Group-type voltage-withstanding test method

A test method and withstand voltage technology, applied in the direction of testing dielectric strength, fault location, etc., can solve the problems of not meeting the requirements of rapid group test of cable withstand voltage, not suitable for withstand voltage test methods, and not having waterproof performance, etc. Achieve the effect of shortening detection time, shortening processing time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

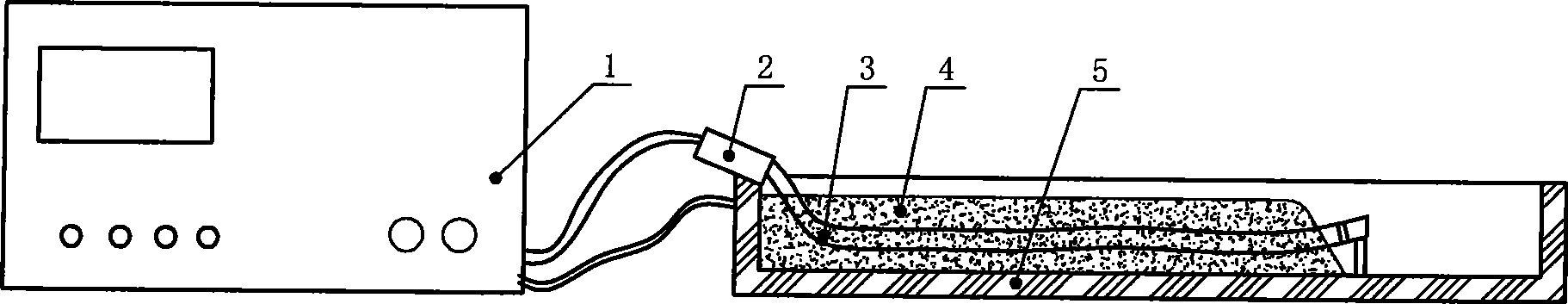

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

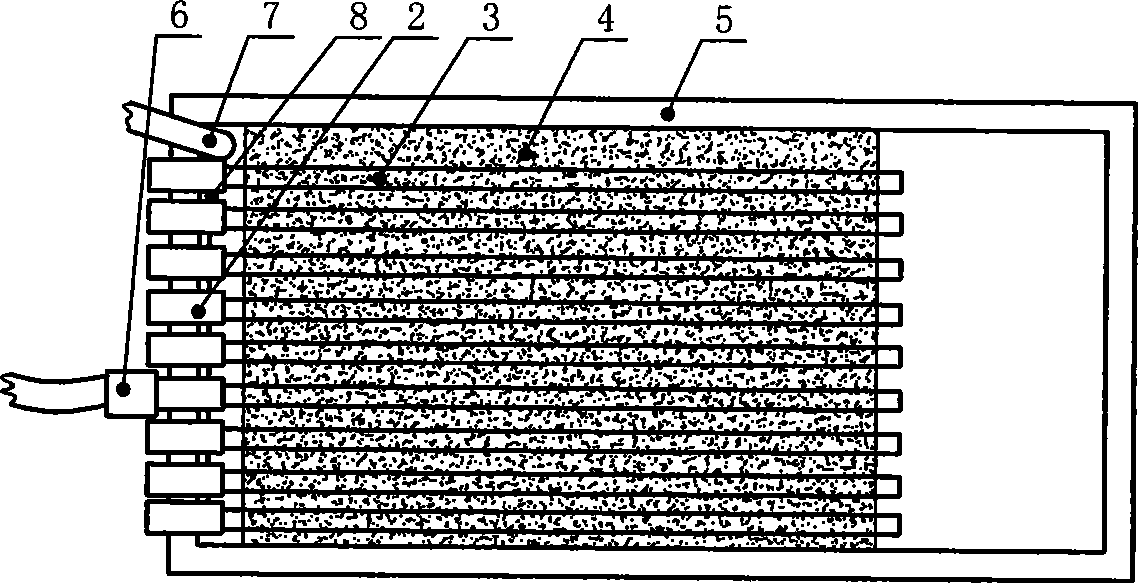

[0023] A group-type withstand voltage test method, including the steps of placing the tested cable 3 in the conductive medium of the test container 5, and the step of using the pressure device 1 to pressurize the tested cable, and the step of detecting cable defects, and its innovations In that: the method also includes the following steps:

[0024] Arrange the cables in bundles, such as figure 2 As shown in , the conductors at one end are connected to each other with conductive material 8, specifically: align one end of the cable with terminal 2 and arrange them in parallel, and use conductive material to connect the terminals connected to the end of the cable in sequence make them conduct each other.

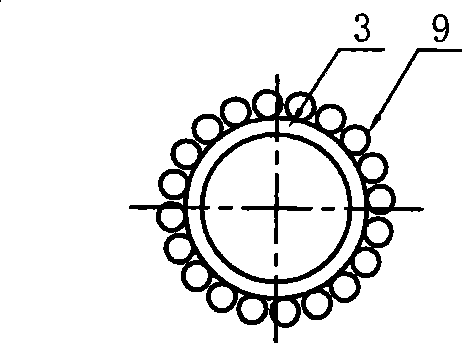

[0025] Lay a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com