Power transmission control device, non-contact power transmission system, power transmitting device, electronic instrument, and waveform monitor circuit

A power transmission device and power transmission technology, applied in circuit devices, electromagnetic wave systems, battery circuit devices, etc., to achieve accurate initial fault detection, improve reliability, safety, and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0073] First, examples of preferable electronic equipment to which the present invention is applied and the principle of non-contact power transmission technology will be described.

[0074] (Examples of electronic devices and principles of contactless power transmission)

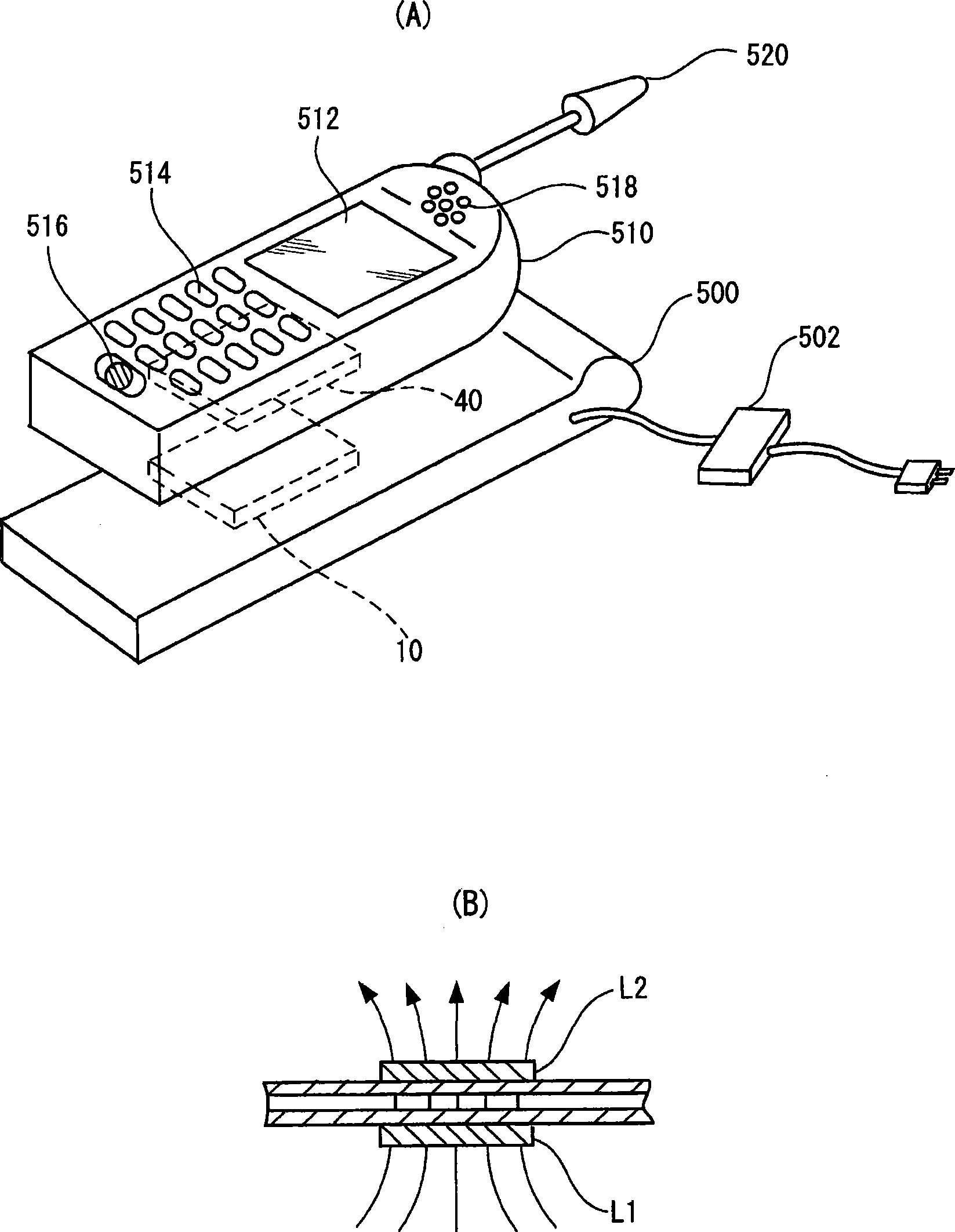

[0075] figure 1 (A) and figure 1 (B) is an explanatory diagram for explaining an example of an electronic device to which the non-contact power transmission method is applied and the principle of the non-contact power transmission using an induction transformer.

