Frequency-doubling method capable of preventing frequency-doubling recede transition and laser

A frequency-doubling laser and frequency-doubling light technology are applied in the field of lasers to achieve the effects of improving frequency-doubling conversion efficiency, preventing frequency-doubling deconversion, and improving frequency-doubling conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

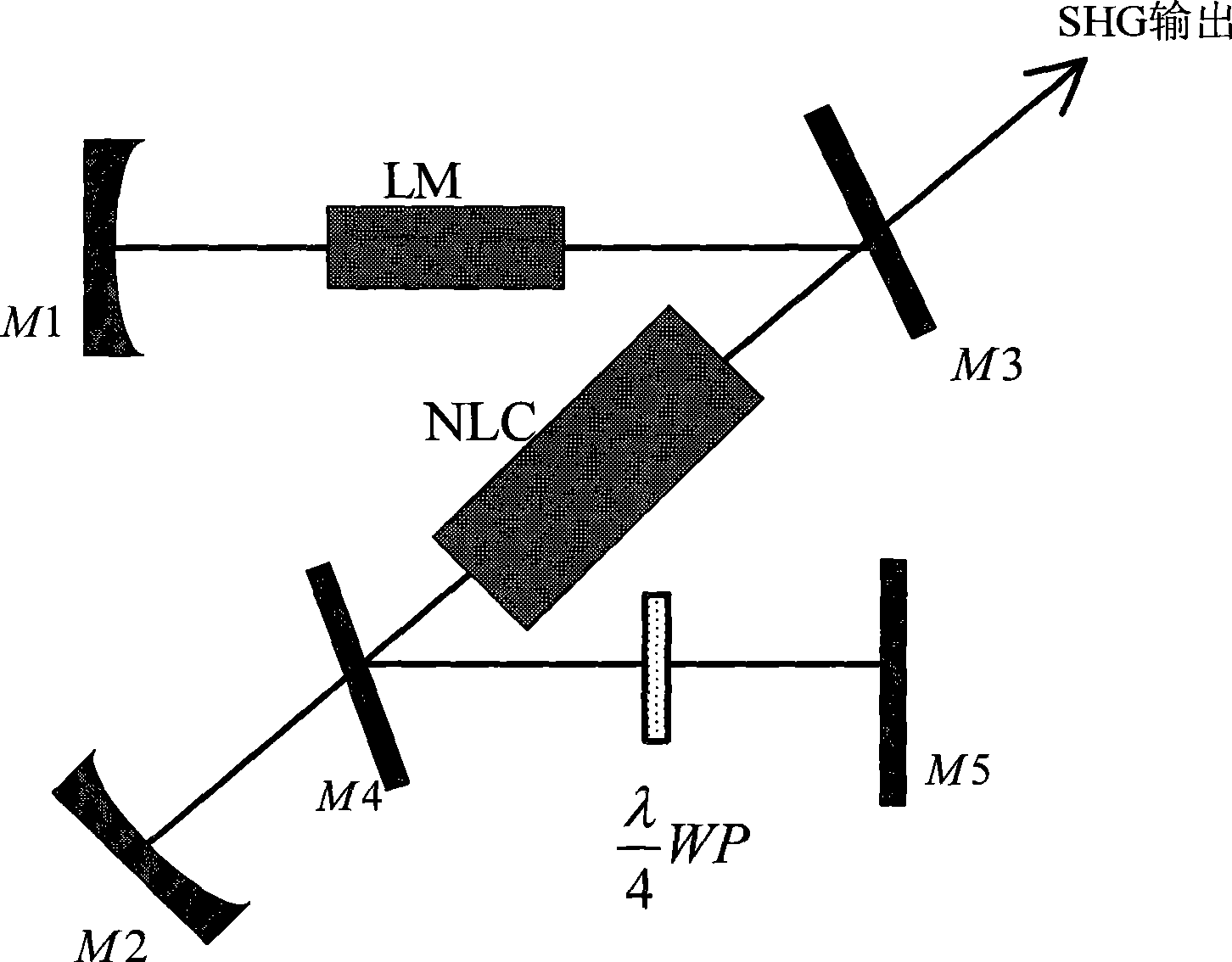

[0020] Such as figure 1 As shown, this embodiment adopts the type I phase-matched internal cavity frequency doubling. LM is Nd:YAG laser material, NLC is LBO frequency doubling material cut according to type I phase matching angle, WP is 1 / 4 wave plate of 532nm frequency doubling light, cavity mirrors M1 and M2 are highly reflective to 1064nm fundamental frequency light, The dichroic mirror M3 is highly reflective to 1064nm fundamental frequency light and highly transparent to 532nm frequency doubled light, the dichroic mirror M4 is highly transparent to 1064nm and highly reflective to 532nm, and the mirror M5 is highly reflective to 532nm.

[0021] The laser generated by Nd:YAG is in the "P" polarization state. After frequency doubling by LBO, a 532nm laser in the "S" polarization state is generated. After the frequency doubled light is reflected by the dichroic mirror M4, it passes through the 1 / 4 wave plate WP back and forth. The polarization direction is rotated by 90 deg...

