A kind of preparation method of preparing 3-methylthiopropanol from 3-methylthiopropionaldehyde

A technology of methylthiopropanol and methylthiopropionaldehyde, which is applied in the preparation of sulfides and organic chemistry, can solve the problems of reducing the reduction activity of sodium borohydride or lithium aluminum hydride, and achieve high yield, cost reduction, Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method provided by the present invention directly prepares 3-methylthiopropanol from 3-methylthiopropanal (MMP) by using a reducing agent and 3-methylthiopropanol, and the preparation method is straightforward and easy to realize industrialized quantities Produce. 3-Methylthiopropanol is a weaker acid than methanol, therefore, the reducing agent is stable in 3-Methylthiopropanol for several hours. In order to avoid thermal decomposition reaction of 3-methylthiopropanal (MMP) due to runaway heat release, special attention should be paid to the addition of reducing agent and temperature control.

[0030] In a preferred embodiment, the specific steps of the preparation method provided by the present invention are as follows: Add the reducing agent to 3-methylthiopropanol at a temperature of 0° C. to obtain a suspension. Slowly add 3-methylthiopropanal (MMP) dropwise to the obtained suspension while controlling the temperature below 20° C. to avoid side rea...

Embodiment 1

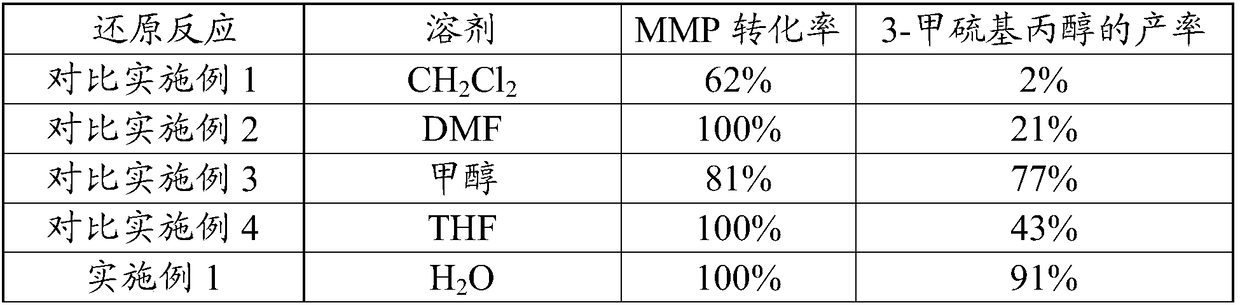

[0032] Table 1 is the influence of different solvents on the preparation of 3-methylthiopropanol from 3-methylthiopropanal (MMP). At a temperature of 0°C, an excess of 10% of the reducing agent sodium borohydride (NaBH 4 ) was added into 30mL solvent to obtain a suspension. Then, 10 g of 3-methylthiopropanal (MMP) was slowly added dropwise to the resulting suspension while controlling the temperature below 20°C. After the dropwise addition is completed, stir at room temperature, and after 3-12 hours, add HCl solution to the reaction solution for hydrolysis. After hydrolysis, the resulting reaction solution was evaporated under reduced pressure to remove water in the reaction solution. Filter to remove the sodium chloride generated by hydrolysis in the reaction solution, and use 10 mL of cold methanol solution to wash the filter residue, and further extract the product 3-methylthiopropanol in the filter residue. Finally, the mixed solution obtained after washing and the filt...

Embodiment 2

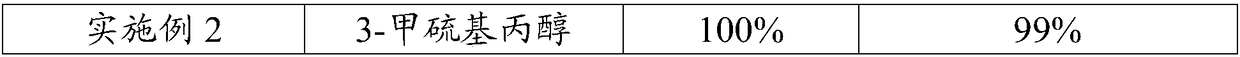

[0038] Table 2 is the influence of different amounts of reducing agent on the preparation of 3-methylthiopropanol from 3-methylthiopropanal (MMP). Add sodium borohydride (NaBH 4 ) into 30 mL of 3-methylthiopropanol solvent to obtain a suspension. Then, 10 g of 3-methylthiopropanal (MMP) was slowly added dropwise to the resulting suspension while controlling the temperature below 20°C. After the dropwise addition is completed, stir at room temperature, and after 3-12 hours, add hydrochloric acid (HCl) solution to the reaction solution for hydrolysis. After hydrolysis, the resulting reaction solution was evaporated under reduced pressure to remove water in the reaction solution. Filter to remove the sodium chloride generated by hydrolysis in the reaction solution, and use 10 mL of cold methanol solution to wash the filter residue, and further extract the product 3-methylthiopropanol in the filter residue. Finally, the mixed solution obtained after washing and the filtrate wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com