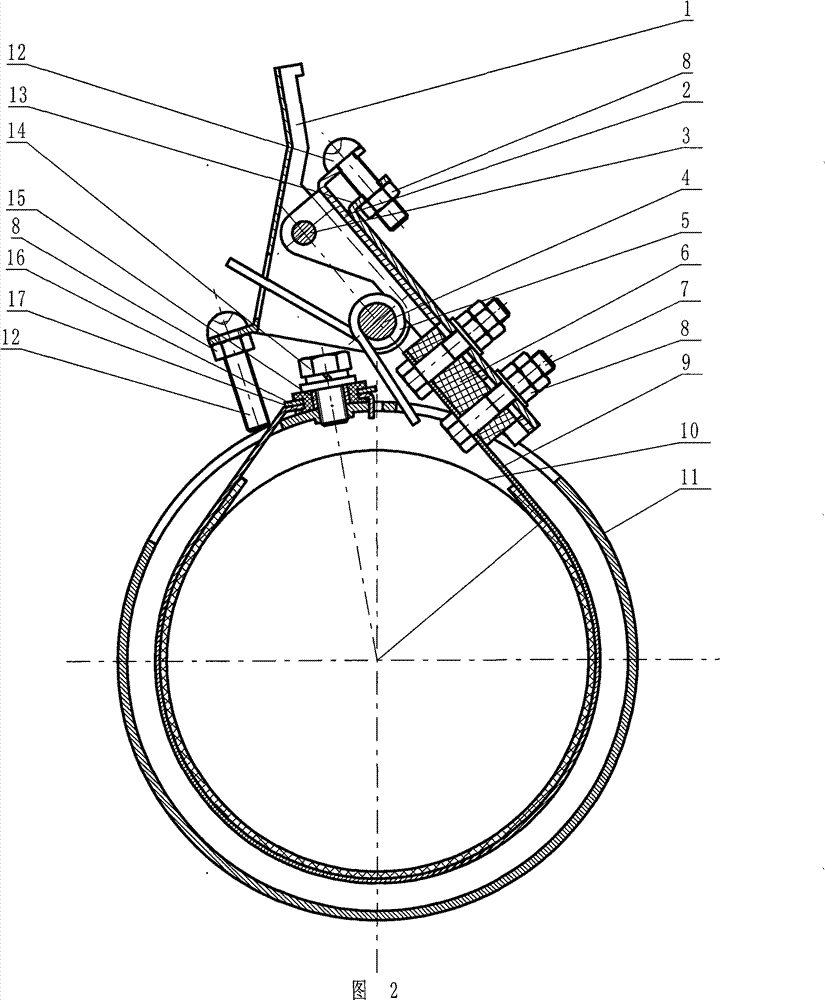

[0031] Combined with Figure 2, the two-way acting connecting plate self-locking type band brake adopts connecting plate self-locking device, including brake lever 1, connecting plate 2, cylindrical pin 3, fixed shaft 4, return spring 5, elastic block 6, bolt 7 , nut 8, brake band assembly 9, brake wheel 10 and support support 11; the fixed shaft 4 is fixed on the support support 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com