Power generation machine for switched reluctance motor

A technology of switched reluctance motors and generators, applied to electrical components, electromechanical devices, electric components, etc., to achieve the effects of reducing switching power consumption, continuous current, and improving power generation performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

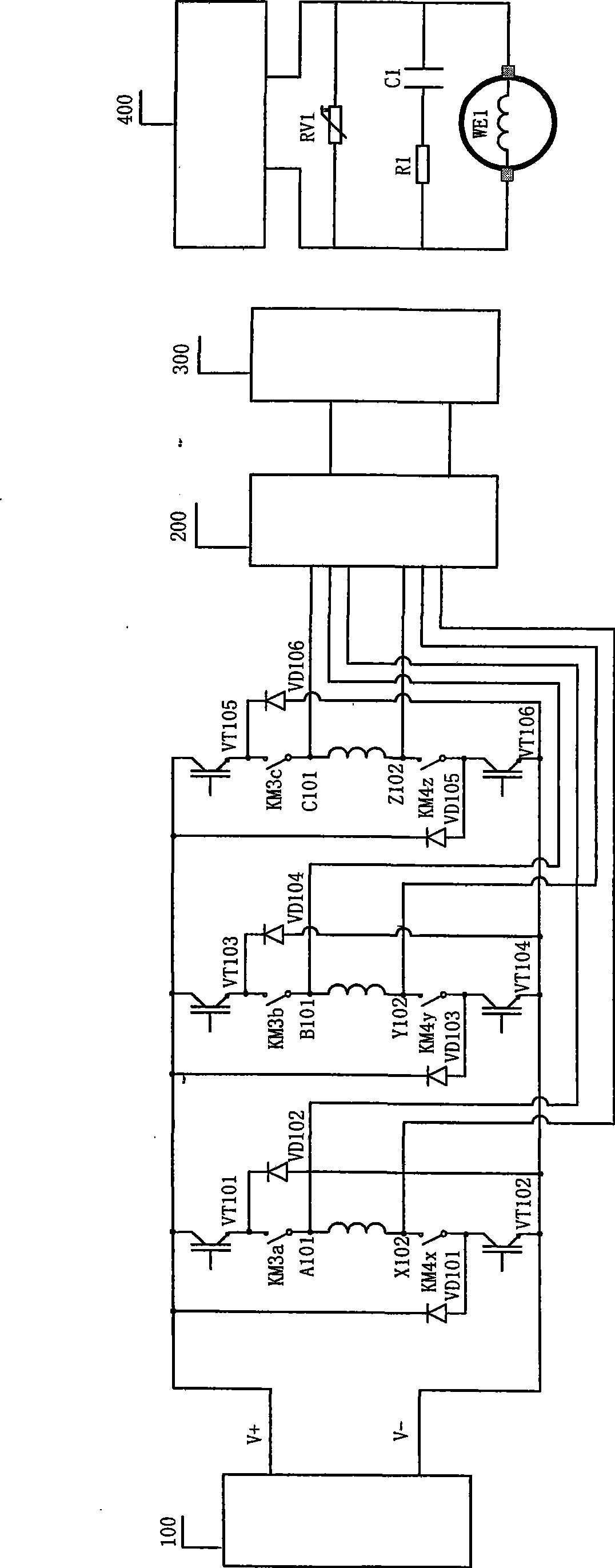

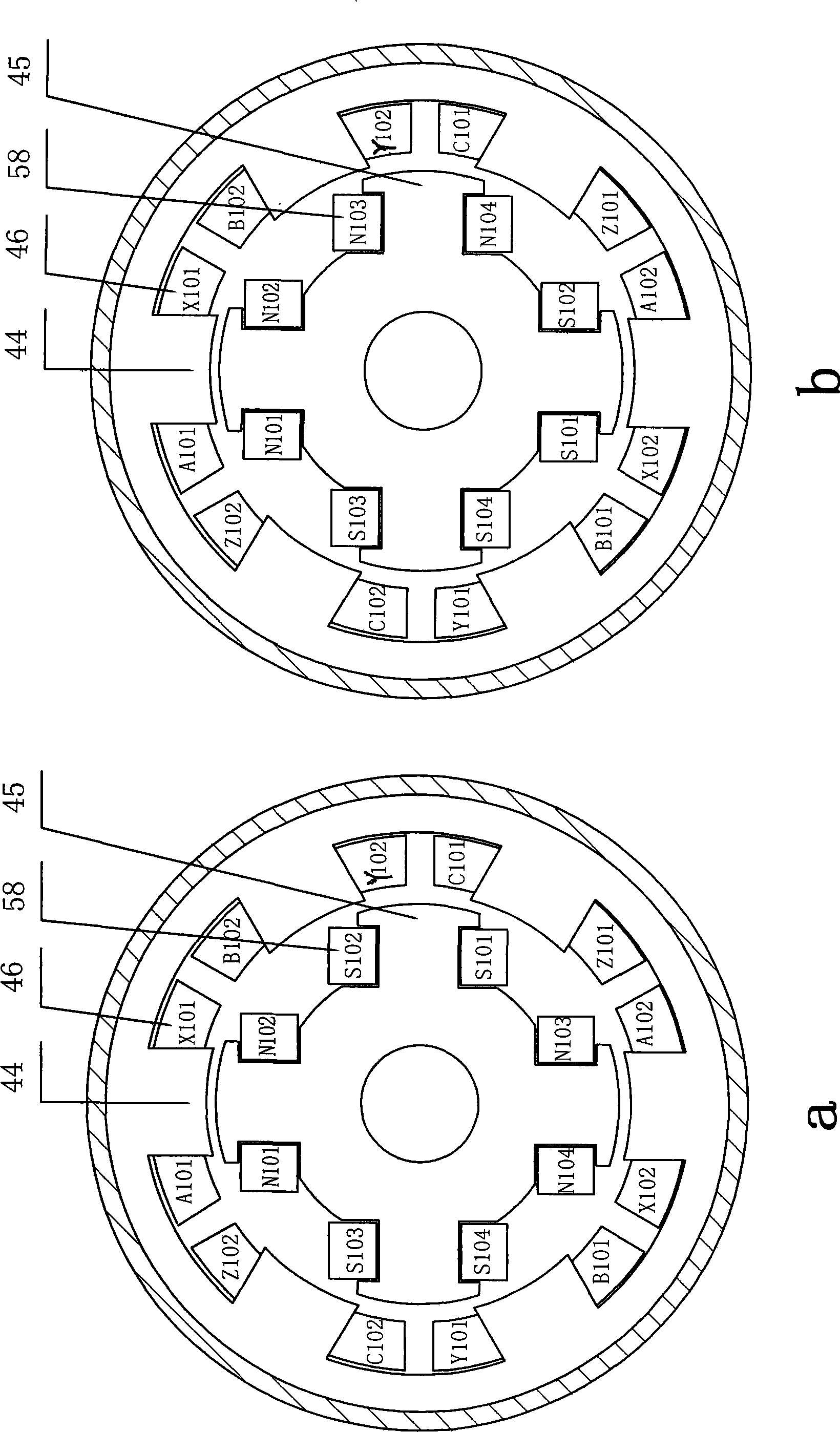

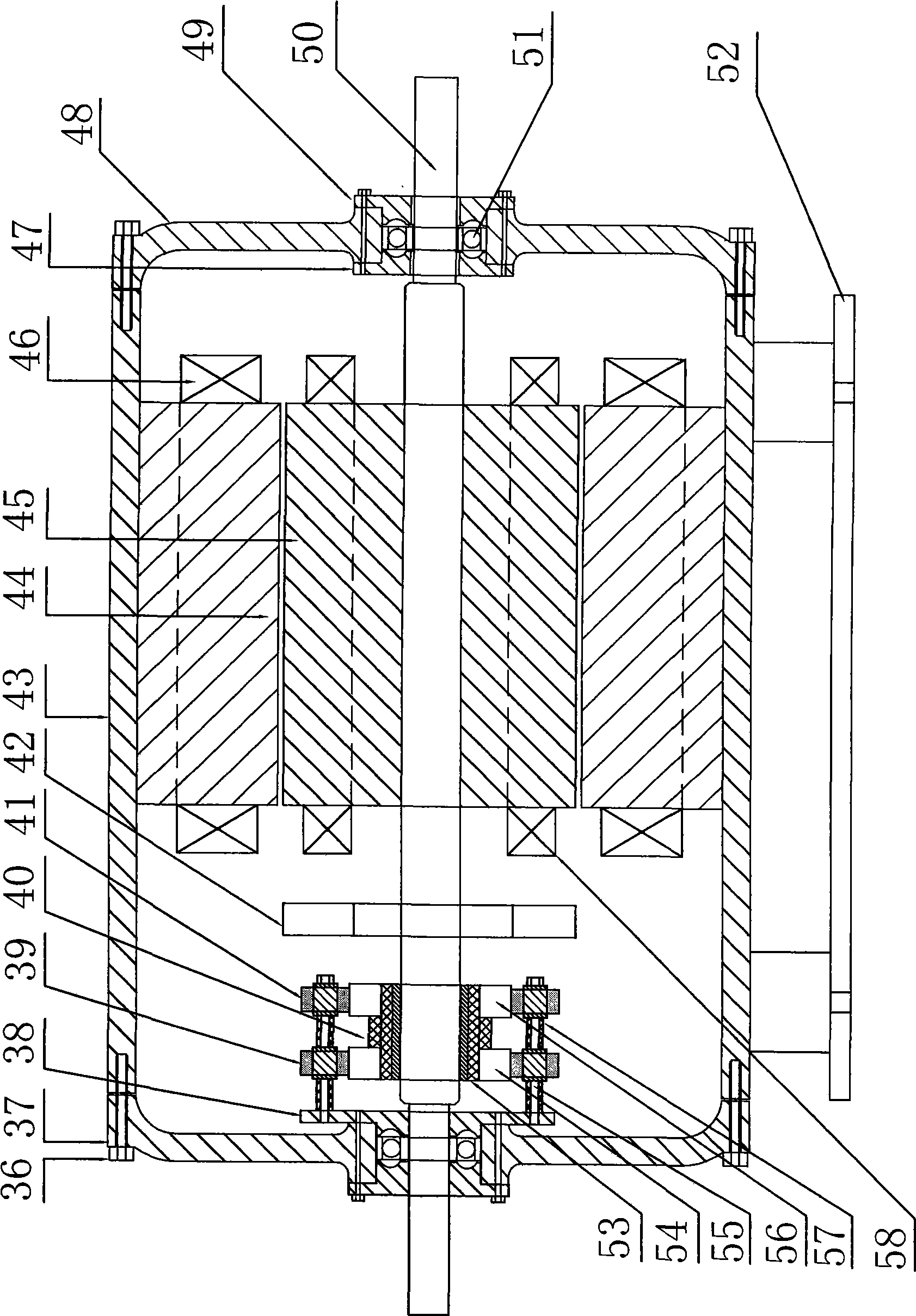

[0059] Embodiment 1 A switched reluctance motor generator (see figure 2 , 3 ), including a stator 44, a rotor 45, a rotor excitation device and an electronic sensor all laminated by silicon steel sheets into a salient pole structure, there is a concentrated armature winding 46 on the teeth of the stator 44, and the armature windings on the