Thin film evaporator with film-climbing, film-falling and separating functions

An evaporator and thin-film technology, which is applied in the field of thin-film evaporators, can solve the problems of difficult cleaning of the deflector, damage to the stability of the evaporation system, and controllability of the easy-to-break liquid medicine, so as to reduce cross-contamination and facilitate automatic Control operation and make full use of thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

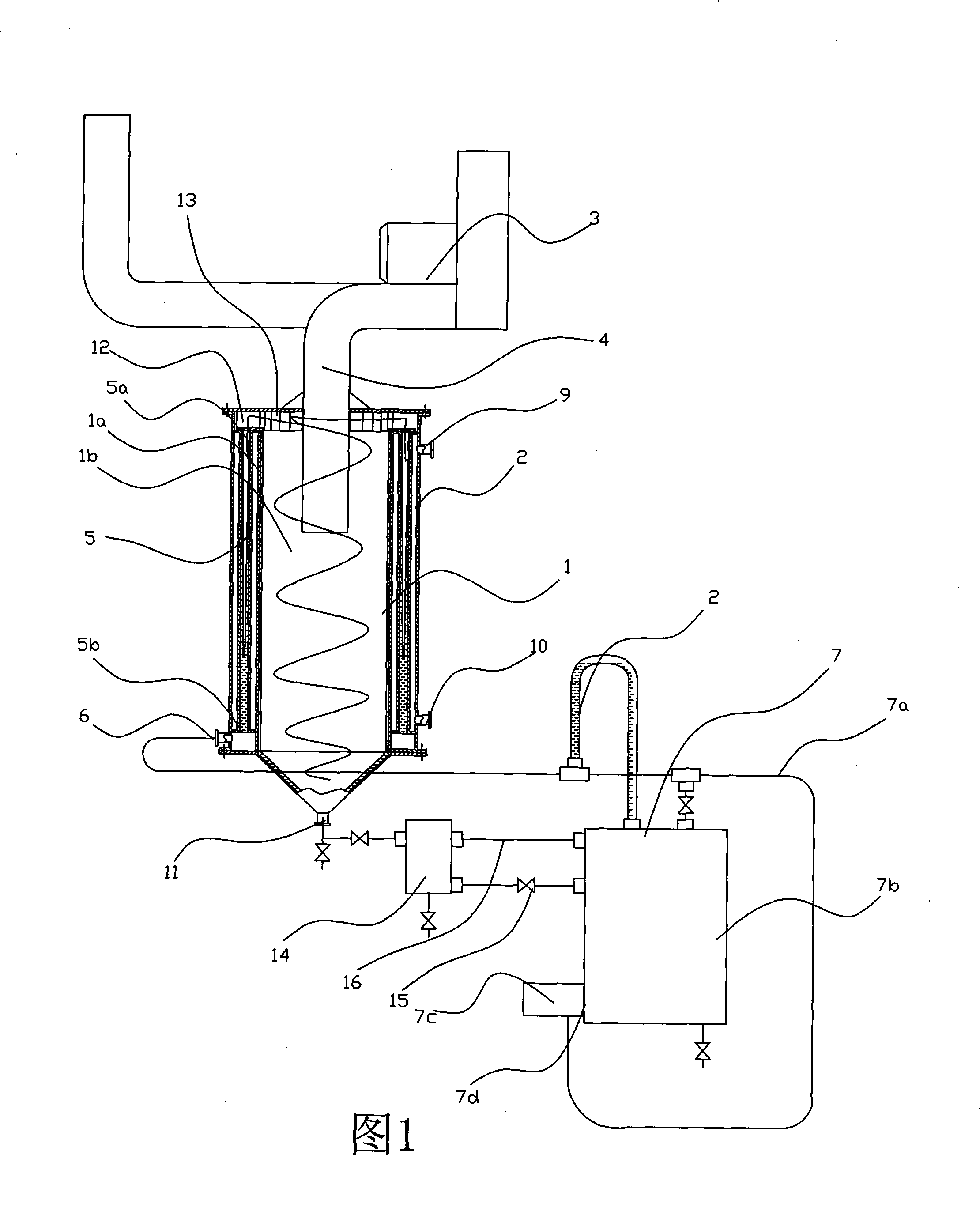

