Method for extracting lipid from naked oats

A technology for extracting oil and naked oats, applied in edible oil/fat, food preparation, food science, etc., can solve the problems of high cost, small extraction amount, high equipment requirements, etc., to improve efficiency, reduce extraction cost, and reduce extraction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

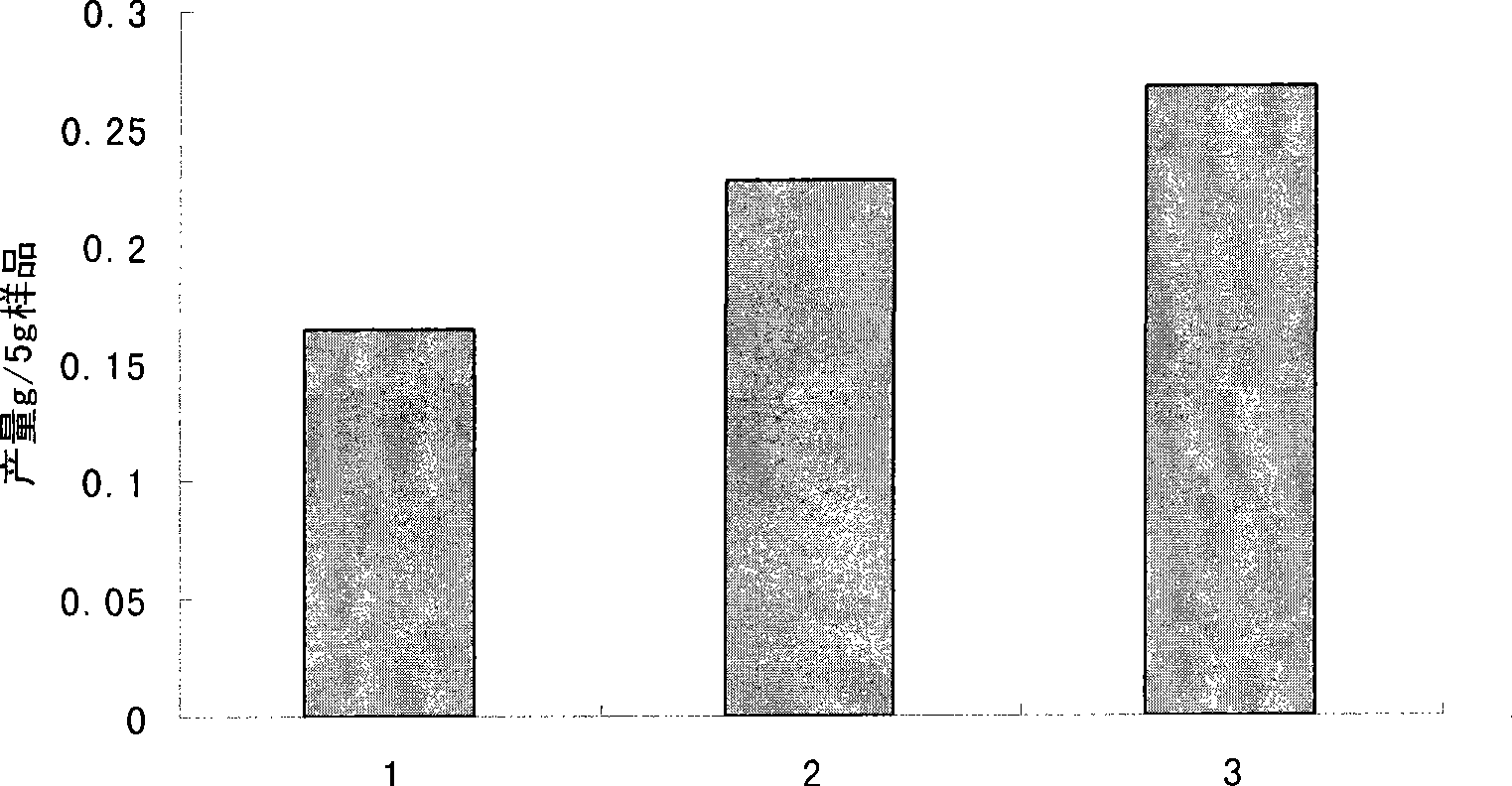

[0013] Example 1

[0014] (1) Extract oil from naked oats

[0015] Pass the dry naked oat powder through a 60-mesh sieve, accurately weigh 5.0134g and place it in a 50ml ground-mouth Erlenmeyer flask, take 3 parallel samples, add 25ml ethyl acetate respectively, and ultrasonically extract at 15°C for 1h. The extract was centrifuged in a refrigerated high-speed centrifuge at 8000r / min at 17°C for 30min, the supernatant was passed through a 0.45μm filter membrane, and the extract was combined in a rotary evaporator to recover the solvent under reduced pressure to obtain the oil extracted from naked oats. The electronic balance is weighed, and the average weight of the sample is 0.1862g.

