Rubber plug system used for drilling liner cementing of horizontal well

A technology of rubber plug and tail pipe, which is applied in the field of rubber plug system to achieve the effect of improving reliability and cementing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment, further illustrate the present invention.

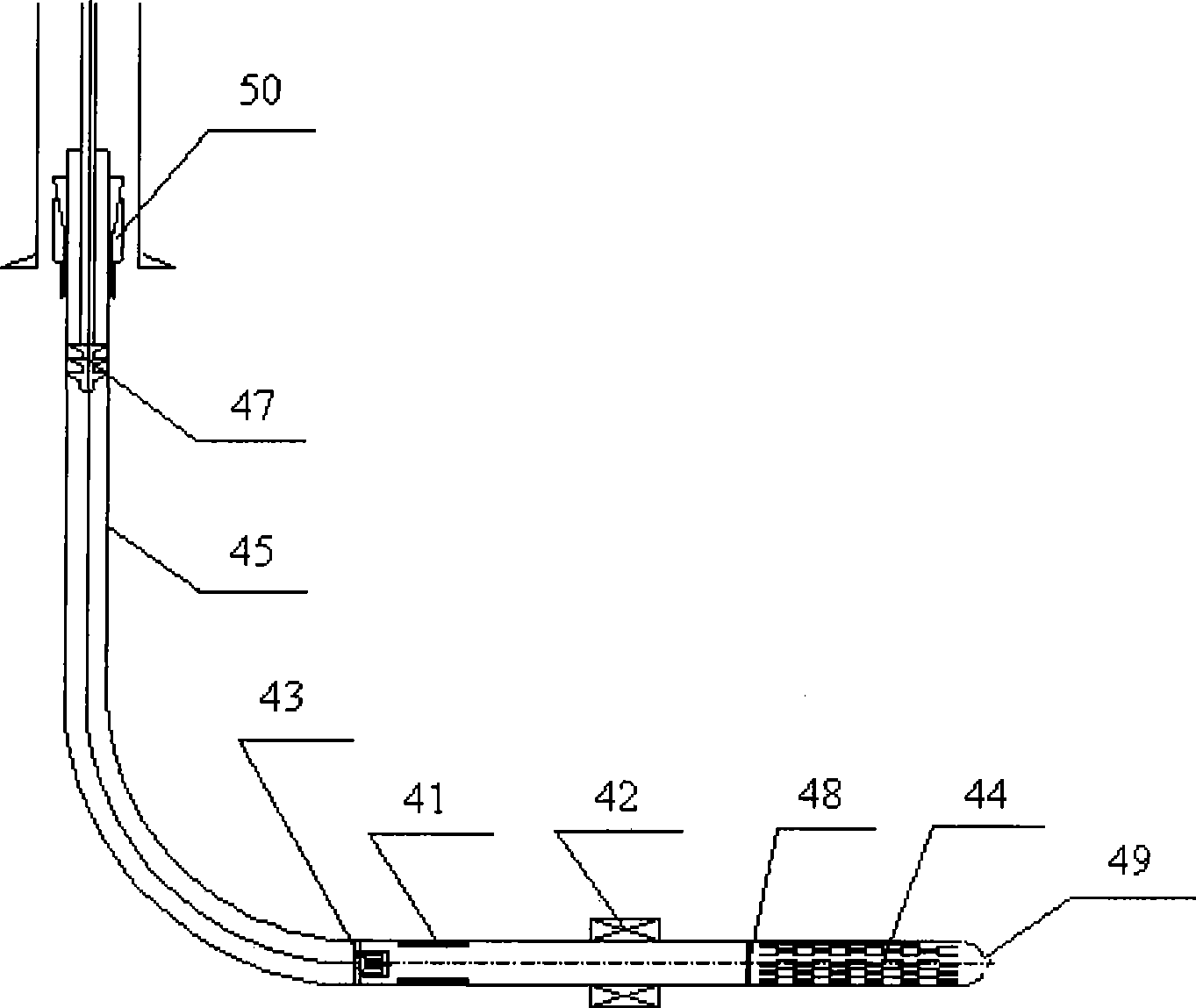

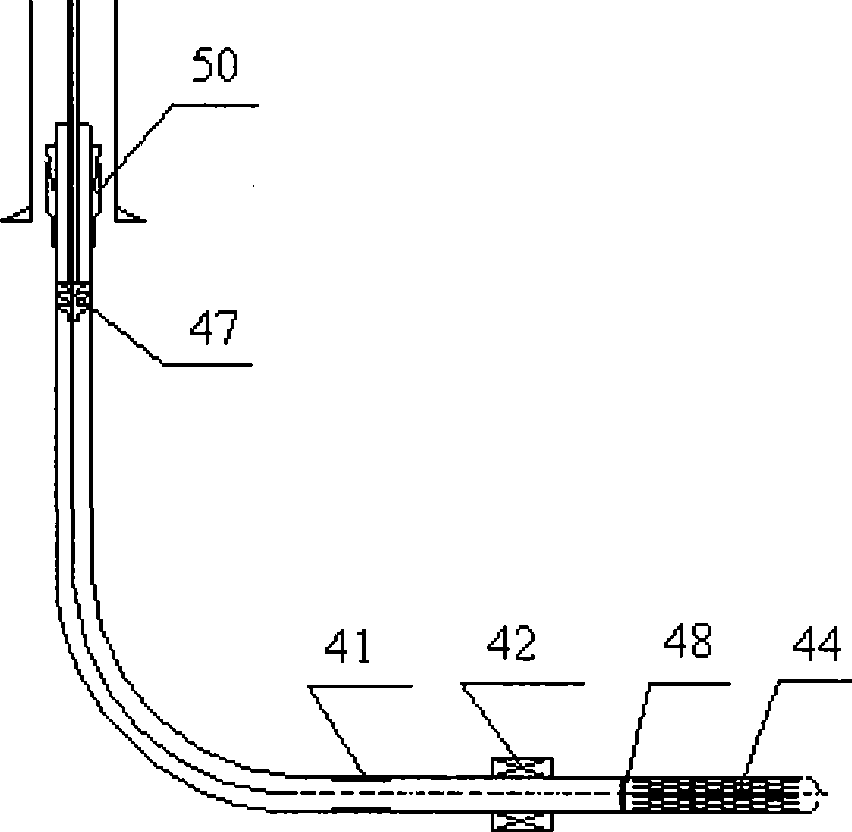

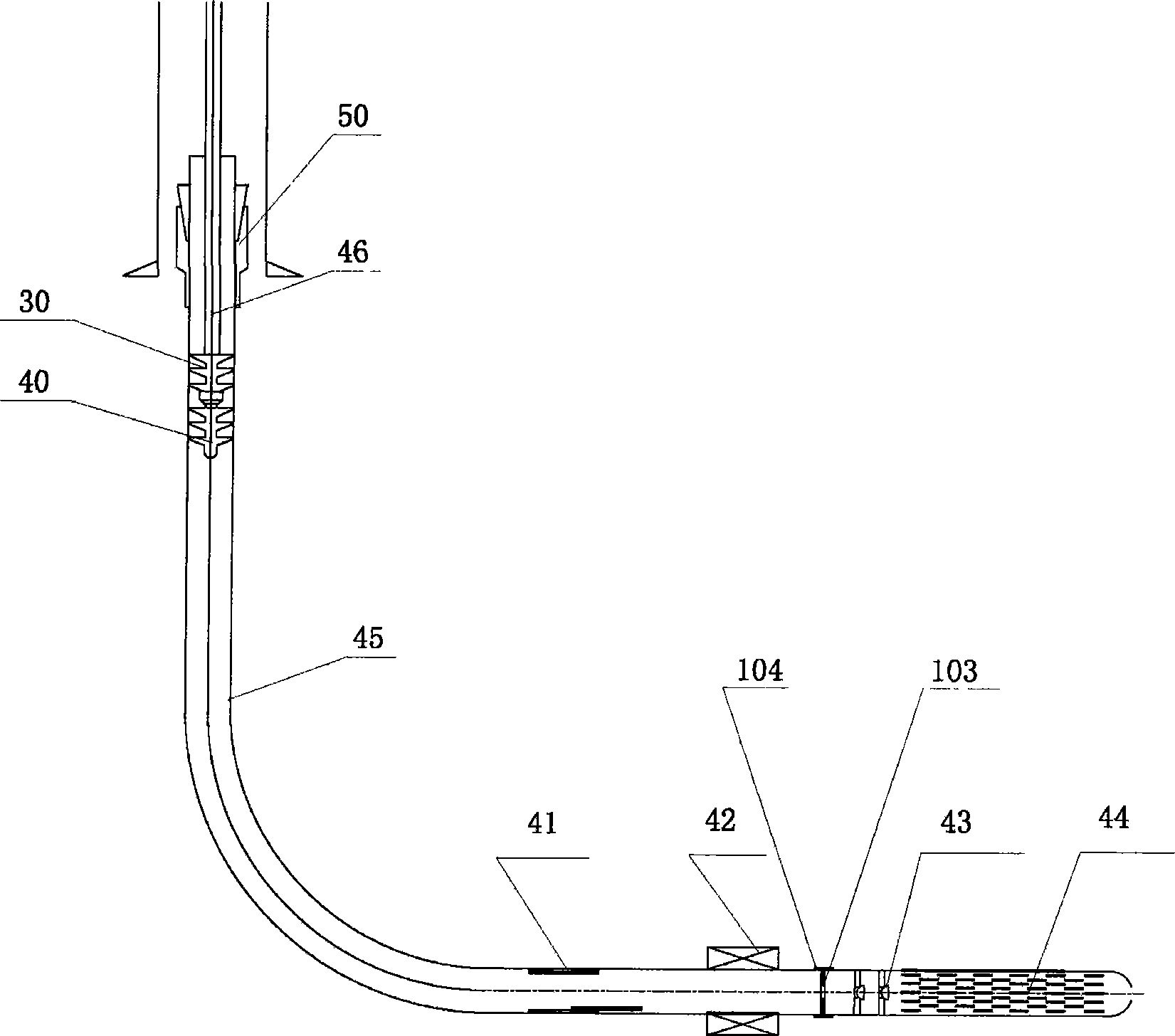

[0030] Figure 5 Shown is the joint 10 in the rubber plug system of the present invention, the connecting sleeve 20 and the connection structure of the tail pipe closing rubber plug 30 and the lower rubber plug 40 in the rubber plug assembly. Both the joint 10 and the connecting sleeve 20 are of cylindrical structure. The smallest diameters of the inner walls of the joint 10 and the connecting sleeve 20 are both greater than the diameter of the pitching ball 27 . There are threads on the outer walls of the upper and lower ends of the joint 10, and the upper end of the joint 10 is threaded with the lower end of the central pipe of the tailpipe feeding tool, and the lower end is threaded with the inner wall of the connecting sleeve 20. The lower end of the inner wall of the connection sleeve 20 is provided with an inclined surface shoulder 8 .

[0031] Such as Figure 5 The shown tail pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com