[0076] Such as figure 1 As shown in (A), a charger (cradle) 500 as a power transmission-side electronic device includes a power transmission device (such as a power transmission module including a power transmission-side control circuit (power transmission-side control IC)) 10 .

[0077] A mobile phone 510 as a device on the power receiving side has a power receiving device (a power receiving module including a power receiving side control c...

no. 2 approach

[0174] In this embodiment, an example of a specific circuit configuration of the power transmission unit will be described.

[0175] (Example of the specific internal circuit configuration of the power transmission control device and the power transmission unit)

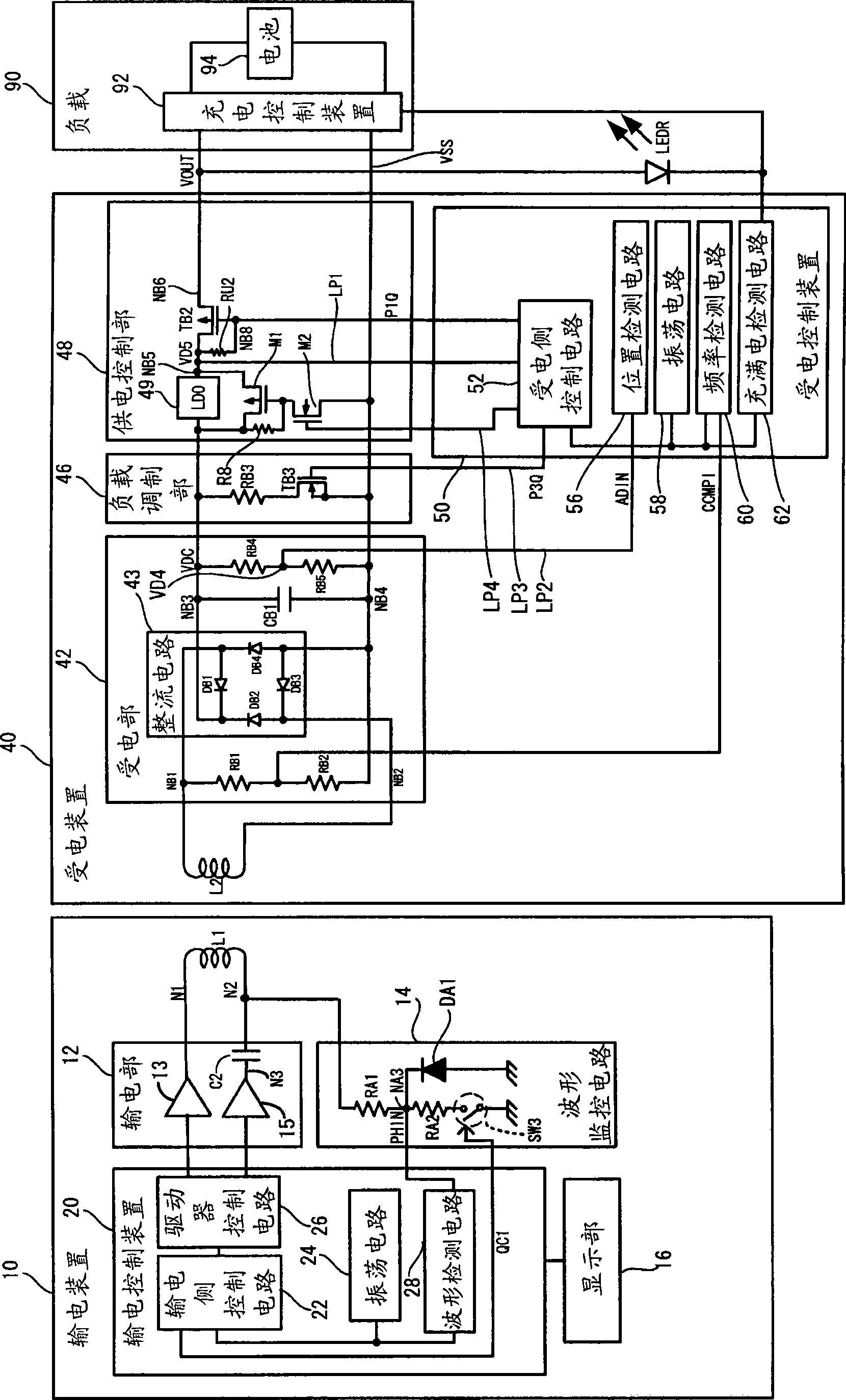