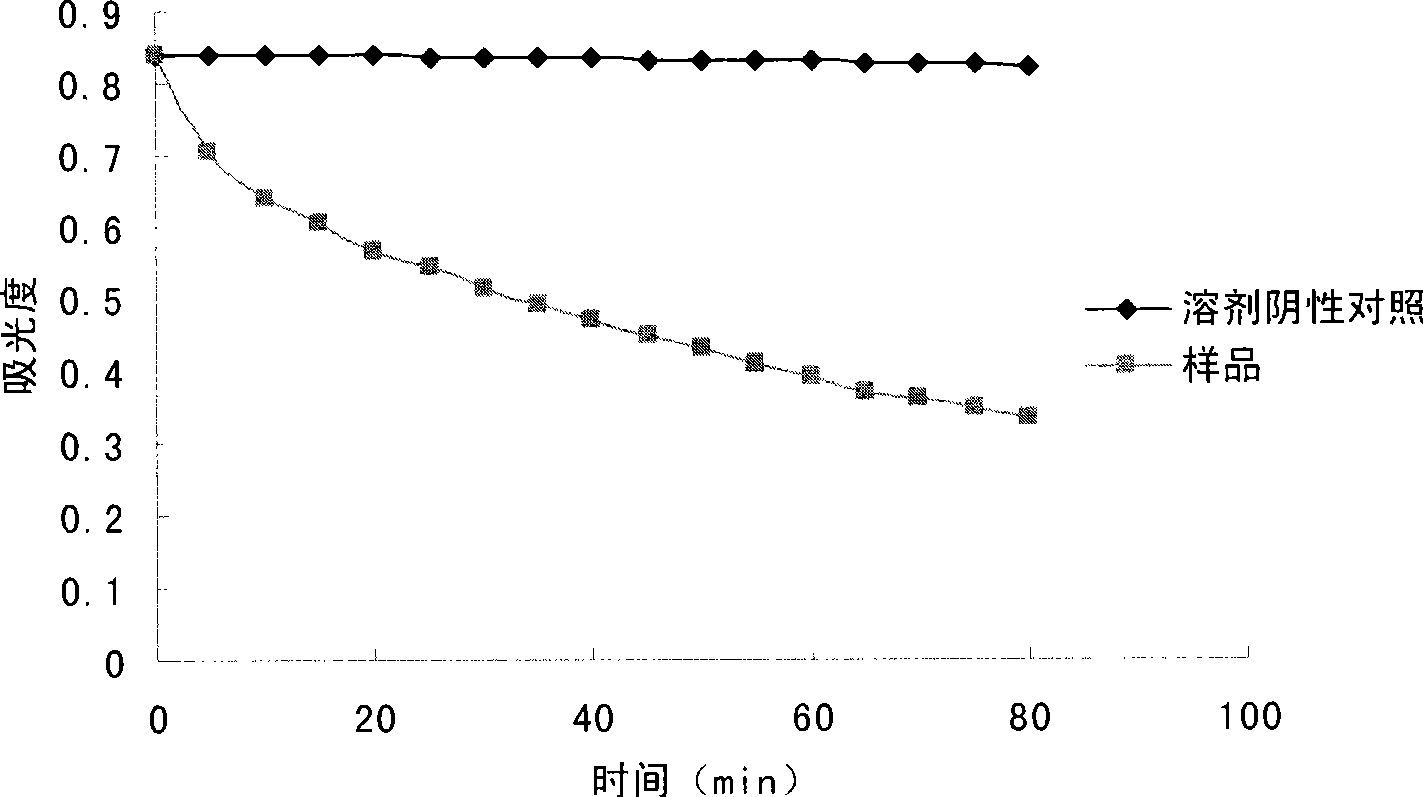

[0016] (2) Sample detection

[0017] The electronic balance accurately weighs 0.1 g of the oily compounds extracted from naked oats, and dissolves them in 1 ml of mixed solvent (n-hexane (v): ethyl acetate (v): methanol (v) = 1:2:3) solution to obtain 0.1g / ml mixed solution of oil and fat compounds...

Example Embodiment

[0018] Example 2

[0019] (1) Extract oil from naked oats

[0020] The dried naked oat sample was processed into powder, passed through a 60-mesh sieve, accurately weighed 5.0214g and placed in a 50ml ground-mouthed Erlenmeyer flask, took 3 parallel samples, added 50ml ethyl acetate, and performed ultrasonic extraction at 25°C for 2h. The extract was centrifuged in a refrigerated high-speed centrifuge at 6000 r / min at 20°C for 40 min, the supernatant was passed through a 0.45 μm filter membrane, and the extract was combined in a rotary evaporator to recover the solvent under reduced pressure to obtain the oil extracted from naked oats. The electronic balance is weighed, and the average weight of the sample is 0.2278g.

[0021] (2) Sample detection

[0022] The electronic balance accurately weighs 0.1 g of the oily compounds extracted from naked oats, and dissolves them in 1 ml of mixed solvent (n-hexane (v): ethyl acetate (v): methanol (v) = 1: 1: 3) solution to obtain 0.1g / ml mix...

Example Embodiment

[0023] Example 3

[0024] (1) Extract oil from naked oats

[0025] The dried naked oat sample was processed into powder, passed through a 60-mesh sieve, accurately weighed 5.0179g and placed in a 50ml ground-necked Erlenmeyer flask, took 3 parallel samples, added 25ml n-hexane, and extracted with ultrasonic at 25°C for 1h. The extract was centrifuged in a refrigerated high-speed centrifuge at 10000 r / min at 17°C for 30 min, the supernatant was passed through a 0.45 μm filter membrane, and the extract was combined in a rotary evaporator to recover the solvent under reduced pressure to obtain the oil extracted from naked oats. Weigh on an electronic balance, and the average weight of the sample is 0.2588g.

[0026] (2) Sample detection

[0027] The electronic balance accurately weighs 0.1 g of the oily compounds extracted from naked oats, and dissolves them in 1 ml of mixed solvent (n-hexane (v): ethyl acetate (v): methanol (v) = 1: 1: 3) solution to obtain 0.1g / ml mixed solution of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap