Rapid stabilizing method for thermal state massive steel slag

A technology of stabilization treatment and steel slag, which is applied in the direction of recycling technology, etc., to achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

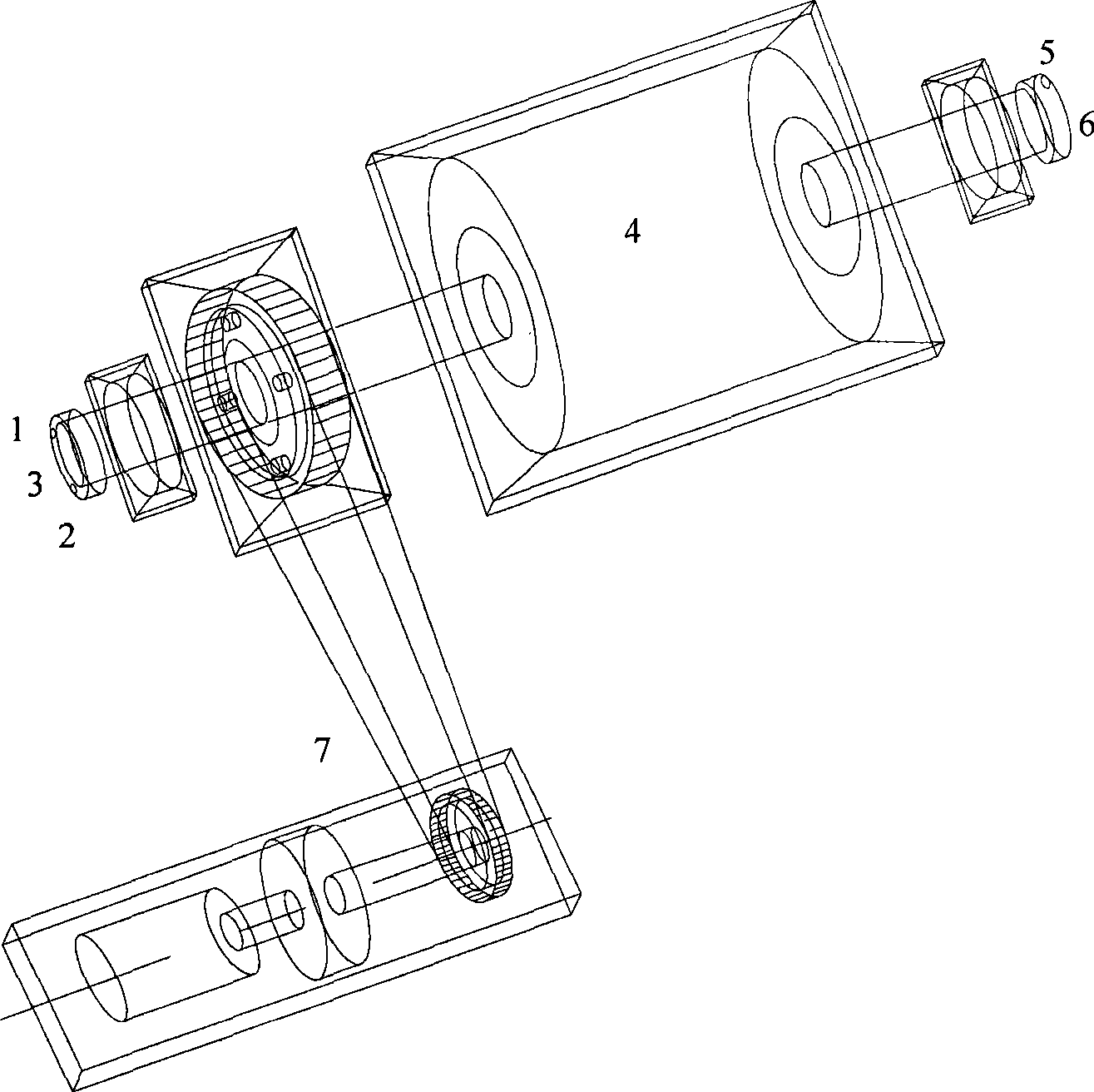

[0020] The invention relates to a rapid stabilization treatment method for hot massive steel slag, which realizes the combination of steps figure 1 Described as follows:

[0021] The steel slag discharged from the slag tank, the hot solid steel slag after preliminary cooling and granulation, enters the rotating solid steel slag rapid stabilization treatment device 4 through the slag inlet 3, and the CO 2 Gas and water vapor pass through CO 2 The air inlet 1 and the water vapor inlet 2 enter the steel slag rapid stabilization treatment device 4, and the stabilization treatment device driven by the driving device 7 is in the process of rotation, through the interaction between the steel slag itself or the steel slag and the grinding medium, to realize the steel slag At the same time of granulation, the CaCO generated during the stabilization process and wrapped on the surface of unreacted f-CaO and f-MgO particles 3 and MgCO 3 The hard shell is destroyed, and the unreacted f-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com