Modular injection molding machines and their collections

A technology of injection molding machines and modules, which is applied in the collection field composed of injection molding machines and multiple injection molding machines, can solve problems such as waste and idle injection molding machines, and achieve the effects of improving machine utilization, reducing quantity, and reducing equipment idleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

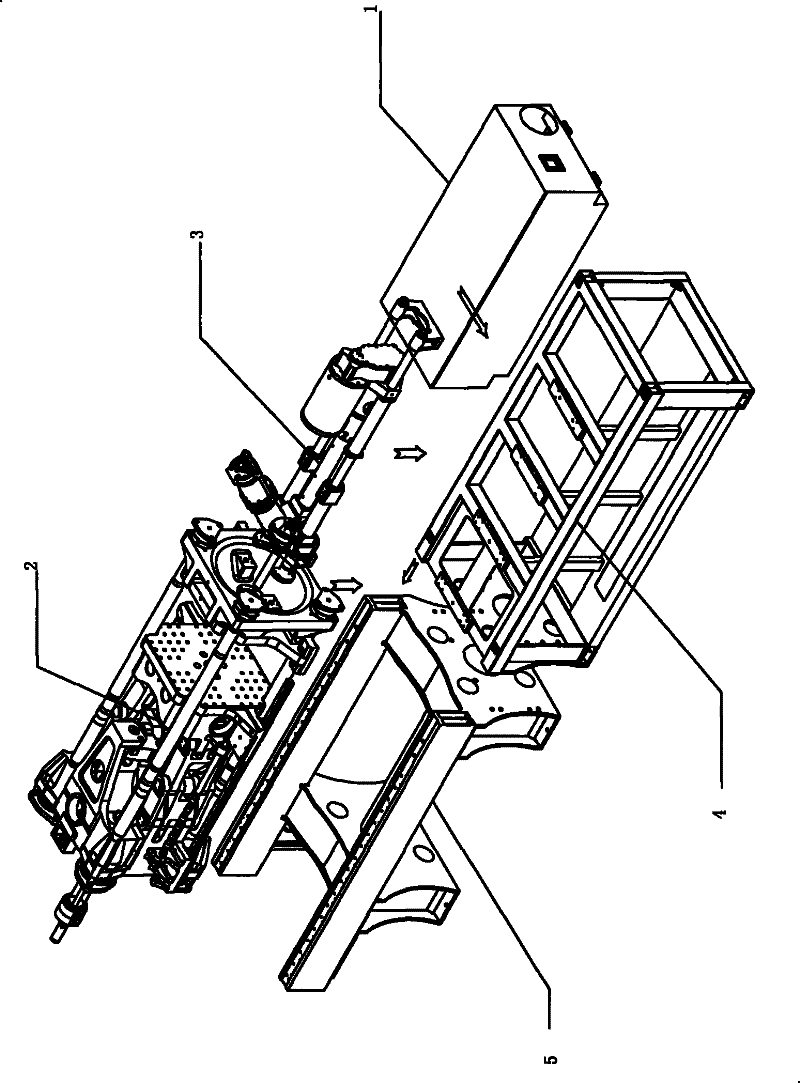

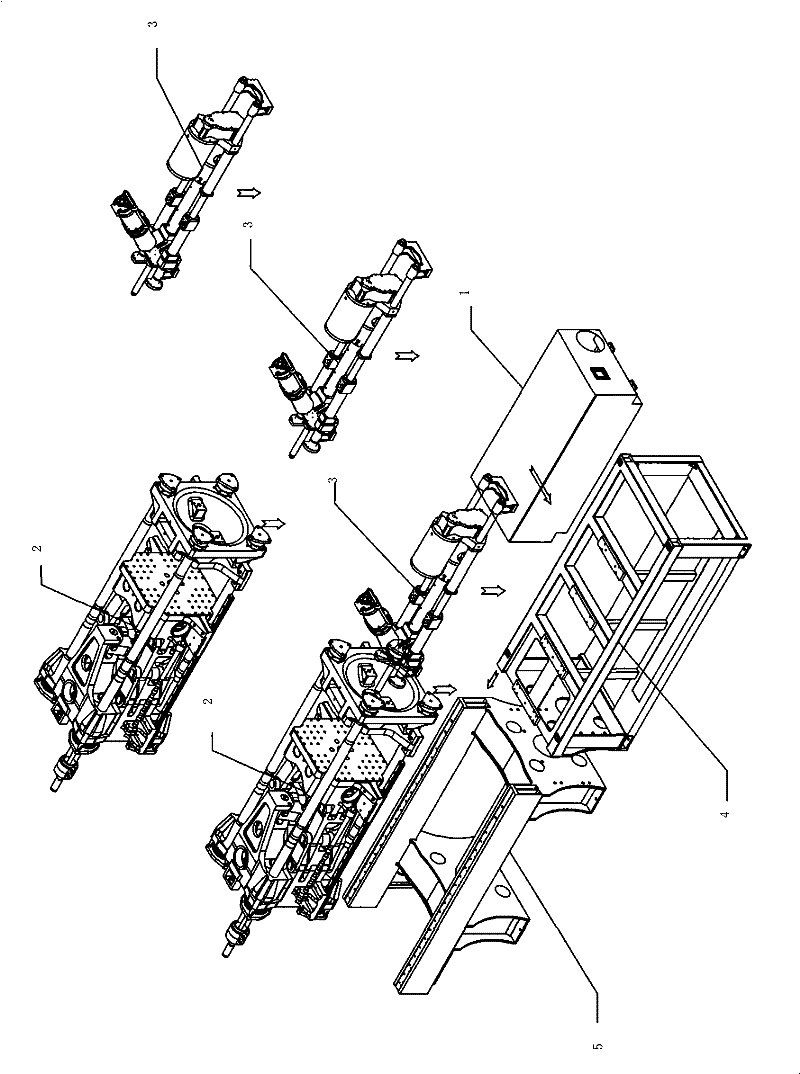

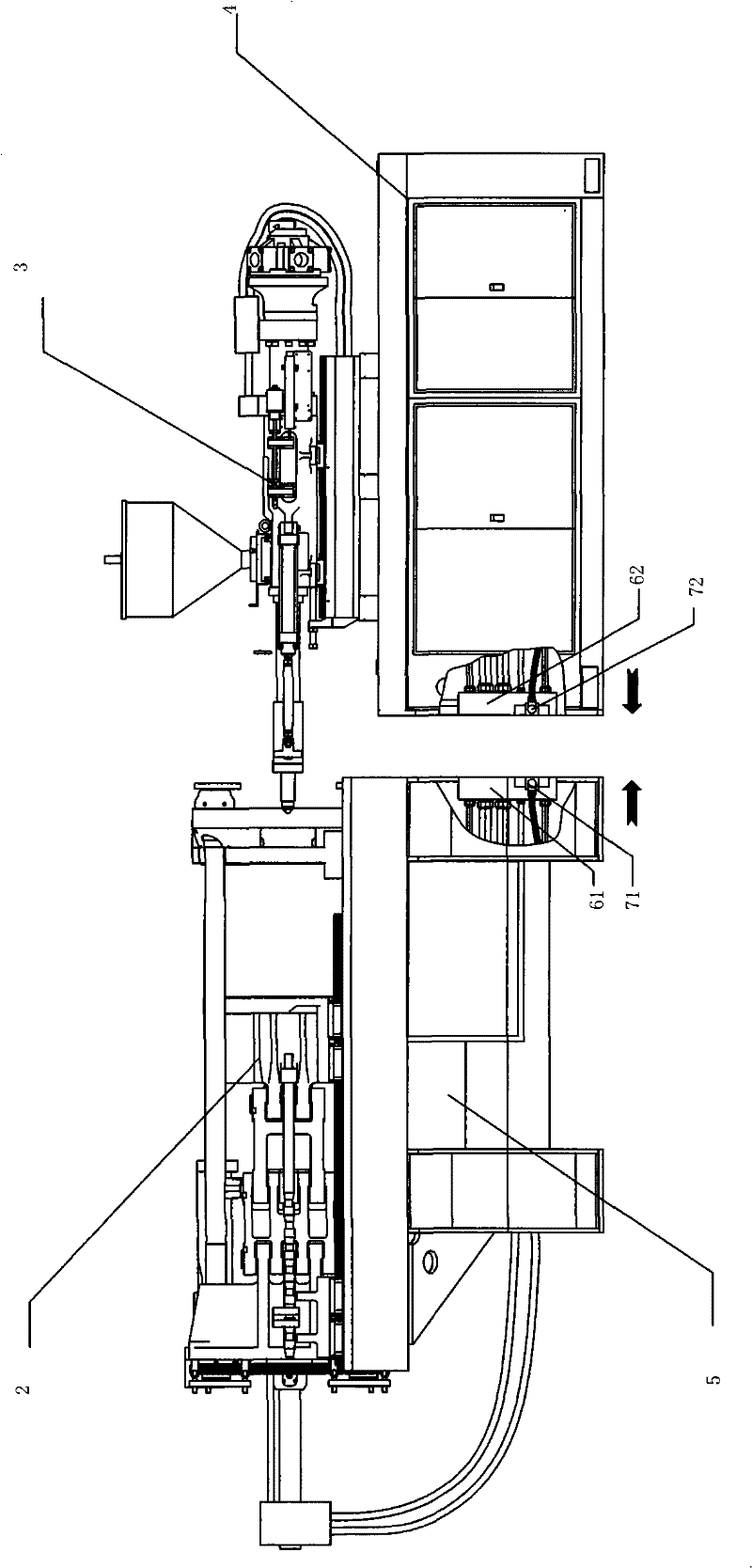

[0034] refer to figure 1 , 2 , 3, 4:

[0035] The modular injection molding machine includes a power module 1 that can be assembled interchangeably, a clamping module 2 that closes and locks the mold, and an injection module 3. The power module 1 includes a pump, an oil tank, and an electric control cabinet. The injection module 2 includes a screw barrel and a heating device, and the clamping module 2 includes a mold clamping mechanism, a mold adjustment mechanism and a locking mechanism; the screw barrel can be formed with the injection module 3 A sub-module group for quick assembly of other parts; the interface between the modules adopts a quick joint, and the injection frame 4 of the injection module 3 is independent of the mold clamping frame 5 of the mold clamping module 2 Set, and set the adjustment mechanism that makes the center height alignment of the mold clamping frame 5 and the injection frame 4.

[0036] The fixed car wall 8 of the clamping module is horizontal...

Embodiment 2

[0043] refer to figure 1 , 2 , 3, 4

[0044] According to the set of modular injection molding machines described in the present invention, the corresponding modules of each of the modular injection molding machines have the same interface, so as to achieve the interchangeability of the corresponding modules among the injection molding machines.

[0045]Users can flexibly assemble various modules to form injection molding machines suitable for specific situations according to the requirements of specific products on the plasticizing ability and mold clamping ability of the injection molding machine. Therefore, when the existing injection molding machines are not enough, manufacturers often do not need to buy new injection molding machines, but can make full use of the modules of idle injection molding machines for assembly. Therefore, the present invention is particularly advantageous for manufacturers with multiple injection molding machines. In this way, in terms of overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com