Mud scraper for sewage precipitation pool

A sludge scraper and sedimentation tank technology, applied in the directions of sedimentation separation, sedimentation tank, chemical instruments and methods, etc., can solve the problems of not being suitable for sewage sedimentation tanks, affecting sludge sedimentation, occupying large space, etc., and reducing The number of reciprocating operations, the effect of solving the dead angle of sludge and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

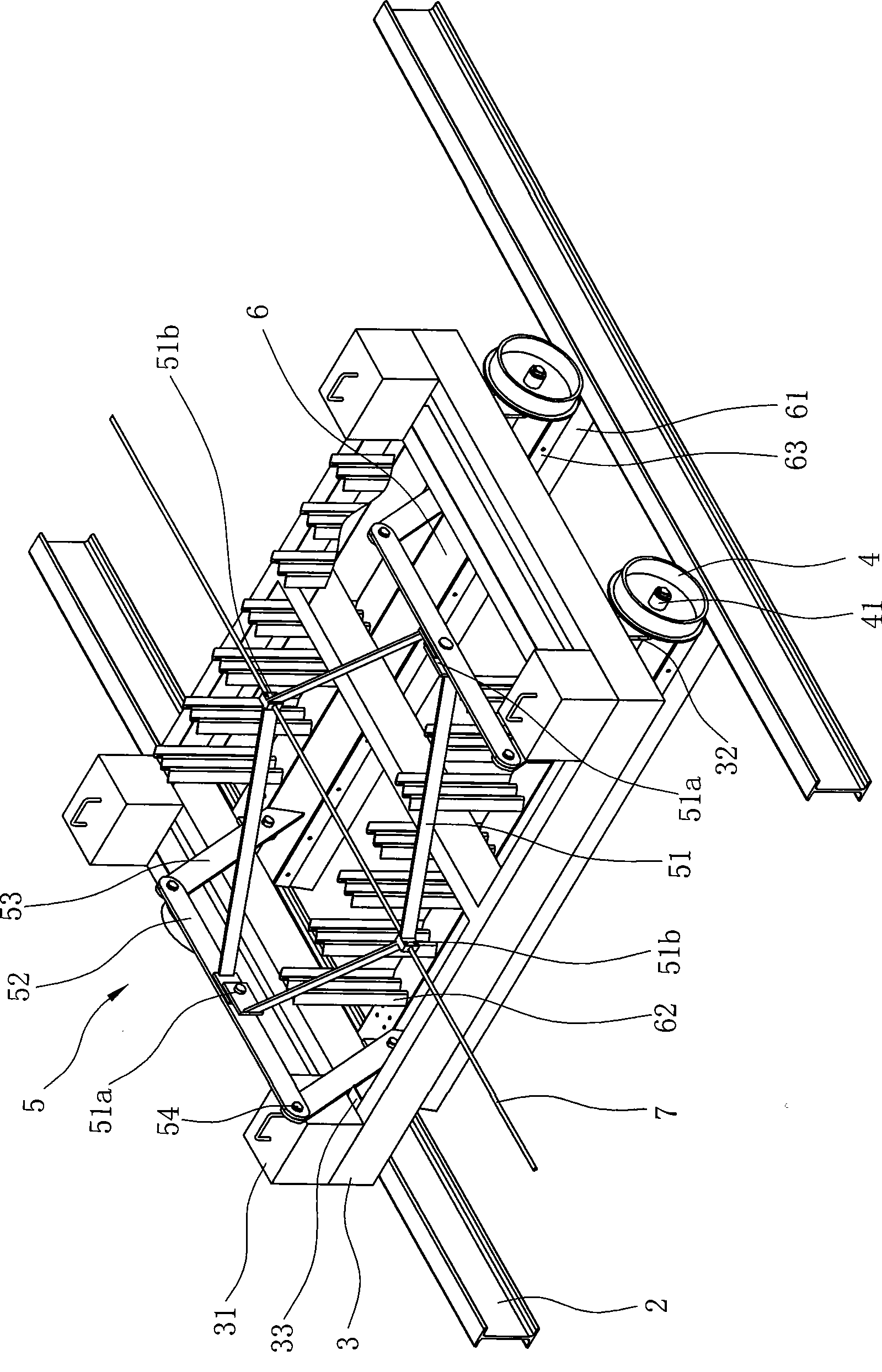

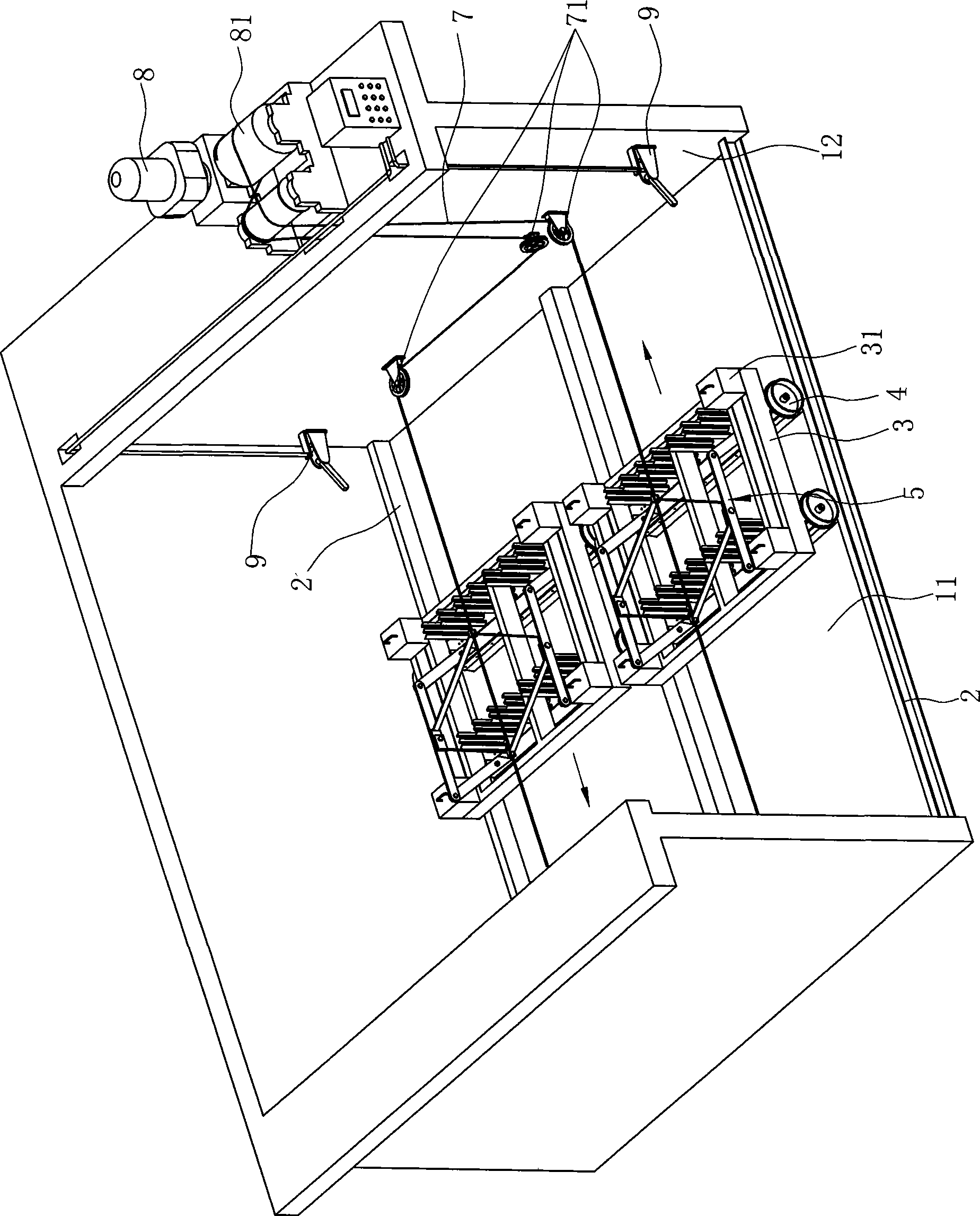

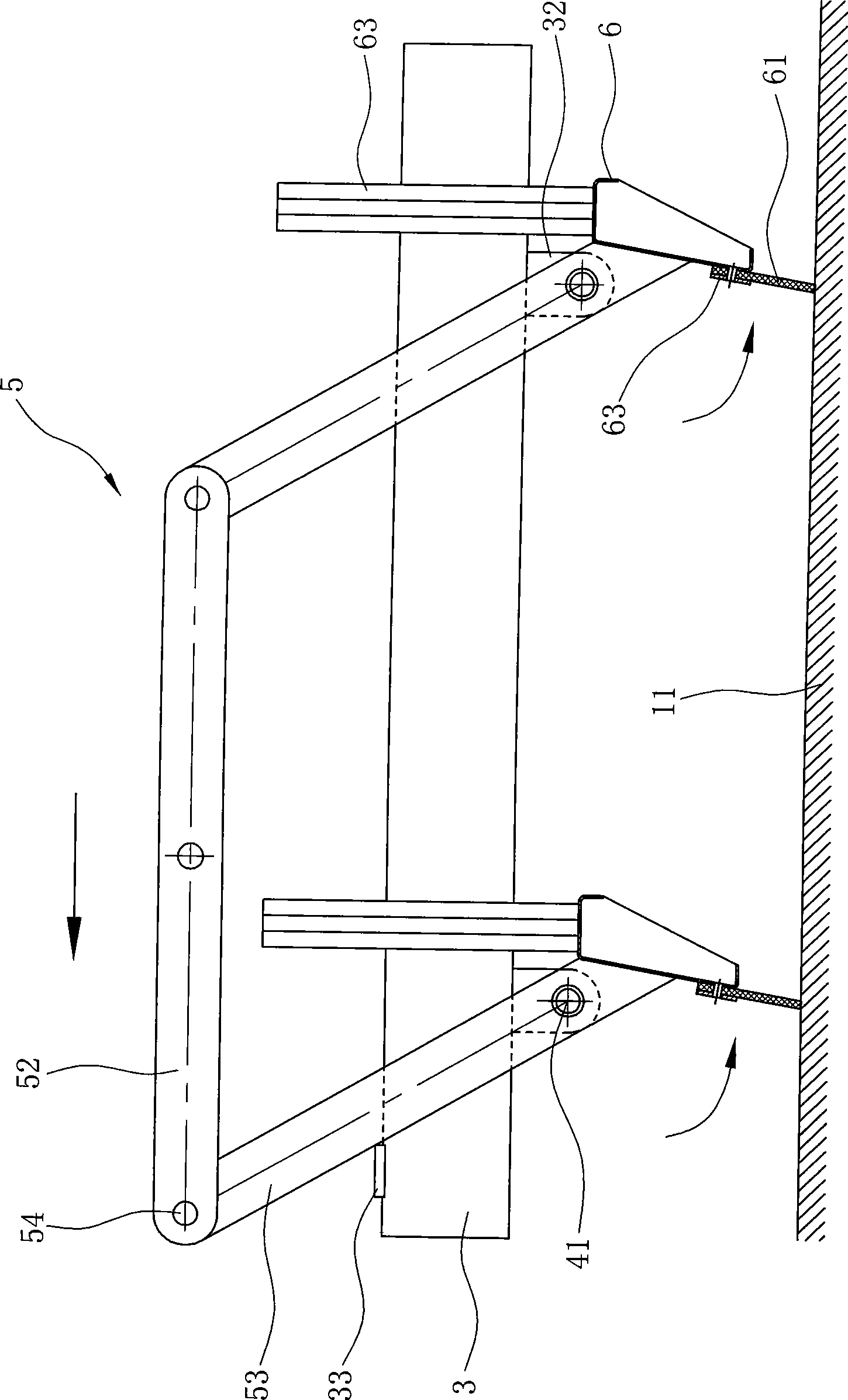

[0033] like Figure 1 ~ Figure 4 As shown, the mud scraper used in the sewage sedimentation tank includes a track 2 arranged at the bottom of the pool 11, a frame 3 that can walk freely on the track 2, four wheels 4 located under the frame 3, and a Link mechanism 5, mud scraper 6 and a rope 7 on the vehicle frame 3;

[0034] Wherein, the vehicle frame 3 is a rectangular frame with an outer periphery, and a weight block 31 is respectively arranged on the top of its four corners, so that the mud scraper can walk more smoothly at the bottom 11 of the pool, and the bottom of the vehicle frame 3 is located on the four sides. Each corner is provided with a support plate 32, and each wheel 4 is rotatably positioned on the outside of the corresponding support plate 32 through the wheel shaft 41 passing through the corresponding support plate 32, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com