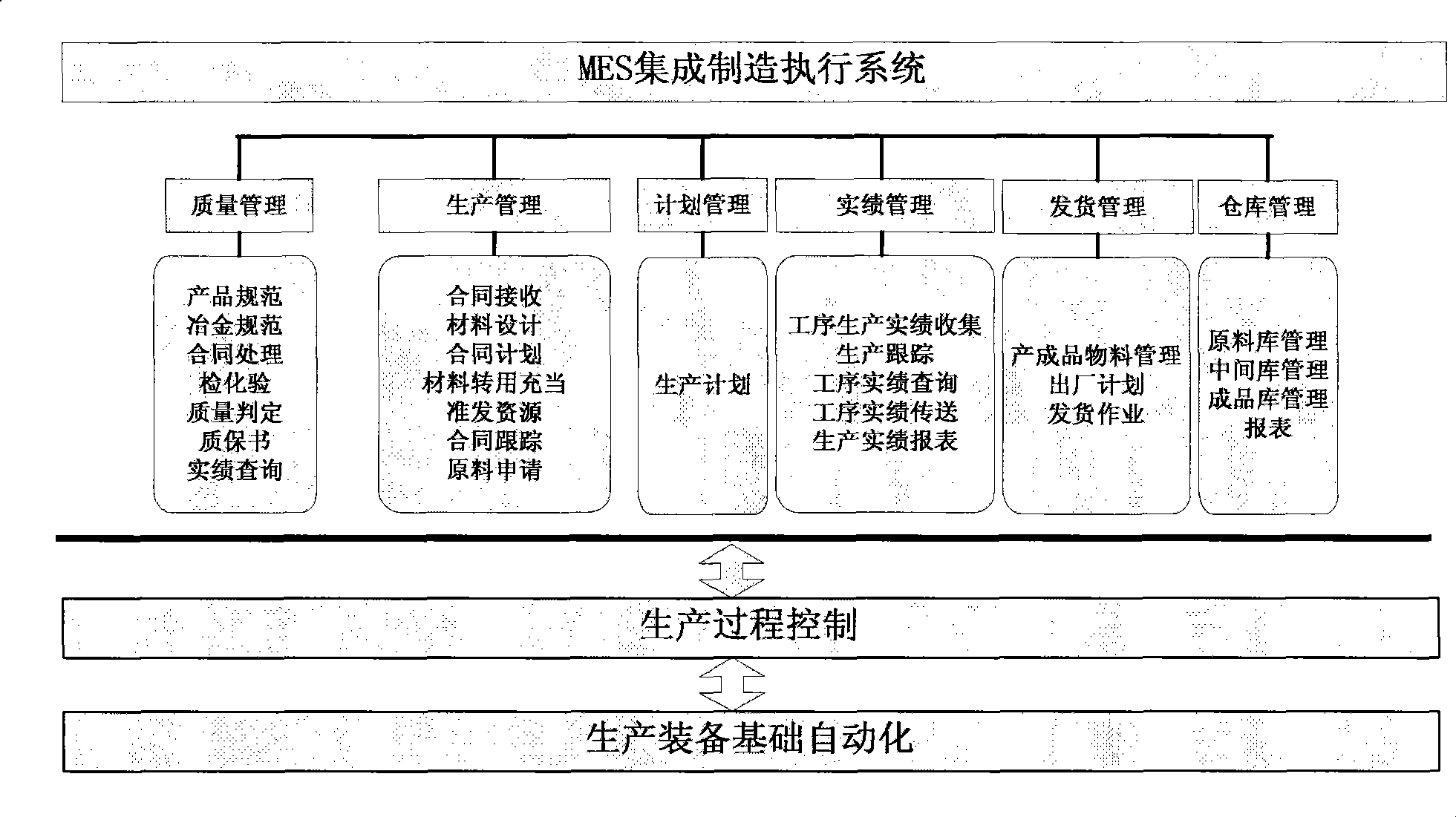

Layered MES software system architecture

A software system and management system technology, applied in the field of layered MES software system architecture, can solve problems such as the inability to smoothly and easily realize the expansion of system functions, the inability to realize flexible real-time tracking of contracts, and the inability to flexibly realize dynamic scheduling of contracts, etc. , to achieve the effect of shortening the product production cycle, reducing the average comprehensive production cost, and improving the efficiency of production organization and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