Embodiment 2

[0023] This embodiment adopts the type II phase-matching internal cavity frequency doubling. LM is Nd:YV04 laser material, NLC is KTP frequency doubling material cut according to type II phase matching angle, WP is 1 / 4 wave plate of 532nm frequency doubling light, cavity mirrors M1 and M2 are highly reflective to 1064nm fundamental frequency light, The dichroic mirror M3 is highly reflective to 1064nm fundamental frequency light and highly transparent to 532nm frequency doubled light, the dichroic mirror M4 is highly transparent to 1064nm and highly reflective to 532nm, and the mirror M5 is highly reflective to 532nm.

[0024] The polarization direction of the laser generated by Nd:YV04 is at an angle of 45 degrees to the paper surface. After frequency doubling by KTP, a 532nm laser with "S" polarization is generated. The frequency doubling light is reflected by the dichroic mirror M4 and passes through 1 / 4 wave back and forth. For sheet WP, the polarization direction is rotat...

Embodiment 3

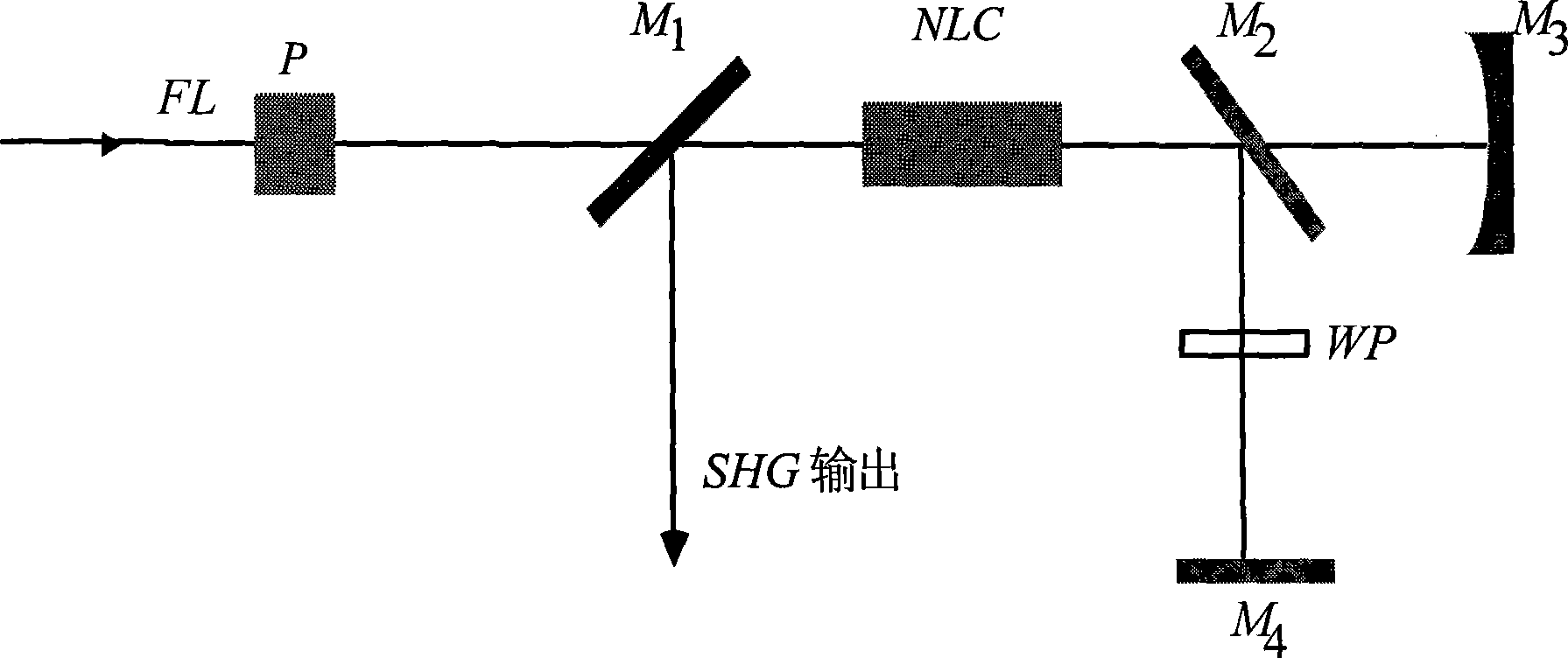

[0025] Embodiment 3: as figure 2 As shown, this embodiment adopts type I phase-matching external cavity frequency doubling. FL is the fundamental frequency light, P is the optical isolator, NLC is the LBO frequency doubling material cut according to the type I phase matching angle, WP is the 1 / 4 wave plate of the 532nm frequency doubling light, dichroic mirrors M1 and M2 are for 1064nm High transmission of fundamental frequency light, high reflection of 532nm frequency doubled light, mirror M3 high reflection of 1064nm fundamental frequency light, and reflector M4 high reflection of 532nm frequency doubled light.

[0026] The FL fundamental frequency light passing through the optical isolator P is in the "P" polarization state, and after being frequency-doubled by LBO, a 532nm laser in the "S" polarization state is generated. After the frequency-doubled light is reflected by the dichroic mirror M2, it passes through 1 / 4 back and forth With the wave plate WP, the polarization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com