Method of operating a spinning station of a semiautomatic open end spinning frame and spinning station to implement the method

A technology of workstations and free ends, applied in the field of workstations, can solve the problem of no movable service components, etc., and achieve the effect of reducing yarn waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

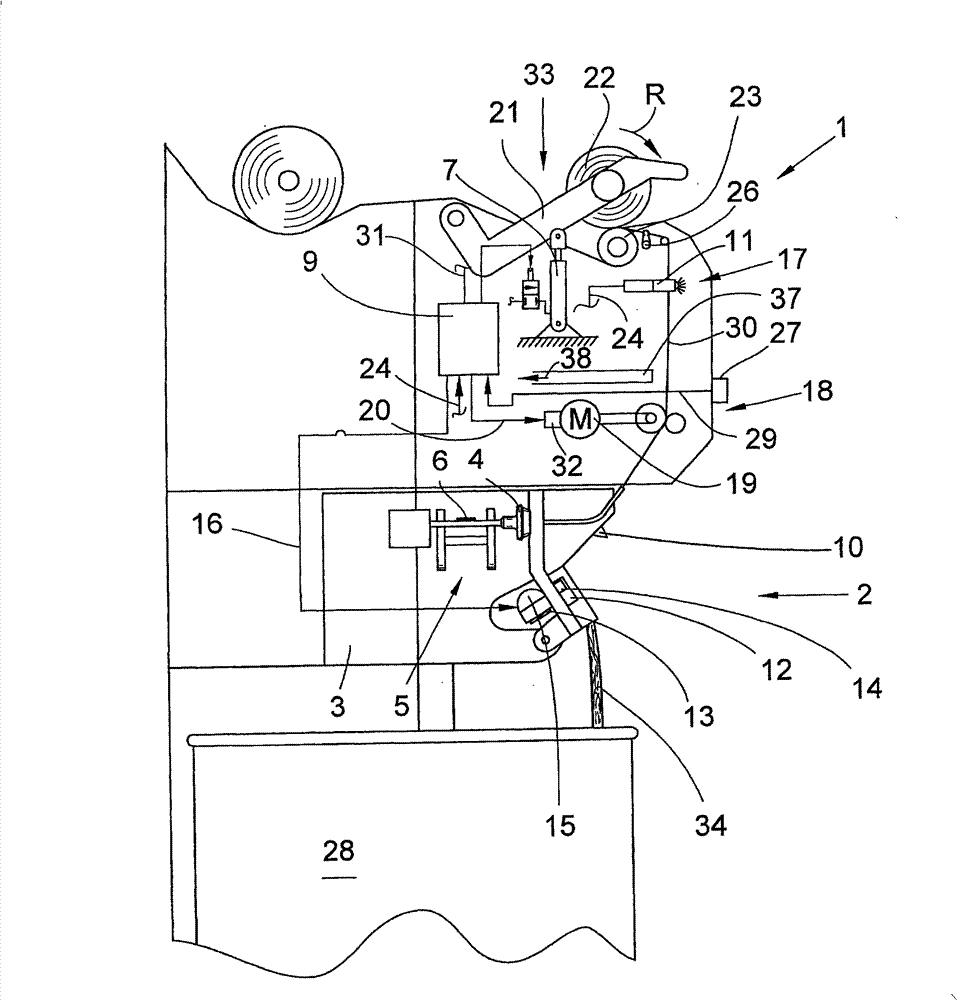

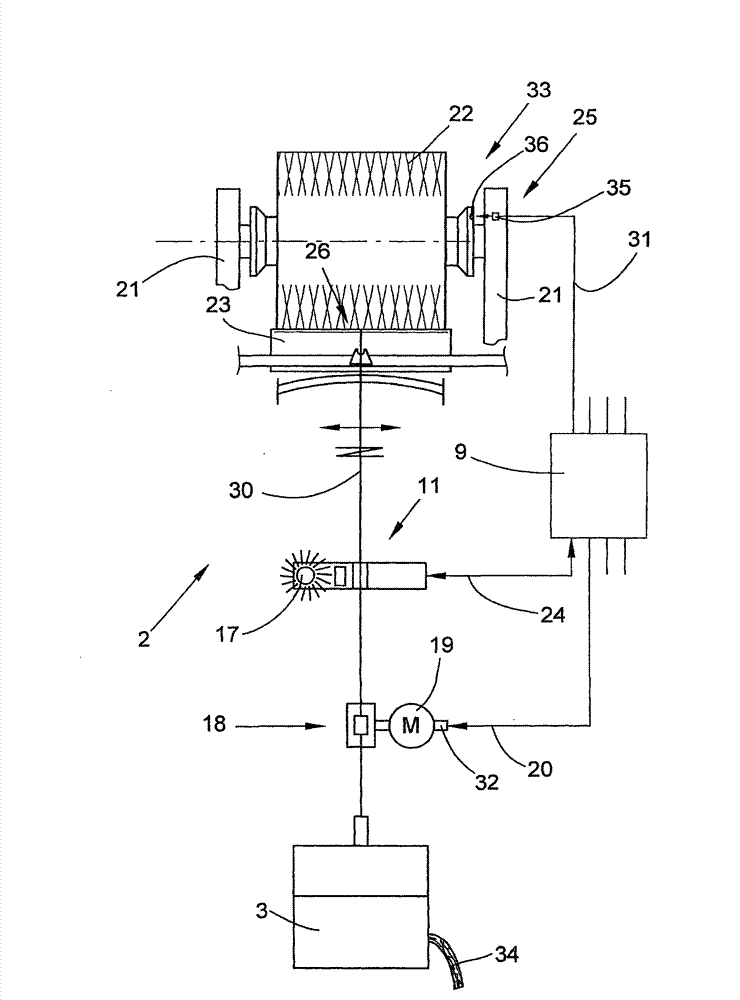

[0019] figure 1 and figure 2 Respectively shown are a side view and a front view of the workstation 2 of the semi-automatic open-end spinning machine 1 . Spinning machines of this type are known to have a plurality of workstations 2 of the same type arranged one after the other in a row, each having a spinning device 3 and a winding mechanism 33 as important functional elements.

[0020] In the spinning device 3 , the fiber sliver 34 fed into the spinning can 28 is spun into a yarn 30 , which is then wound into a cross-wound package 22 on a winding device 33 . As known per se, the winding mechanism 33 has for this purpose respectively: the creel 21 for rotatably holding the bobbin of the cross-wound bobbin 22, the bobbin drive roller 23, the yarn traversing mechanism 26, and the The mechanism 7 for cross-winding the bobbin 22 is lifted from the bobbin drive roller 23 . The mechanism 7 is configured, for example, as a thrust piston drive, which is connected via a pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com