Pipe joint

A pipe joint and pipe body technology, which is applied in the direction of connection, rod connection, and connecting components, etc., can solve the problems of easy accumulation of dirt, falling off, and poor appearance of the pipe body connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Hereinafter, the present invention will be described with reference to the illustrated embodiments.

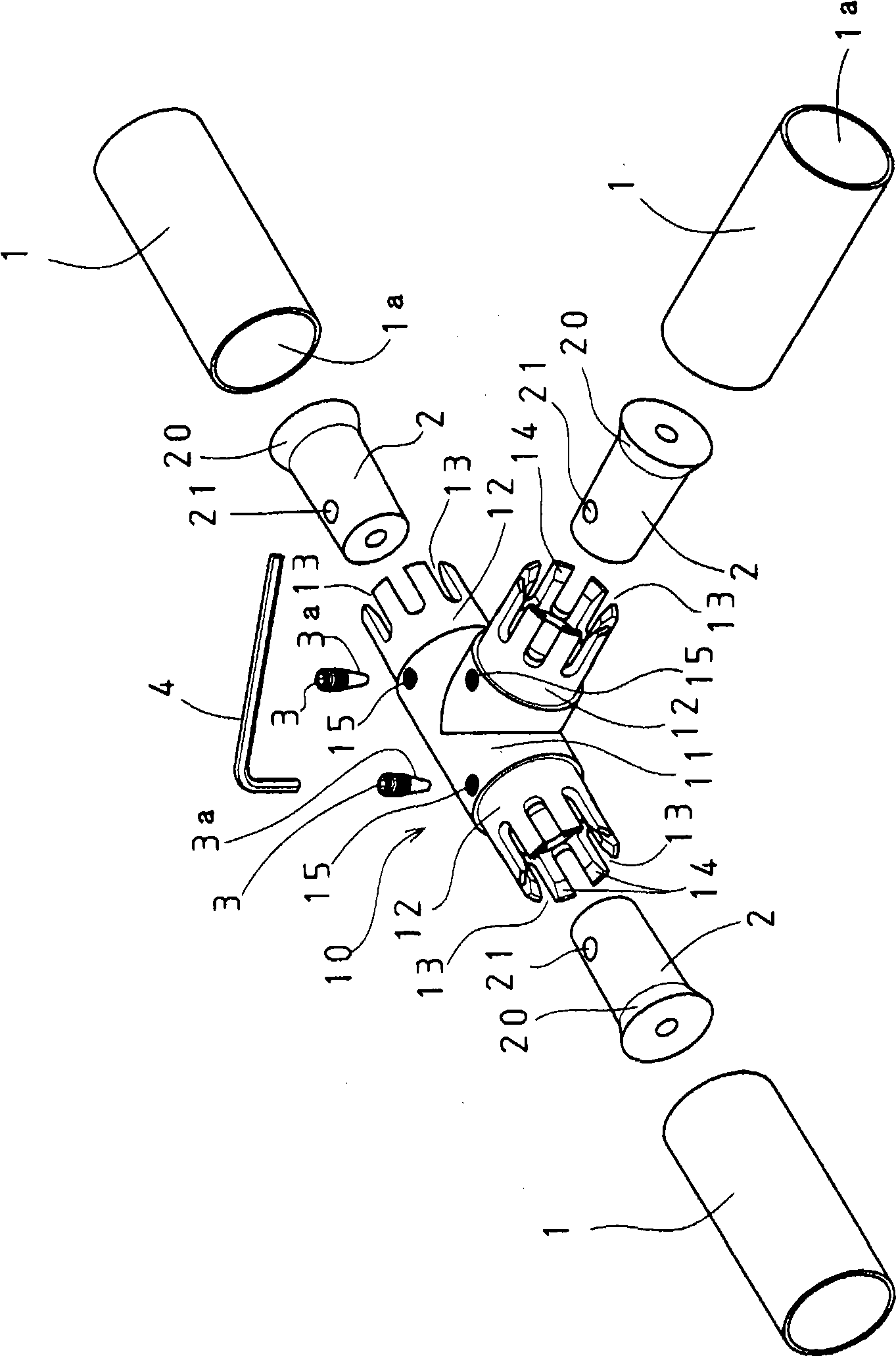

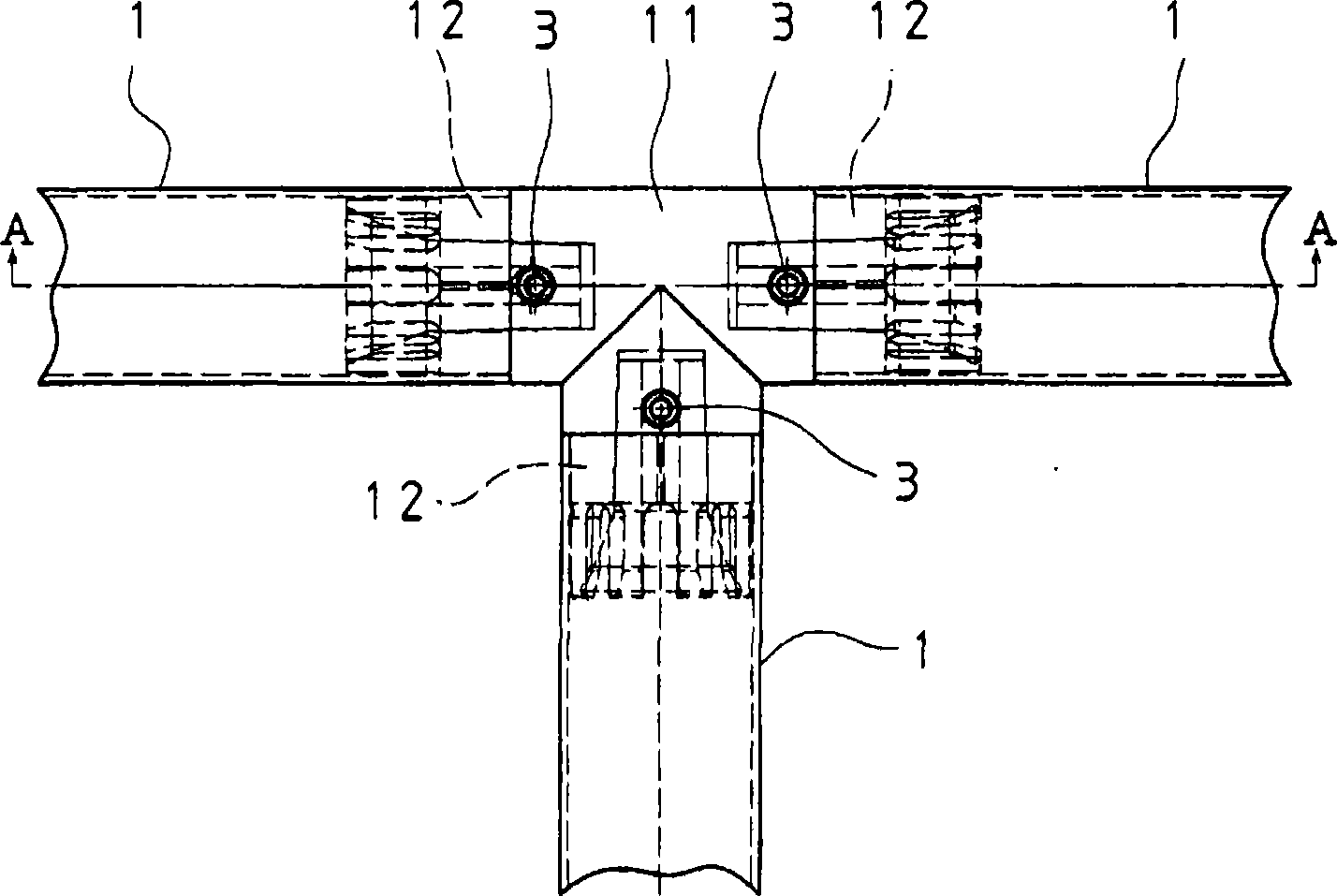

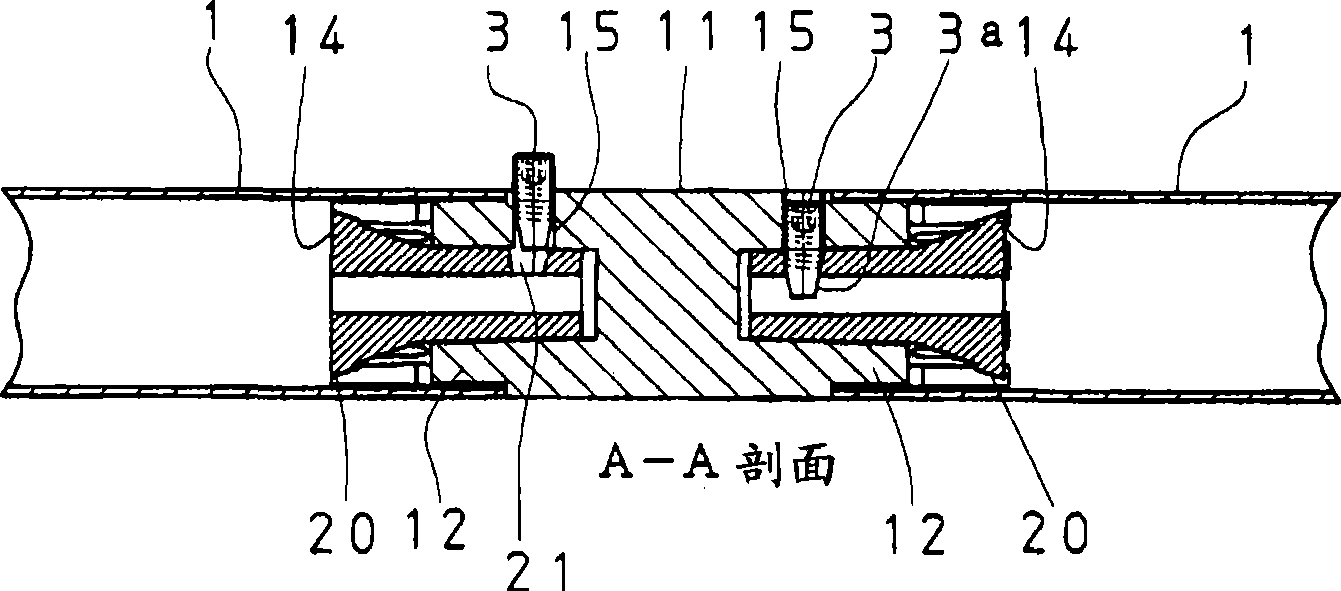

[0107] At first, Fig. 1-Fig. 3 are the embodiments of item 1 and item 2 in the present invention. In the case of the pipe body joint 10 of this embodiment, it protrudes from the joint body 11 and is inserted into the inner diameter portion 1a of the pipe body 1 that must be connected. In the embodiment of FIG. 1 , the three connection insertion parts 12 are hollow. structure. At the aforementioned insertion portion 12, the slit-shaped notches 13 that are nearly the entire length of the insertion portion 12 from its tip to the axial direction are formed in a plurality of substantially equal pitches in the circumferential