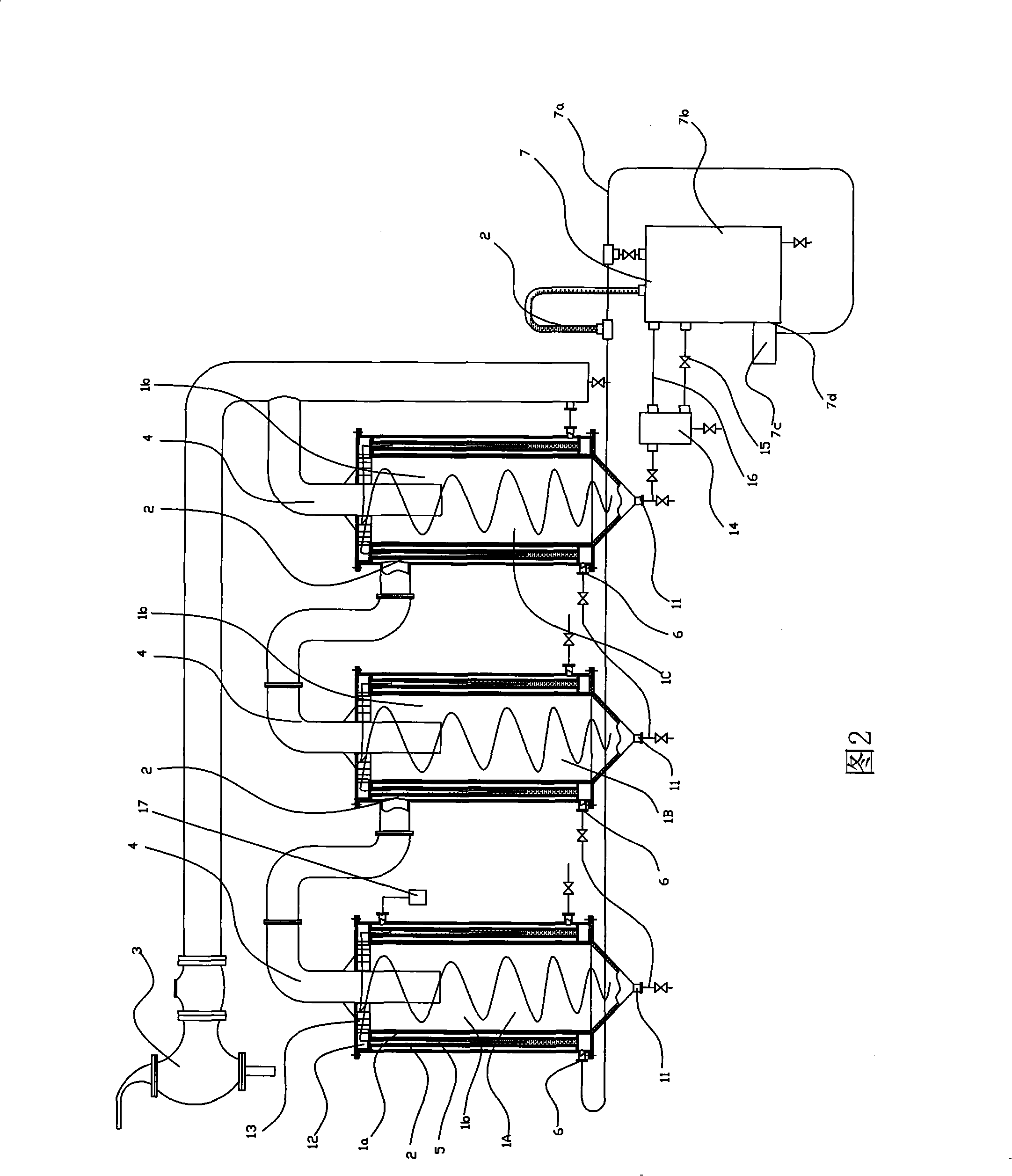

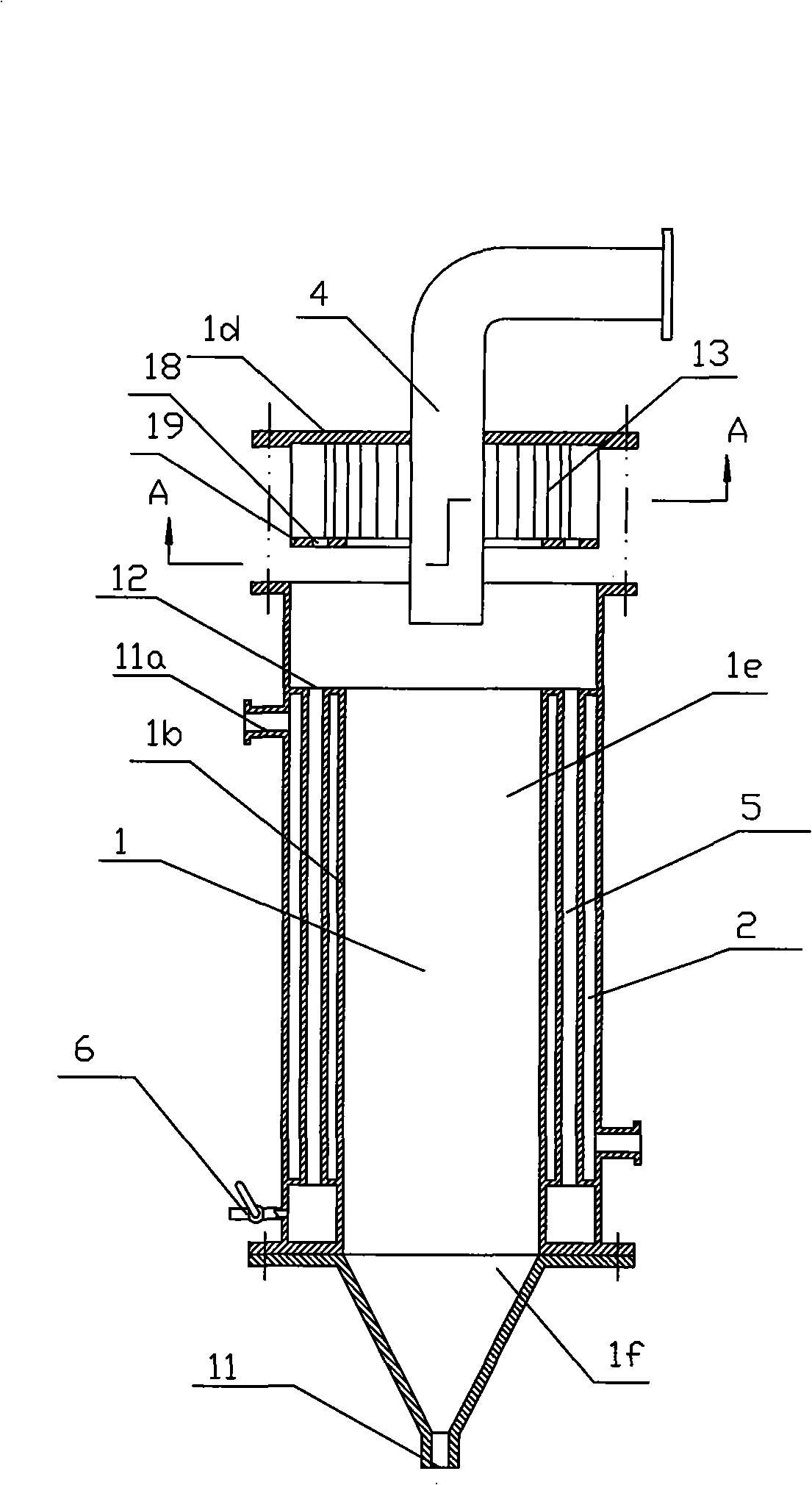

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0014] As shown in the figure, the present invention includes a cylindrical evaporator main body 2 with an interlayer 2 on the side wall 1a, a steam suction pipe 4 connected to a vacuum suction device 3 that goes deep into the inner cavity 1b of the cylindrical evaporator main body 1, and a vapor suction pipe 4 located in the interlayer 2. The inner upper port 5a communicates with the inner cavity 1b of the cylindrical evaporator main body 1, the lower port 5b communicates with the heating tube 5 connected with the liquid medicine inlet 6, the medicine liquid delivery device 7 communicated with the medicine liquid inlet 6, and the medicine liquid delivery device 7 located in the medicine liquid The liquid level control device 8 on the delivery pipe 7a of the liquid delivery device 7, the interlayer 2 communicates with the high-temperature steam delivery por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com