Method for measuring gas concentration by air-sensitive ultra-magnetostriction thin film

A giant magnetostrictive and thin-film technology, applied in the direction of using material absorption and weighing, etc., to achieve the effect of wide measurement range, high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

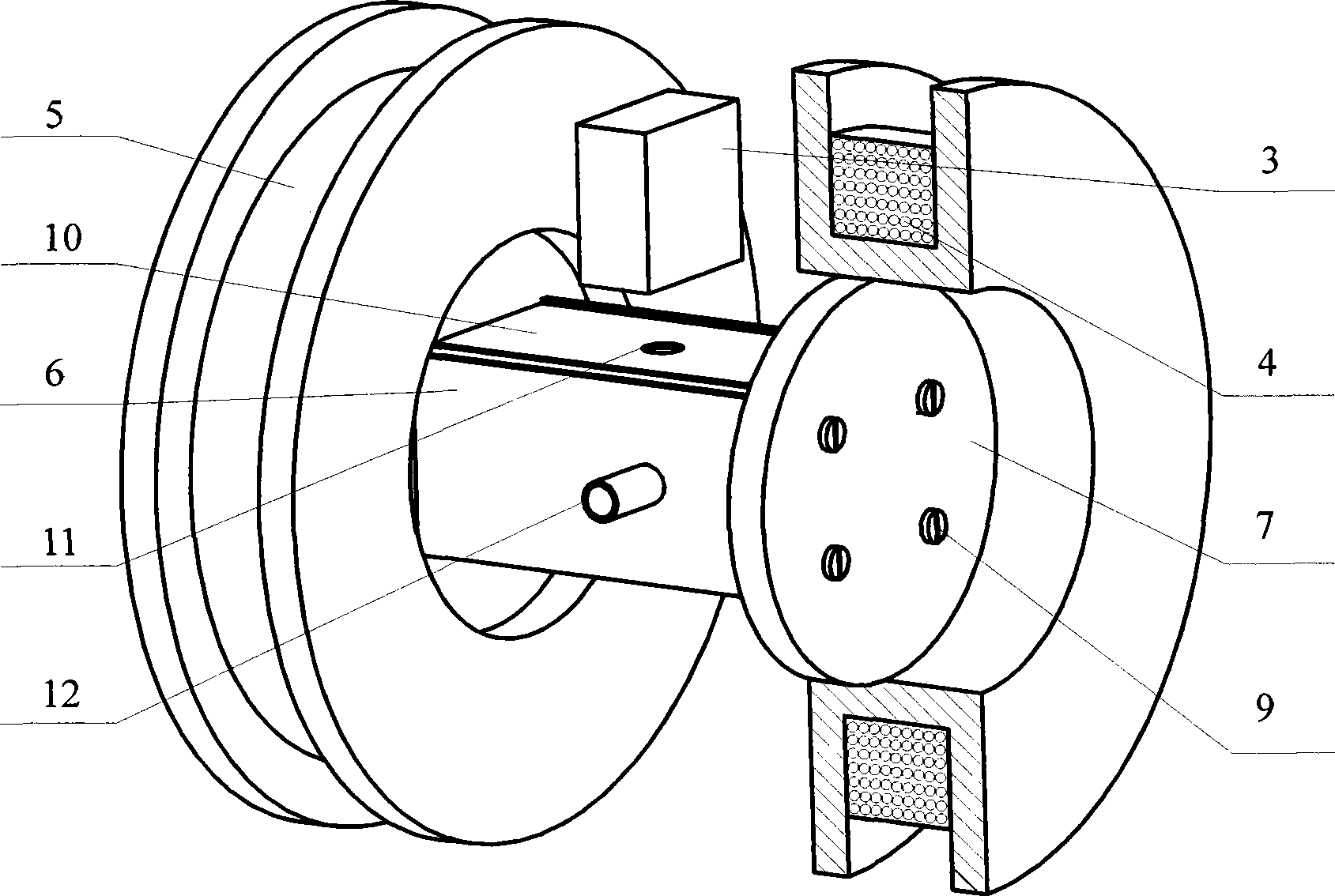

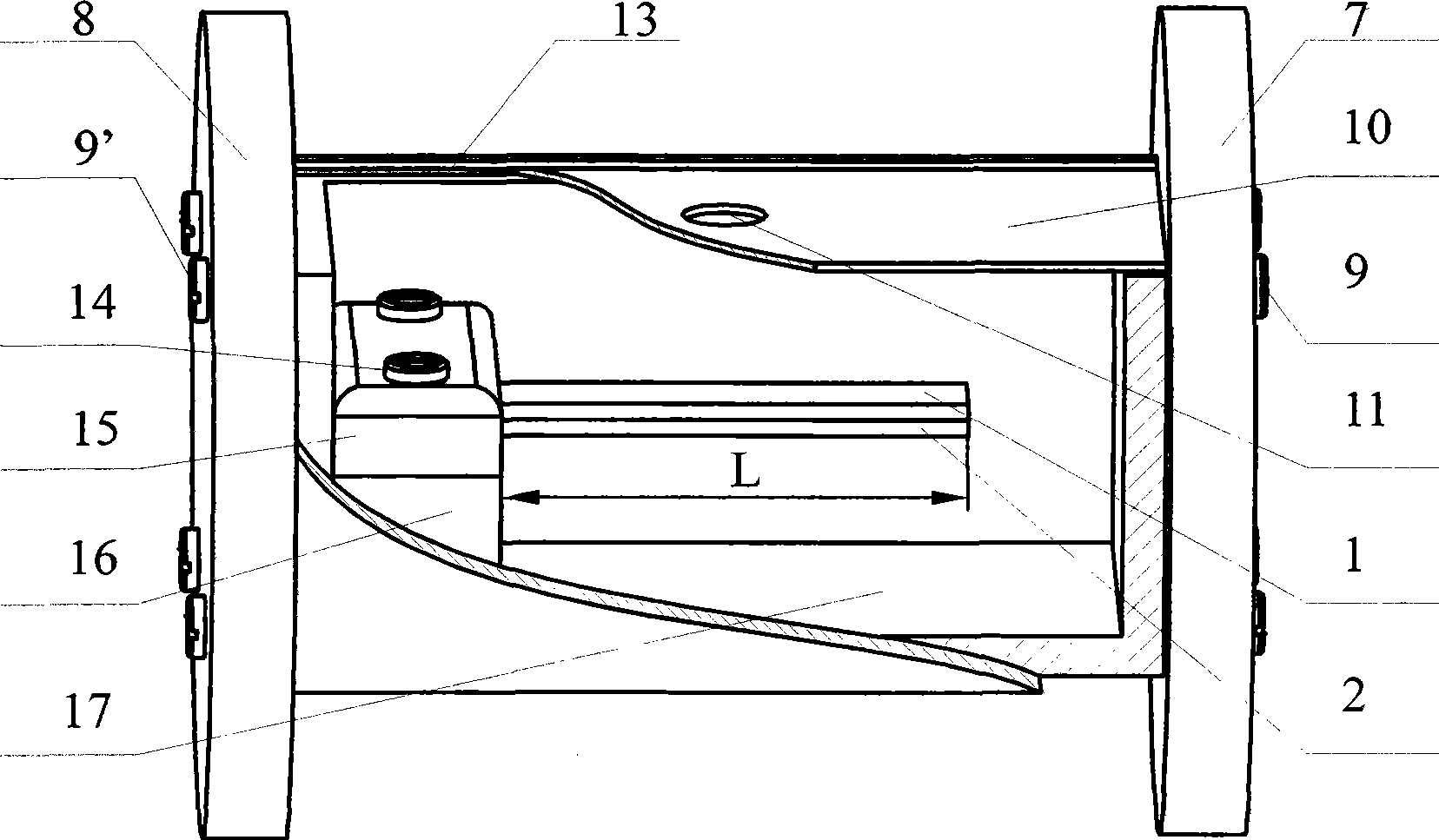

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. The basic principle of the present invention is: when the sensitive layer absorbs the gas to be detected, the mass M of the gas-sensitive giant magnetostrictive film will change slightly by Δm, so that The resonant frequency f also changes Δf correspondingly, and the relationship between the two is Δf=-fΔm / (2M), wherein, the size of Δm has a direct relationship with the concentration of the target gas to be detected, so the gas-sensitive supermagnetic The detection of the resonant frequency of the stretchable film is used to detect the gas concentration.

[0032] Apply gas concentration measurement method of the present invention to realize the measurement to acetic acid gas, concrete implementation process is as follows:

[0033] (1) Prepare polylysine and albumin solutions with a concentration of 10 mg / mL as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com