Butt joint method of thin-wall metal pipe

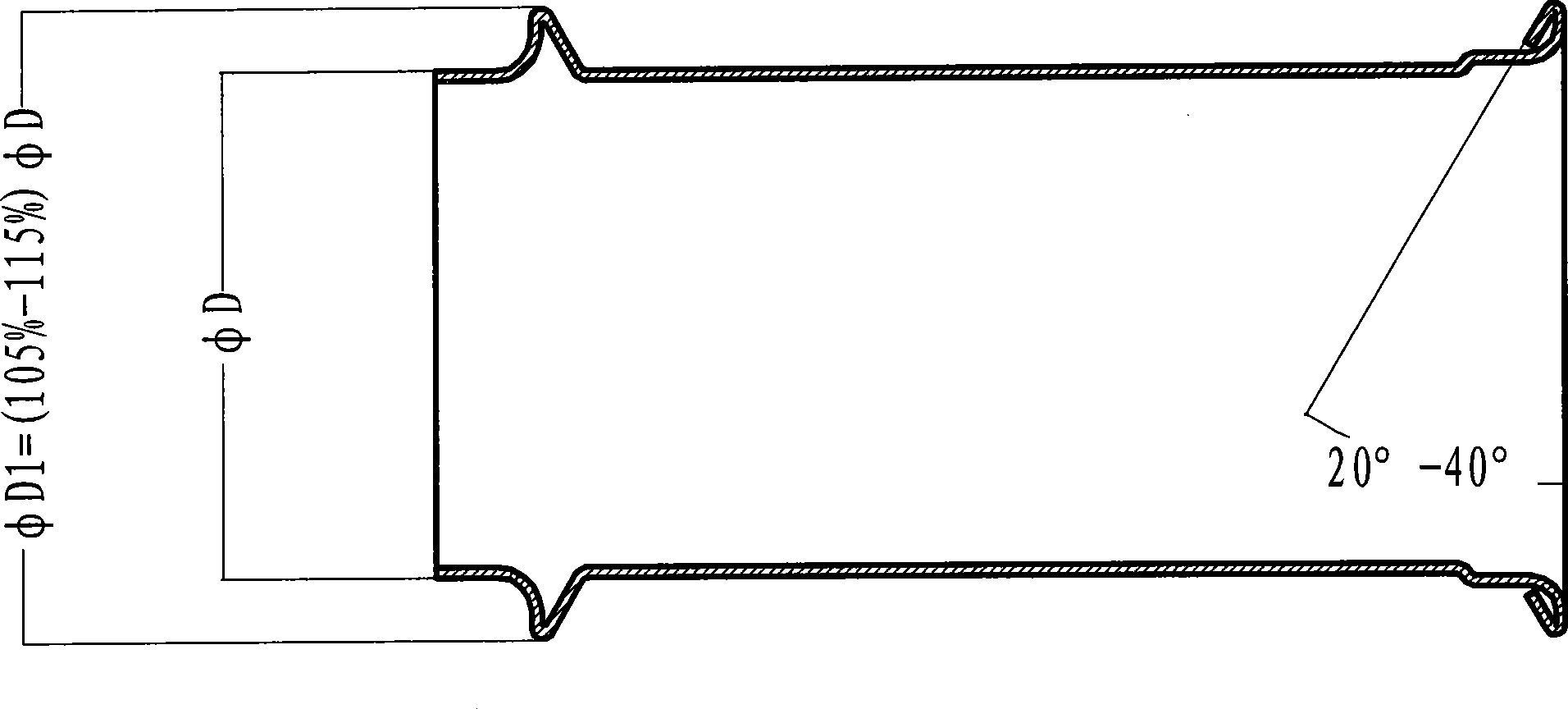

A technology for metal thin-walled pipes, which is applied in the direction of pipes/pipe joints/fittings, sockets/socket connections, passing components, etc., which can solve the problem of no adjustment allowance for metal thin-walled pipes, shortened service life of pipe fittings, and insufficient tensile strength and other problems, to achieve the effects of strong impact resistance, material saving, and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Embodiment (adopting an automobile smoke exhaust pipe that the method of the present invention is butted):