direction, and the aforementioned insertion portion 12 is formed at Flexibility is given in the radial direction. The flexibility of the insertion portion 12 is to facilitate the insertion into the inner diameter portion 1a of the tubular body 1, and i...

Embodiment 2

[0126] Next, Fig. 7 shows an embodiment of the present invention described in item 3 and item 4 of the present invention.

[0127] The basic structure of the joint of the present embodiment 2 (Fig. 7) has a lot in common with the above-mentioned embodiment 1. That is, the connection insertion portion 12 protruding from the joint main body 11 and inserted into the inner diameter portion of the tubular body 1 to be connected has a hollow structure. At the aforementioned insertion portion 12, a plurality of slit-like notches with roughly equal pitches are formed in the circumferential direction from its tip to the axial direction, and at the hollow portion of the aforementioned insertion portion 12, an inner diameter is formed from the tip end thereof. The tapered portion 14 narrows toward the joint body 11. The joint is composed of a tapered sleeve 2 inserted into the hollow of the connection insertion portion 12 of the joint body 11, and a fixing bolt 3 having a tapered tapered ...

Embodiment 3

[0137] Next, Fig. 8 shows an embodiment of the present invention described in item 5 and item 6 of the present invention.

[0138] The joint of this embodiment 3 is also common to the above-mentioned embodiments 1 and 2 in many basic configurations. That is, the connection insertion portion 12 that protrudes from the joint body 11 and is inserted into the inner diameter portion of the pipe body 1 that must be connected has a hollow structure. At the aforementioned insertion portion 12, a plurality of slit-like notches with roughly equal pitches are formed in the circumferential direction from its tip to the axial direction, and, at the hollow portion of the aforementioned insertion portion 12, an inner diameter is formed from the tip end thereof. The tapered portion 14 narrows toward the joint body 11. The joint is composed of a tapered sleeve 2 inserted into the hollow of the connection insertion portion 12 of the joint body 11, and a fixing bolt 3 having a tapered tapered p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com