Hydraulic gravity force type vertical ship lift

A vertical ship lift and gravity-type technology, applied in the field of ship lifts, can solve the problems of large mechanical equipment and difficult manufacturing, and achieve the effect of direct driving mechanism, easy manufacturing and simple driving mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

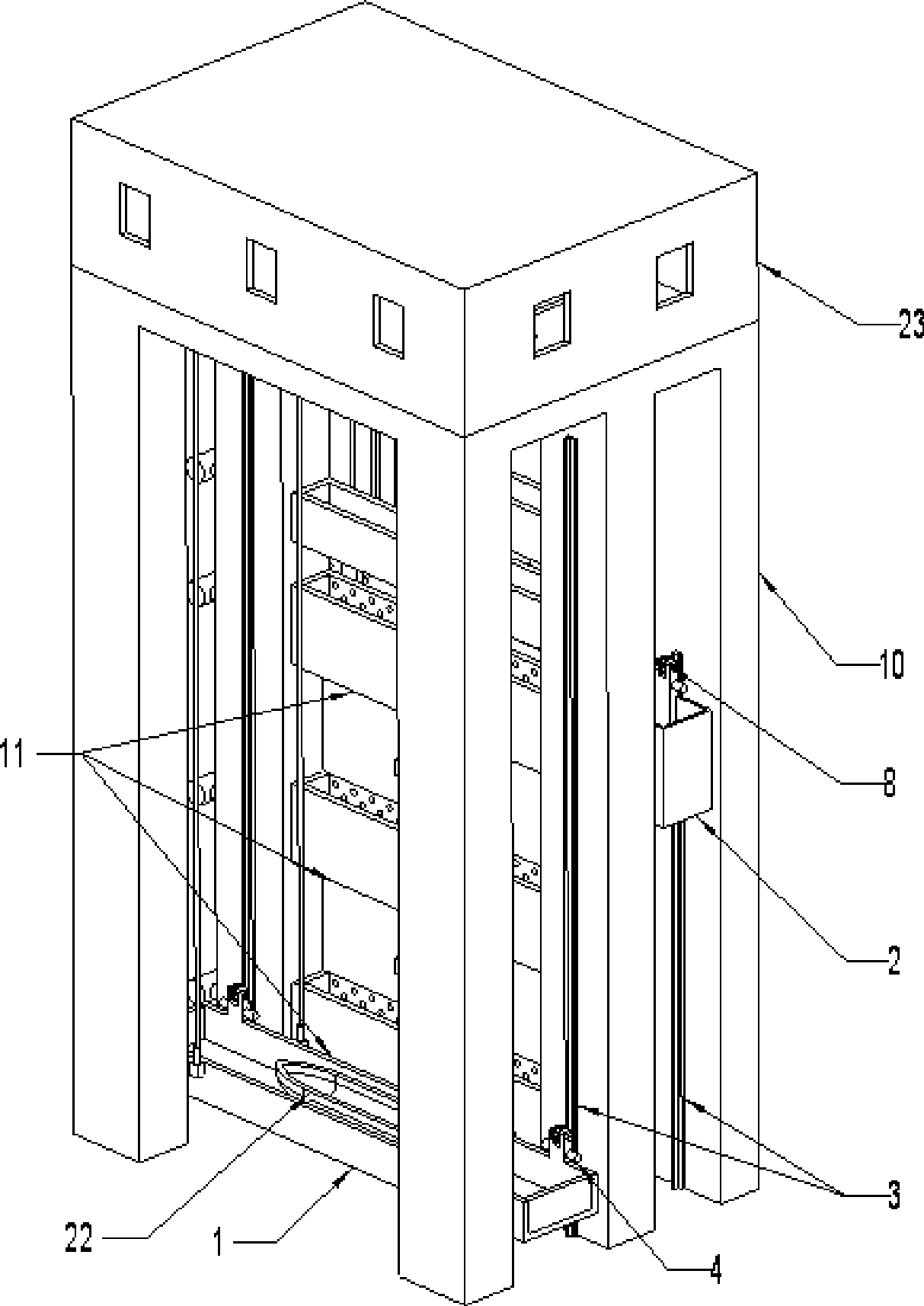

[0019] figure 1 It is the overall schematic diagram of the hydraulic gravity type vertical ship lift proposed by the embodiment of the present invention. In the figure, the dam-crossing ship (22) is in the ship compartment (1), and the ship compartment (1) and the gravity water compartment (2) form a balanced counterweight, and the guide rail (3) and the guide rail wheel (8) play a stable role when running. The building support (10) is a reinforced concrete structure, the water storage box (11) can be made of composite boards or concrete, and the top floor machine room (23) is a concrete structure.