two teeth of the same phase of the winding 46 A phase is formed in series or in parallel, and a winding 58 is provided on the rotor 45 . The electronic sensor is mounted on the motor shaft 50 inside the motor.

[0060] The manufacturing installation of stator 44, rotor 45 can adopt figure 2 In 2a or 2b two ways. Among them, A101, B101, and C101 are the first ends of the stator S pole winding 46; A102, B102, and C102 are the first ends of the stator N pole winding 46; X101, Y101, and Z101 are the tail ends of the stator S pole winding 46; X102, Y102, and Z102 are the stator N N101 and N103 are the first ends of rotor N-pole winding 58; ...

Embodiment 2

[0069] Embodiment 2 A switched reluctance motor generator (see Figure 7 ), including a stator 44, a rotor 45, a rotor excitation device and a mechanical drive device (the application number is 200710194659.5), all of which are laminated by silicon steel sheets into a salient pole structure. There are concentrated armature windings 46 on the teeth of the stator 44, and the windings with the same phase The armature windings on the two teeth are connected in series or in parallel to form a phase, and the rotor 45 is provided with a winding 58 . The mechanical drive is mounted on the motor shaft 50 outside the motor.

[0070] The manufacture and installation of stator 44 and rotor 45 are the same as in embodiment 1.

[0071] The rotor excitation device is the same as that in Embodiment 1.

[0072] Mechanical drive device (for details, please refer to the "Mechanical Drive Device of Switched Reluctance Motor" manual, but the label number this time is different from the last one,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com