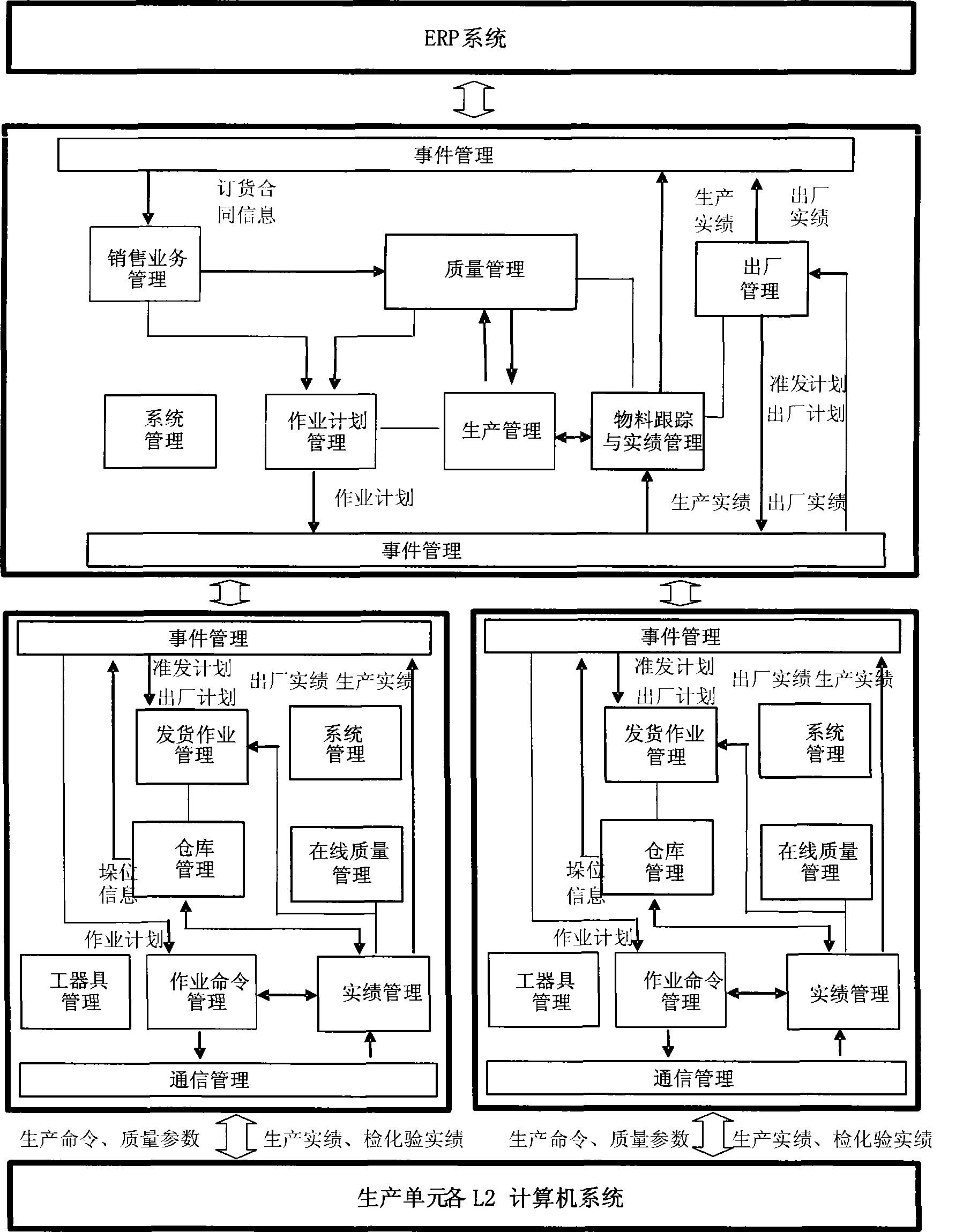

[0044] Such as figure 2 As shown, the layered MES software system architecture includes an upper-level manufacturing management system and a lower-level production execution system. The manufacturing management system is connected with the upstream EPR system, and the production execution system is connected with the downstream PCS process control system. The manufacturing management system and the Manufacturing Execution Systems are linked through the Efficient Event Handling Pattern.

[0045] The manufacturing management system mainly includes sales business management module, quality management module, production management module, operation plan management module, system management module, material tracking and performance management module and delivery management module; production execution system includes performance management module, delivery operation management module module, warehouse management module, job order management module, online quality management module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com