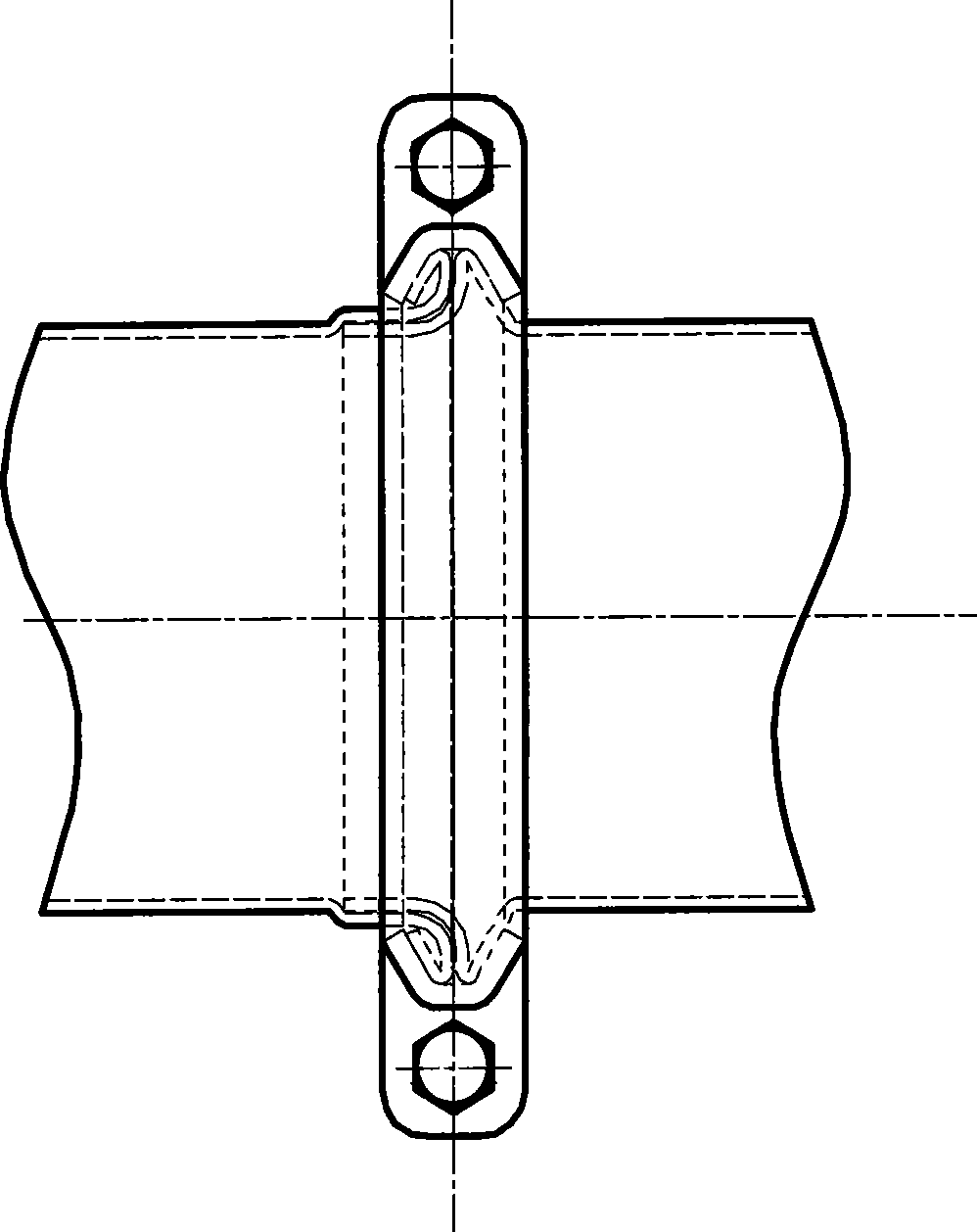

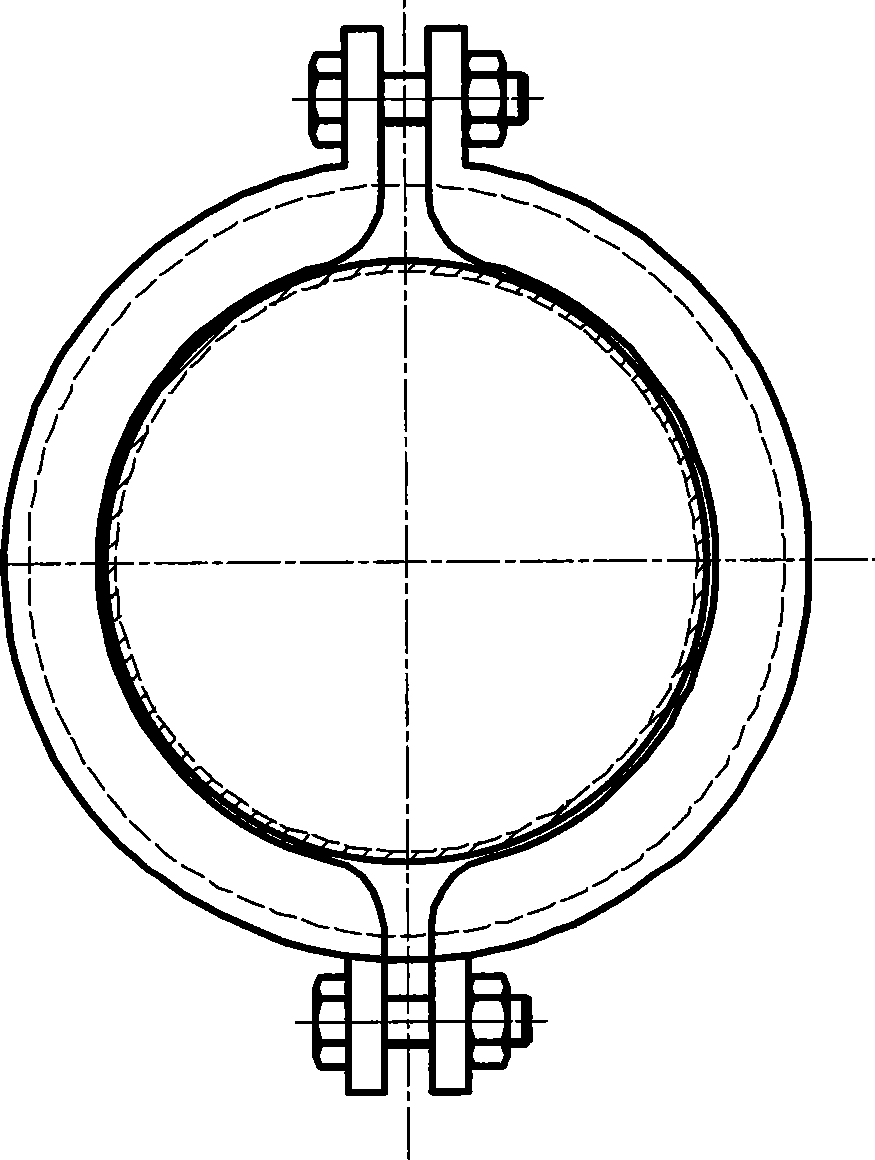

[0013] Such as Figure 4 The automobile smoke exhaust pipe shown is composed of parts one 1, metal thin-walled elbow one 2, metal thin-walled straight pipe two 3, metal thin-walled elbow three 4, metal thin-walled straight pipe four 5, metal thin-walled straight pipe five 6 , part two 7, hoop 8, bolt 9, nut 10, adopt the method of the present invention butt joint with bolt 9, nut 10, hoop 8, metal thin-walled elbow one 2, metal thin-walled straight pipe two 3, Metal thin-walled curved pipe three 4, metal thin-walled straight pipe four 5, metal thin-walled straight pipe five 6 are connected and fastened together, and then installed on part one 1 and part two 7. Since every two metal thin-walled tubes can be rotated 360°, the steel tube has a relatively large amount of adjustment, which can overcome the existing metal tubes that are prone to breakage, disjoint, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com