Radiating module

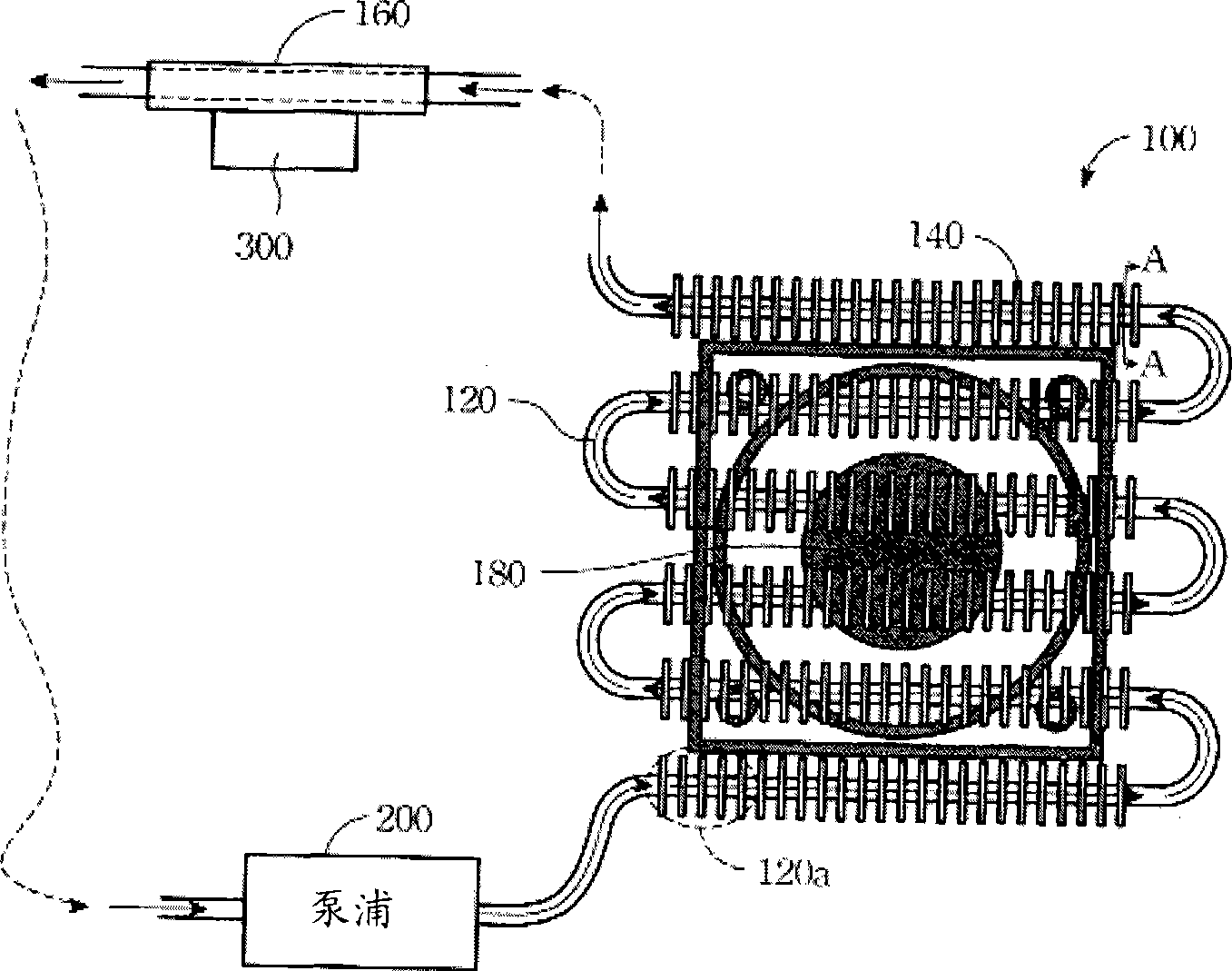

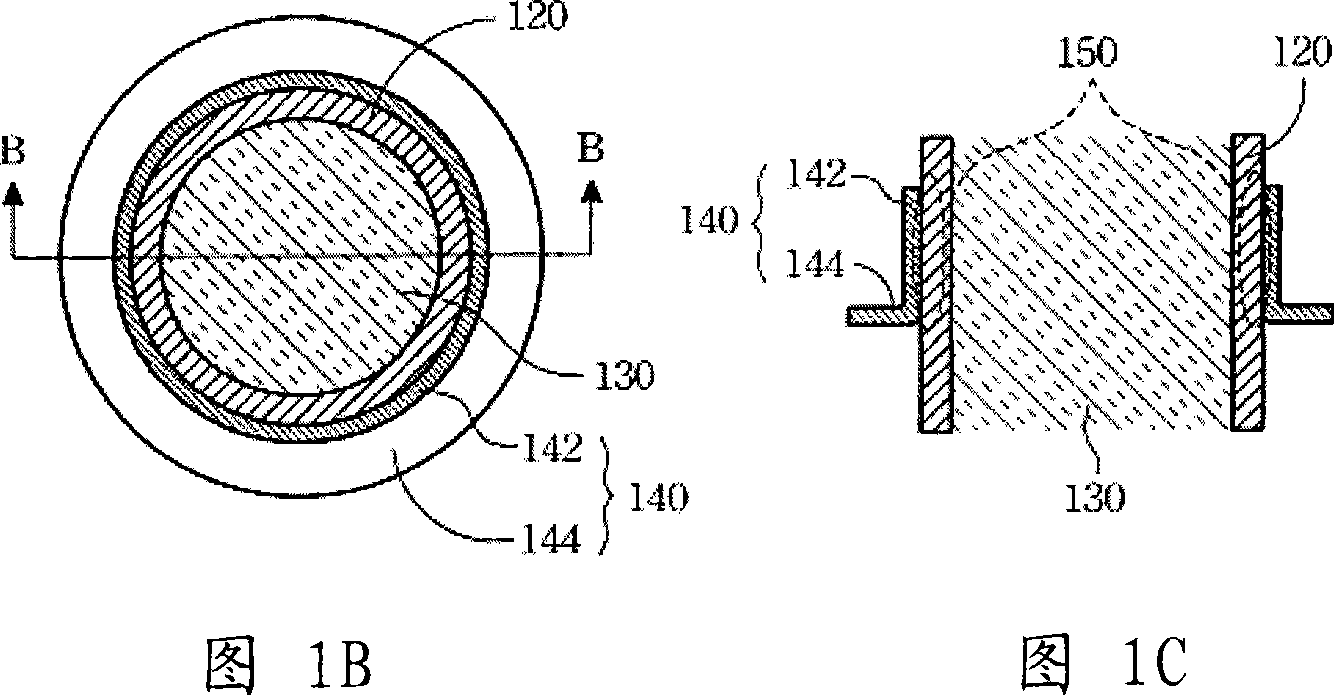

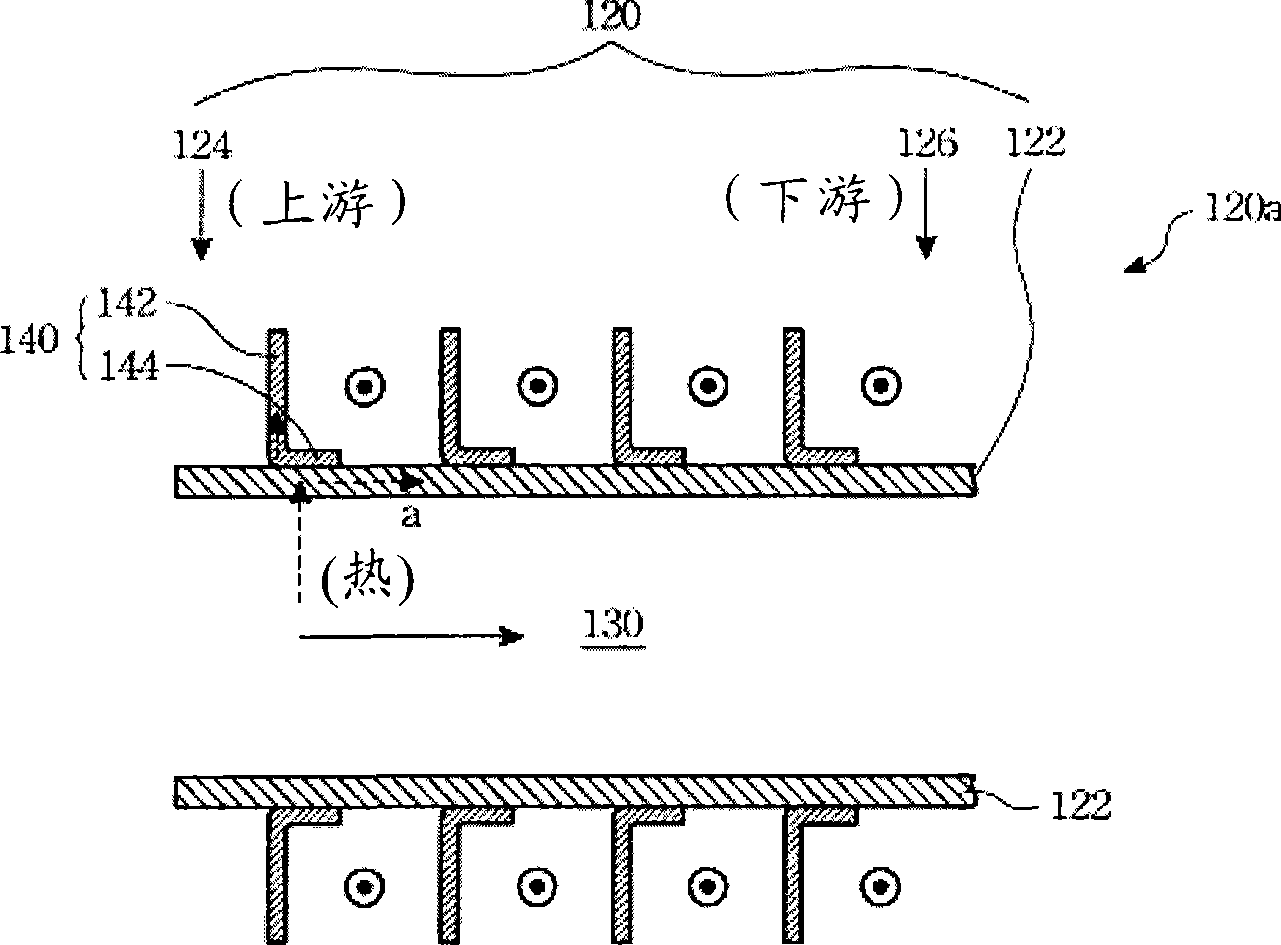

A technology of heat dissipation module and heat dissipation surface, which is applied in cooling/ventilation/heating renovation, instruments, electrical digital data processing, etc., can solve the problems of lowering, worsening heat transfer efficiency of heat sink 140, and raising the water temperature of downstream end 126, etc. Achieve light weight, improve heat dissipation efficiency, and reduce material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions attached to the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

[0065] Please refer to Figure 2A, the cooling module 400 is used for cooling a microprocessor (microprocessor) 500, such as a central processing unit (CPU) of a computer. The heat dissipation module 400 includes a base 420 , a duct 440 , a plurality of heat conducting fins 460 and a fan 480 . The base 420 is installed on the microprocessor 500 . The guide tube 440 has an opening (not shown) and a heat-insulating tube wall 442, the opening is connected to the base 420, the guide tube 440 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com