Method for realizing multi-color-class positioning cold wave transfer printing

A technology of transfer printing and cold stamping, which is applied to rotary printing machines, general parts of printing machinery, printing, etc., and can solve problems such as difficult on-line hot stamping, inability to transfer halftone layers, and high product consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

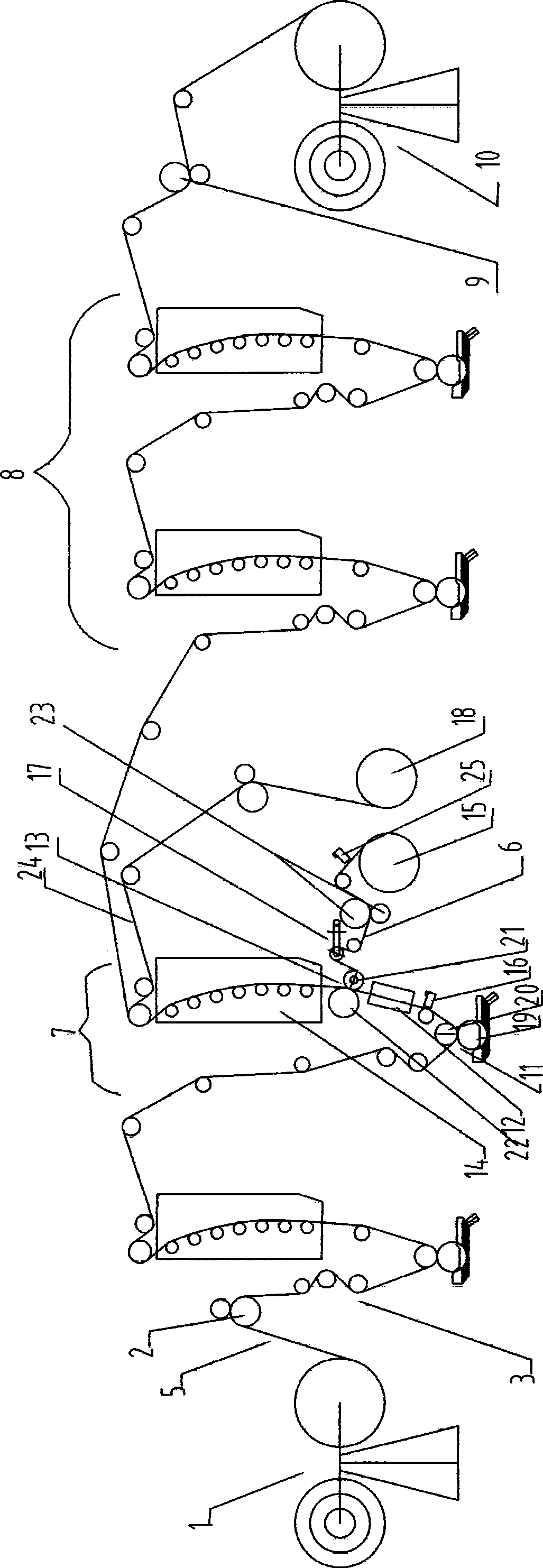

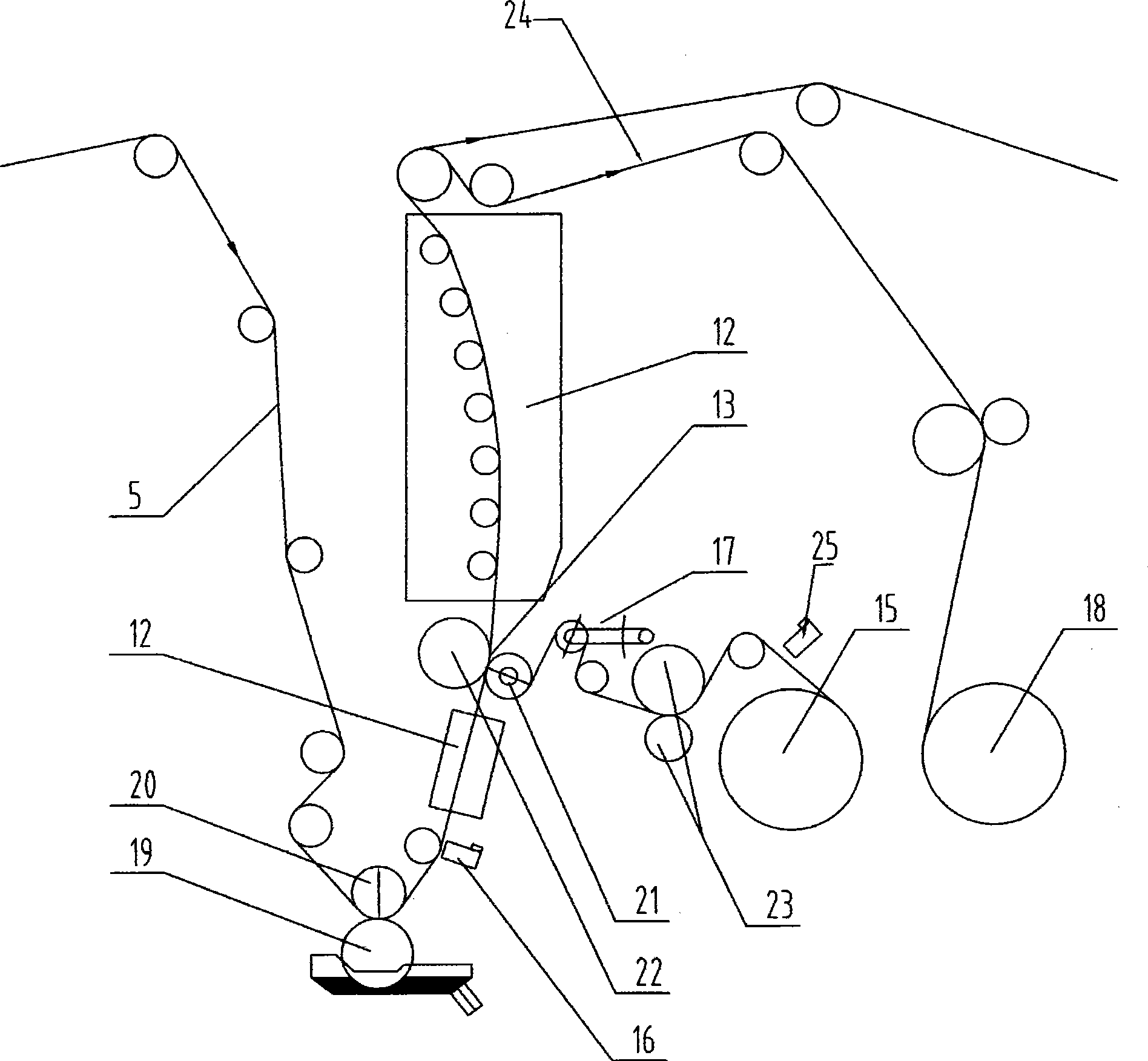

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The method for realizing multi-color group positioning cold ironing transfer film is applicable to gravure printing, flexographic printing and offset printing, and can be realized by the following steps:

[0018] a. First put the roll paper into the unwinding device 1 of the printing press; b. Pull out the roll paper and pull it to the feeding traction roller 2; c. The paper 5 coming out of the feeding traction roller 2 enters the The first printing color group 3 is used to print patterns; d, after the first printing color group 3 is printed, the paper 5 enters the cold ironing transfer unit 7, and the transfer film 6 placed in the cold ironing transfer unit 7 is overprinted and transferred on the paper 5 ; e, after overprinting by the cold stamping transfer unit 7, and then printing through multiple sets of printing color groups 8; f, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com