Data correction method used for varying data of chemical engineering flow system

A data correction and chemical process technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as difficult to accurately estimate significant errors, complex data correction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below with reference to the accompanying drawings of the present invention.

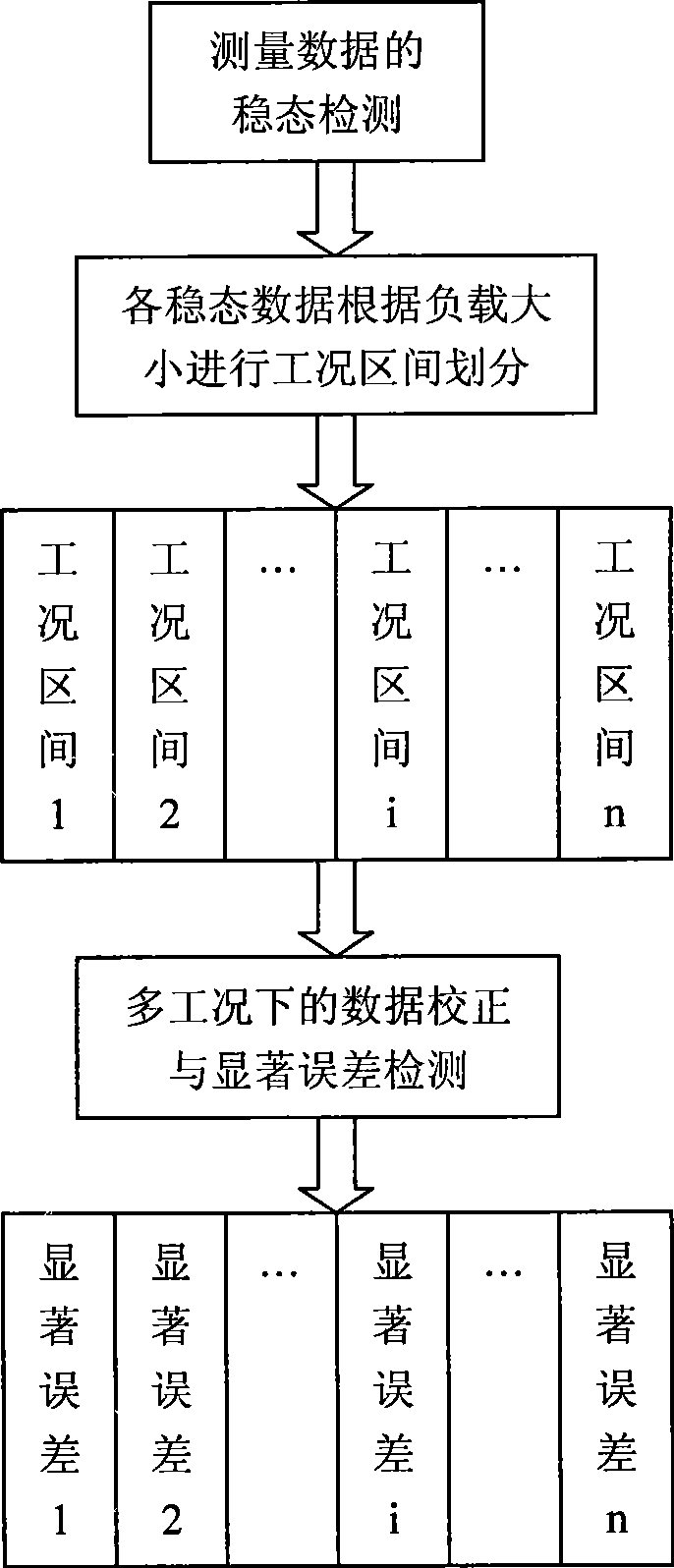

[0028] figure 1 It is a schematic diagram of the data correction method under the variable load of the chemical process system. Such as figure 1 As shown, the method mainly includes steady-state detection of measurement data, division of steady-state working condition intervals, data correction and significant error detection under multiple working conditions. The process is to first make a steady-state judgment based on several key measurement bit numbers, divide the average value of these steady-state data into the steady-state working condition interval according to the size of the load, and divide it into a number of different steady-state working condition intervals. Number correction and significant error detection are performed on multi-variable and multiple sets of measurement data in each steady-state working condition interval,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com