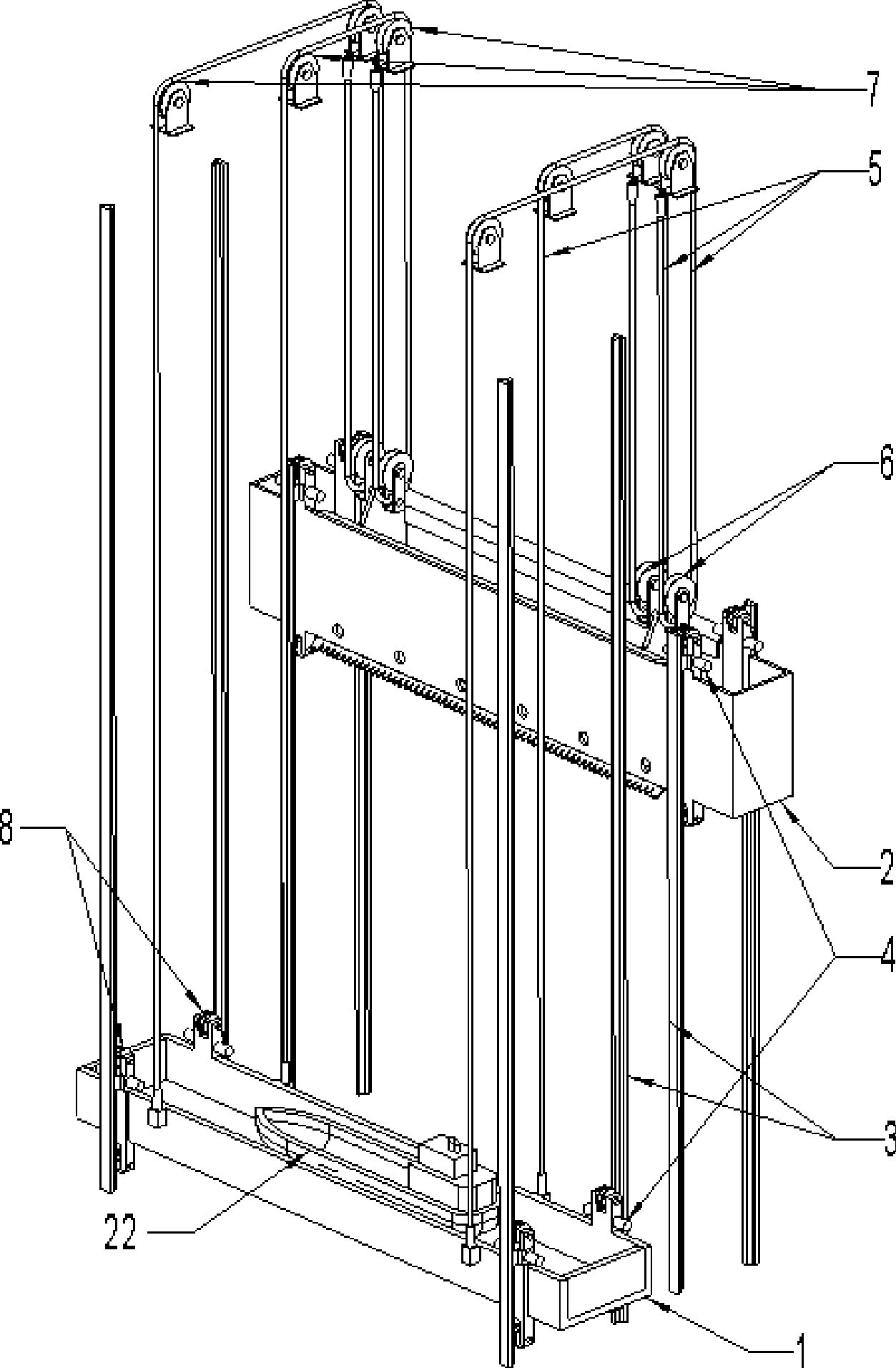

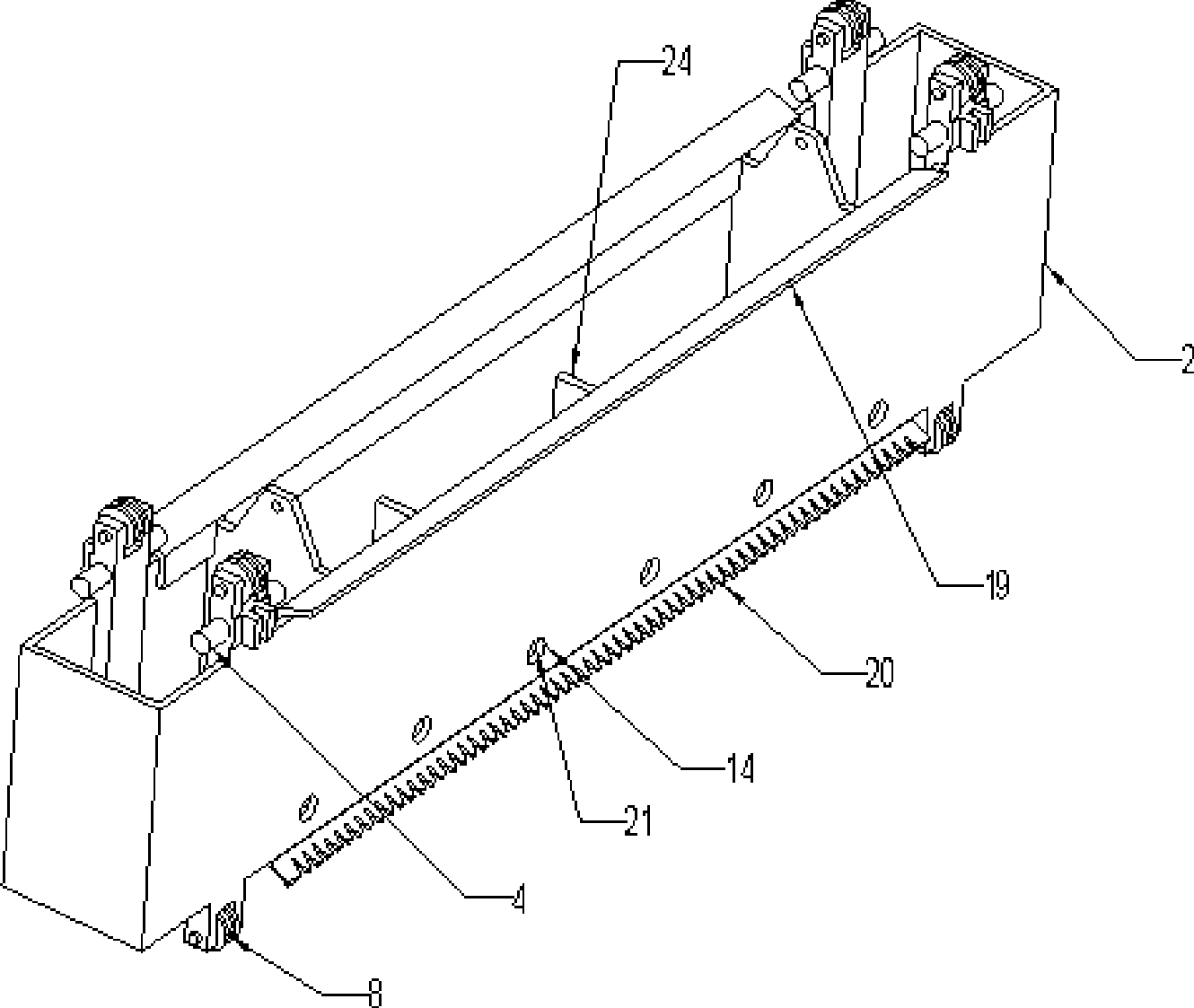

[0020] see figure 2, through the pulley block and the wire rope winding system (5) of the reel, the ship compartment (1) and the gravity water compartment (2) are connected in a balanced manner on both sides, and the gravity water compartment (2) balances the ship compartment (1) Due to the counterweight, this structure makes the lifting points of the ship box (1) and the gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com