Method and apparatus for controlling the flow of molten steel in a mould

一种控制结晶、钢水的技术,应用在用于控制结晶器中的钢水流动和装置领域,能够解决结晶器扰流、喷嘴流动冲突等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

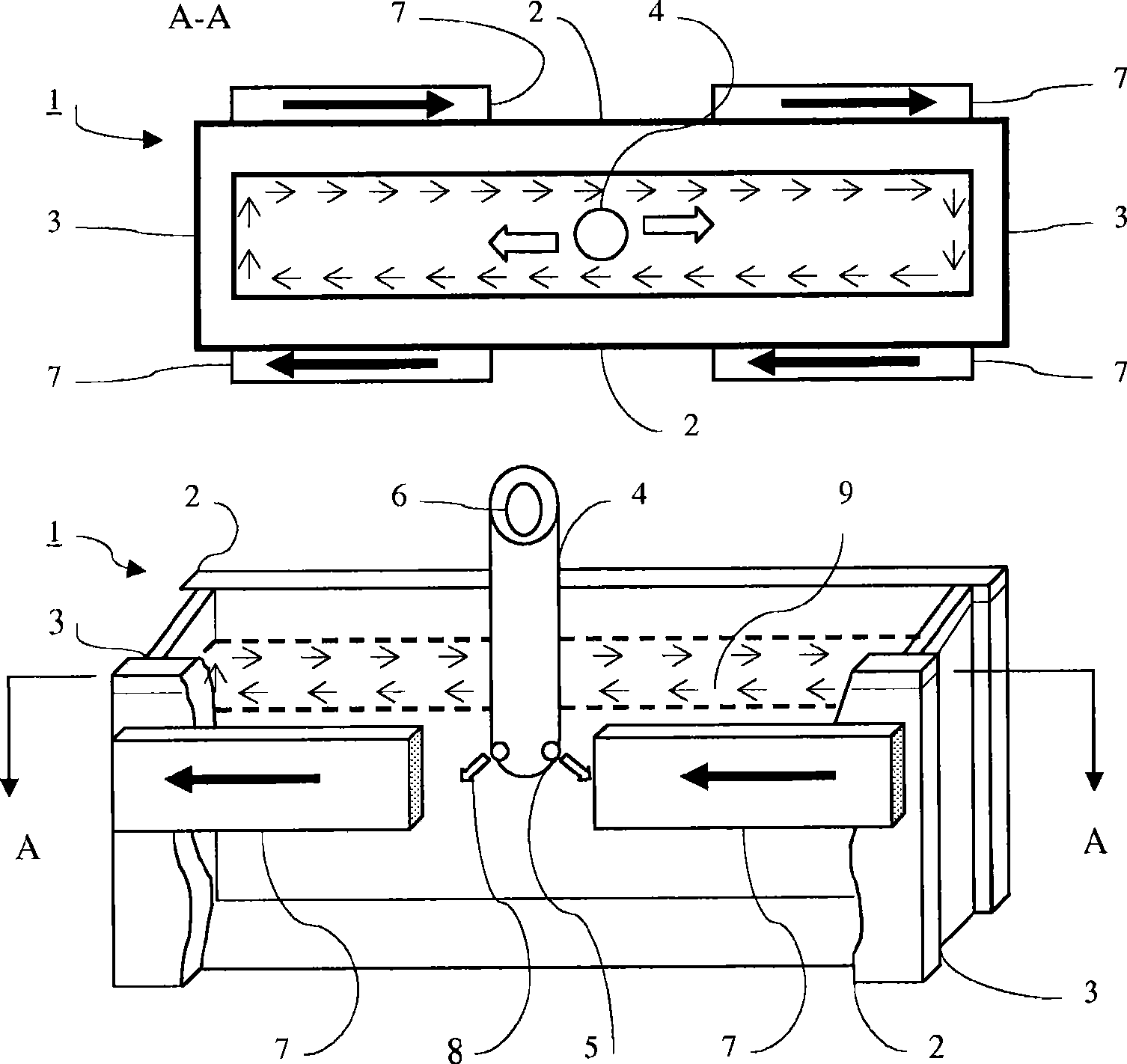

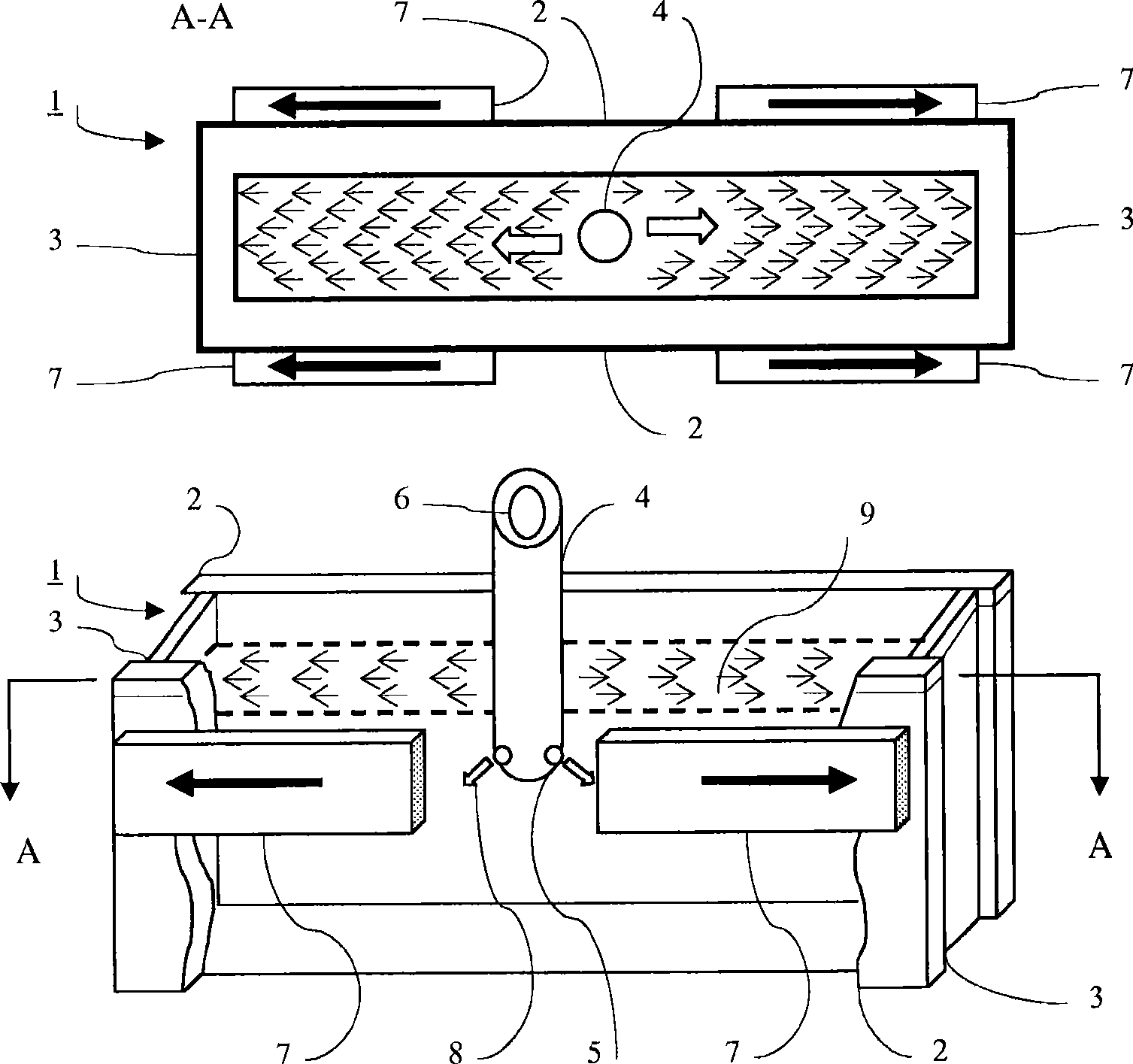

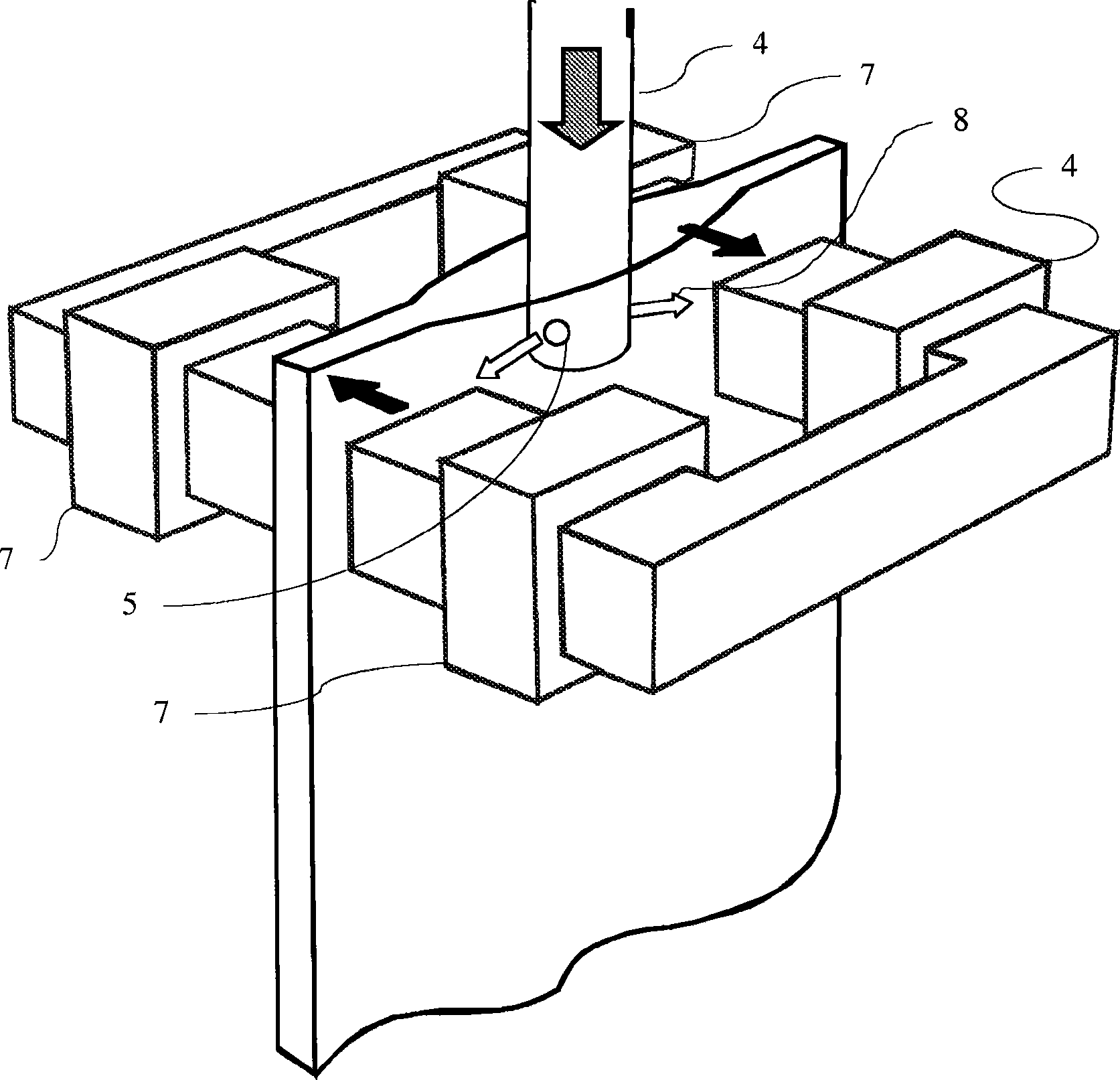

[0023] Embodiments of the present invention are described below with reference to the accompanying drawings. figure 1 and figure 2 Respectively are the schematic diagrams of the slab continuous casting machine used when implementing the present invention. More specifically, figure 1 and figure 2 Both are schematic perspective / front views of parts of a crystallizer according to the invention.

[0024] refer to figure 1 and figure 2 , a tundish (not shown) is provided at a predetermined position above the crystallizer 1, the crystallizer 1 has crystallizer long sides 2 facing each other and mutually opposing crystallizer long sides 2 arranged inwardly between the crystallizer long sides 2 Short side of the crystallizer 3. A submerged nozzle 4 is provided in contact with the bottom surface of a slide nozzle (not shown) connected to the tundish, and has a pair of discharge ports 5 at its lower portion. A molten steel outflow port 6 is formed for allowing molten steel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com