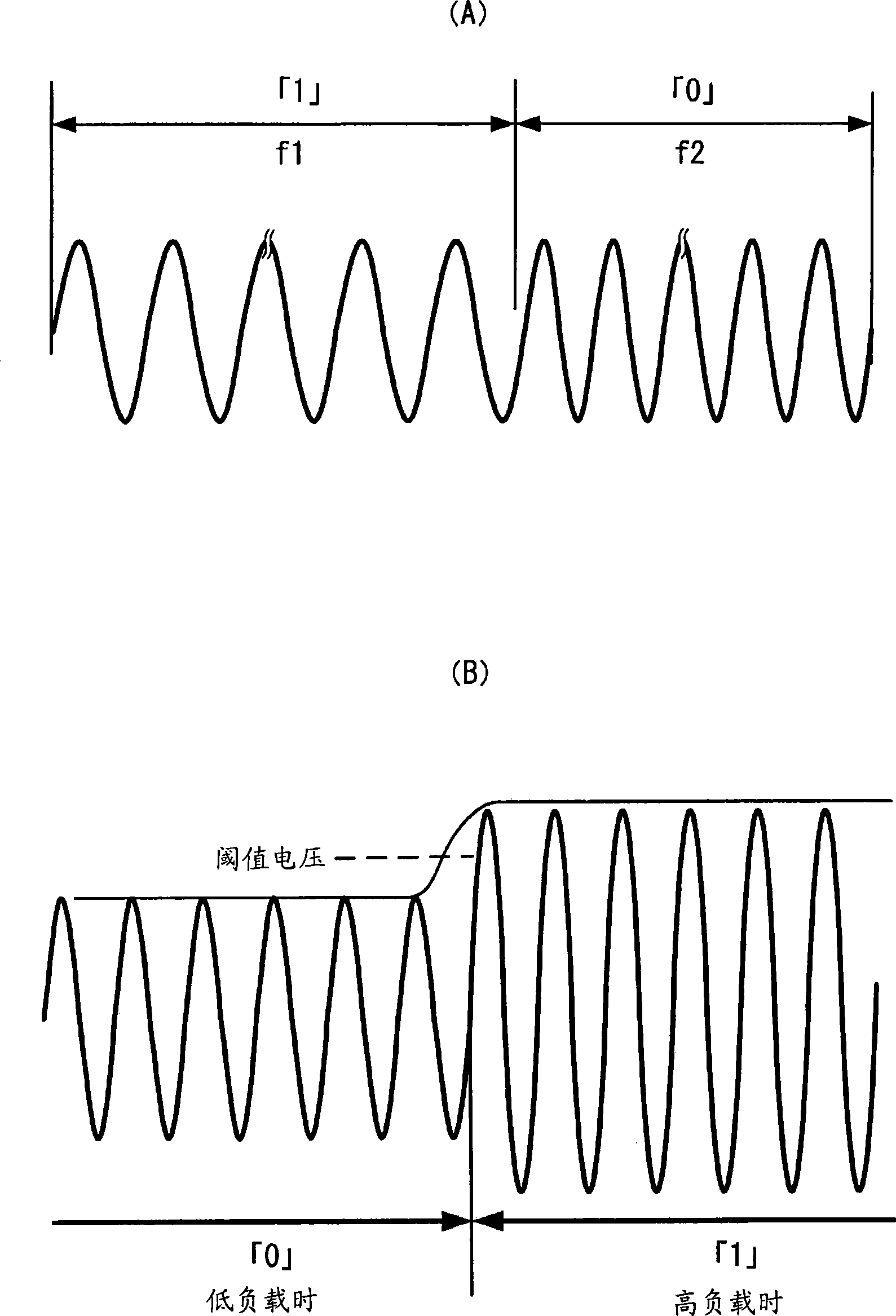

[0176] Figure 10 It is an example block diagram showing the specific internal circuit configuration of the power transmission control device and the power transmission unit. exist Figure 10 in, with figure 2 The same parts are marked with the same reference numerals. exist Figure 10 Among them, a switch SW3 is provided in the waveform monitoring circuit 14, and the switch SW3 is turned off when an initial failure is detected. and, in Figure 10 Among them, the switch SW3 provided in the waveform monitoring circuit 14 is composed of an NMOS transistor MSK. On / off of the NMOS transistor MSK is controlled by a timing control circuit 33 provided in the power transmission side control circuit 22 . The operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com