Polylactic acid/functional graphene composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid/functionalized graphene composite material and its preparation, can solve the problems of insufficient elongation at break, poor compatibility, high brittleness of polylactic acid, etc., and achieve excellent thermal properties and mechanical properties, compatibility and wettability, and the effect of increasing interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

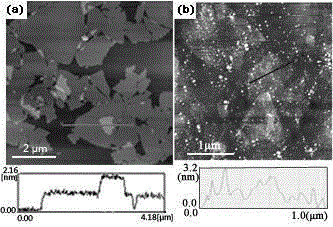

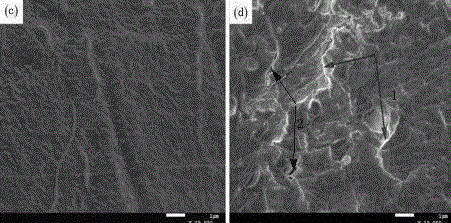

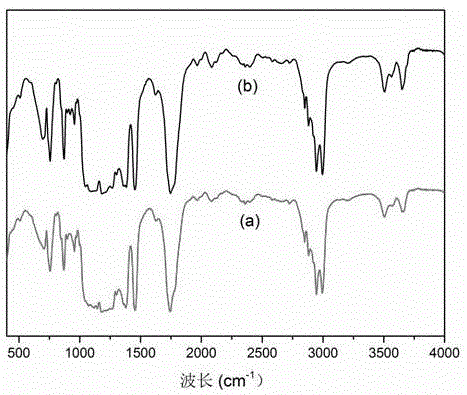

Image

Examples

Embodiment 1

[0034] A polylactic acid / functionalized graphene composite material is prepared from graphene oxide, polylactic acid and didodecyldimethylammonium bromide, wherein the mass fraction of graphene oxide in the composite material is 0.1 %, and the mass ratio of graphene oxide to didodecyldimethylammonium bromide is 1.2:1.

[0035] The preparation method of this composite material comprises the following steps:

[0036] a) Take 240ml of graphene oxide aqueous solution with a concentration of 2mg / ml, add NaOH to adjust its pH to 9, and then add 80ml of dodecyldimethylammonium bromide with a concentration of 5mg / ml to obtain functionalized graphene Precipitate; then add 300ml trichloromethane wherein, after stirring for 10min, functionalized graphene can be seen to redisperse in the organic phase trichloromethane, after standing for stratification, take off the lower layer solution with separating funnel, obtain functionalized graphite Chloroform dispersion of alkenes;

[0037] b) ...

Embodiment 2

[0040] A polylactic acid / functionalized graphene composite material is prepared from graphene oxide, polylactic acid and didodecyldimethylammonium bromide, wherein the mass fraction of graphene oxide in the composite material is 0.2 %, and the mass ratio of graphene oxide to didodecyldimethylammonium bromide is 1.2:1.

[0041] The preparation method of this composite material comprises the following steps:

[0042]a) Take 720ml of graphene oxide aqueous solution with a concentration of 1mg / ml, add NaOH to adjust its pH to 9, and then add 120ml of dodecyldimethylammonium bromide with a concentration of 5mg / ml to obtain functionalized graphene Precipitate; then add 600ml dichloromethane wherein, after stirring for 10min, functionalized graphene can be seen to redisperse in the organic phase dichloromethane, after standing for stratification, take off the lower layer solution with separating funnel, obtain functionalized graphite Dichloromethane dispersion of alkenes;

[0043] ...

Embodiment 3

[0046] A polylactic acid / functionalized graphene composite material is prepared from graphene oxide, polylactic acid and didodecyldimethylammonium bromide, wherein the mass fraction of graphene oxide in the composite material is 0.3 %, and the mass ratio of graphene oxide to didodecyldimethylammonium bromide is 1.2:1.

[0047] The preparation method of this composite material comprises the following steps:

[0048] a) Take 240ml of graphene oxide aqueous solution with a concentration of 3mg / ml, add NaOH to adjust its pH to 9, and then add 120ml of dodecyldimethylammonium bromide with a concentration of 5mg / ml to obtain functionalized graphene Precipitate; then add 300ml trichloromethane wherein, after stirring for 10min, functionalized graphene can be seen to redisperse in the organic phase trichloromethane, after standing for stratification, take off the lower layer solution with separating funnel, obtain functionalized graphite Chloroform dispersion of alkenes;

[0049] b)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com