Method for reducing OPC model residual error

A residual error and model technology, applied in the field of reducing the residual error of the OPC model, can solve the problem of low precision of the OPC model, achieve the effect of improving the correction efficiency, reducing the residual error of the model, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

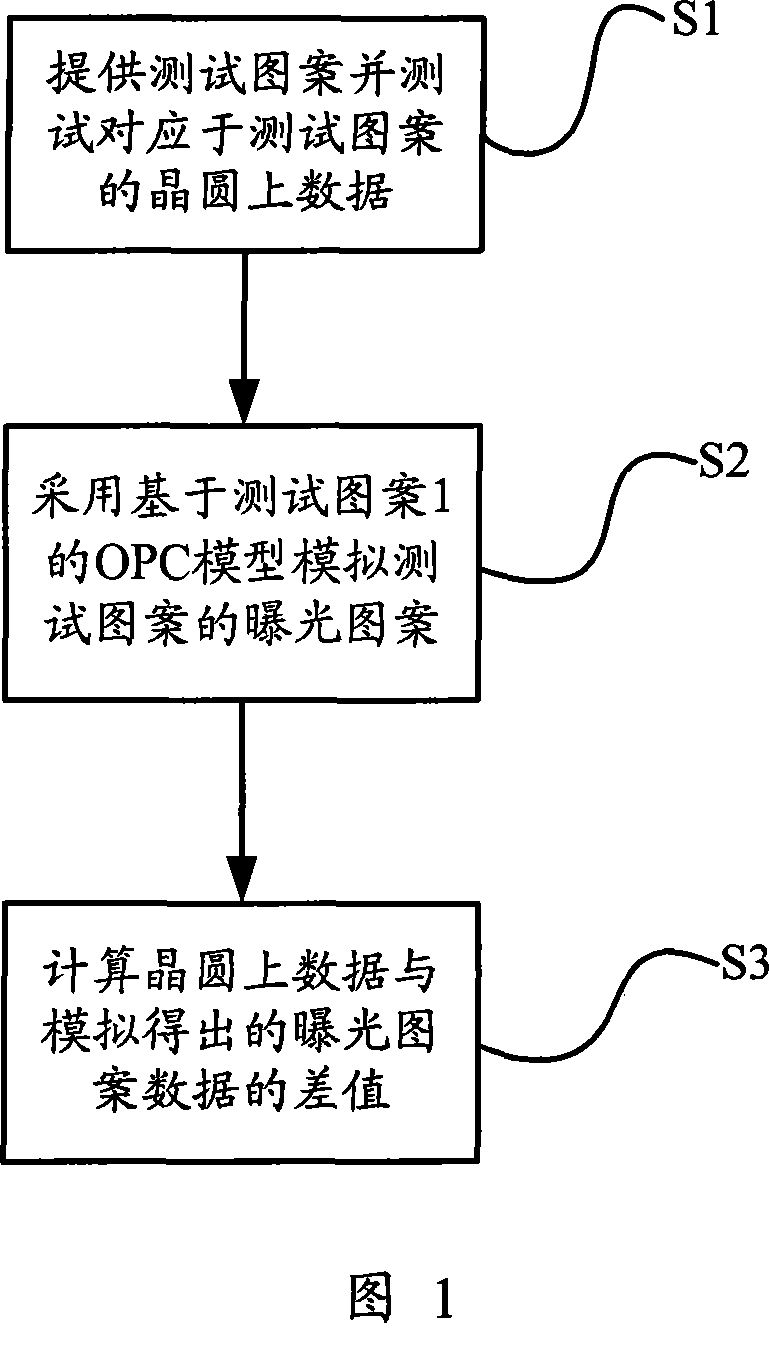

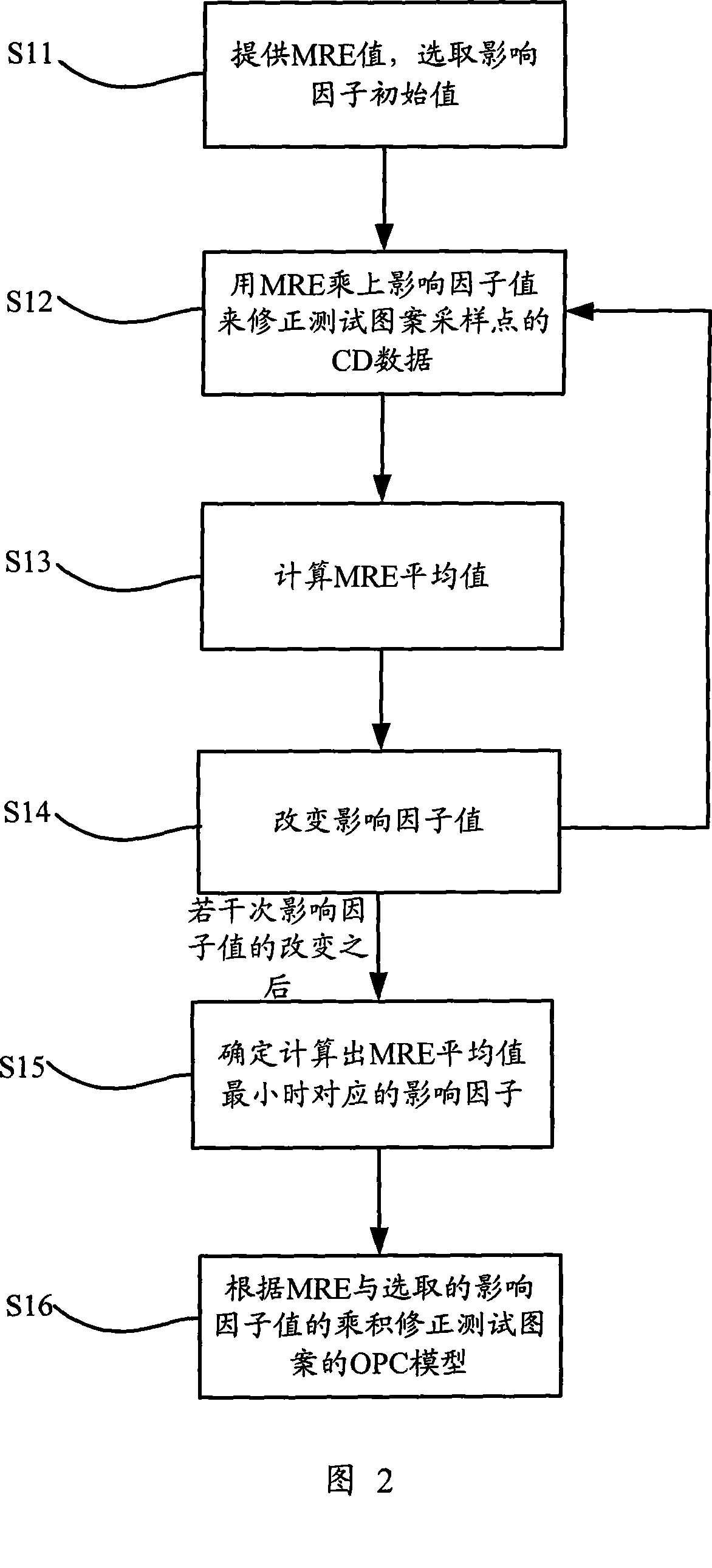

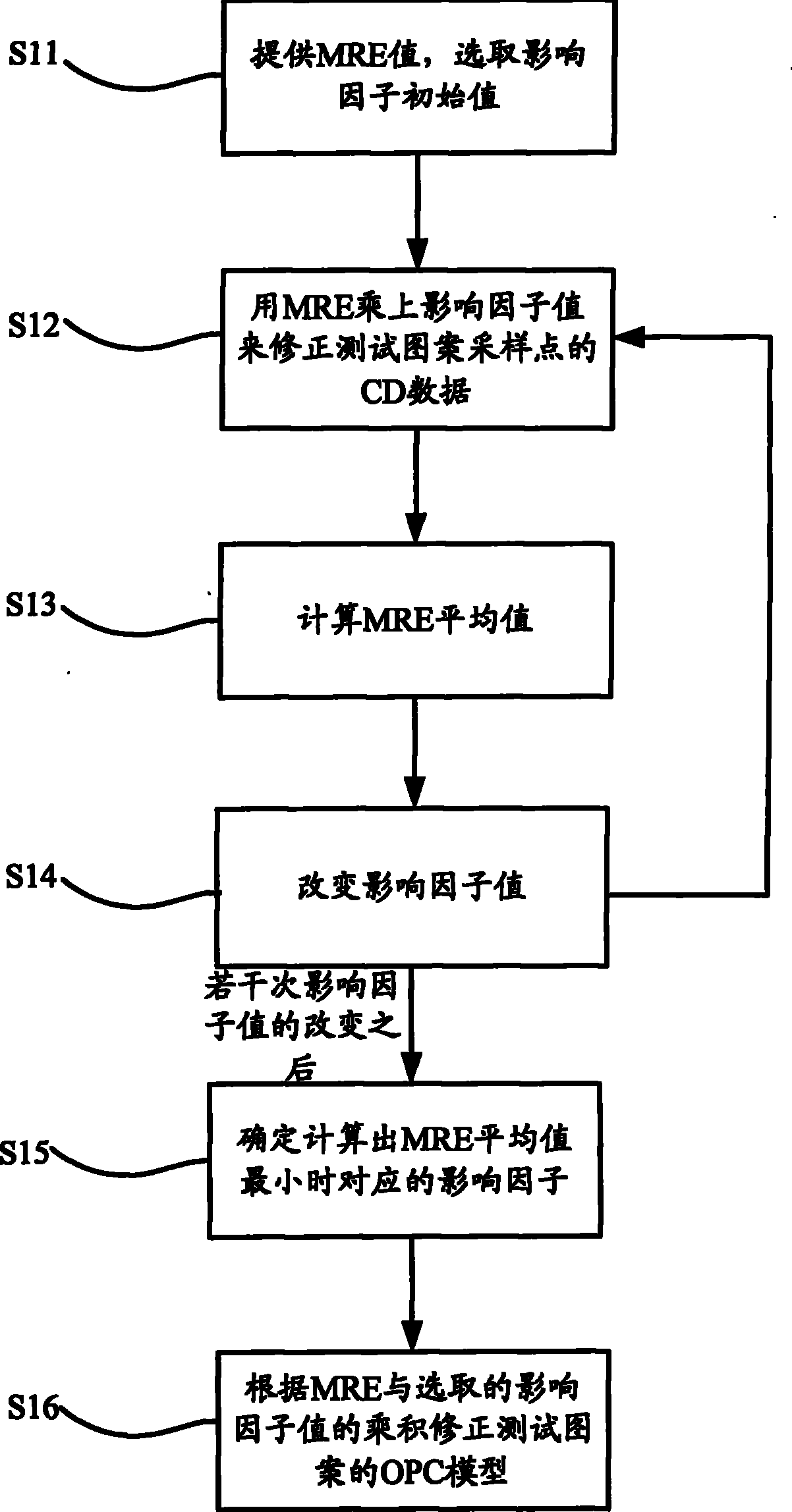

[0014] For the schematic diagram of the method of obtaining the residual error of the OPC model, please refer to figure 1 . It has been described in detail above, so it will not be repeated here. For the method of reducing the residual error of the OPC model of the present invention, please refer to figure 2 . It consists of six steps in total. Step S11 , providing model residual error values for a series of sampling points on the test pattern, and selecting an initial value of the influencing factor. The model residual error values for a series of sampling points on the test pattern can be obtained by figure 1 obtained by the method shown. In step S12, the CD data of the sampling points on the test pattern is corrected after multiplying the model residual error values of all the sampling points on the test pattern by the value of the impact factor. However, the value of the influence factor multiplied by the model residual error of all sampling points of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com