Switched reluctance motor with double stators and double rotors

A switched reluctance motor, stator and rotor technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve unsolved problems such as low vibration and low noise, and achieve amplitude reduction, electronic control reduction, Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

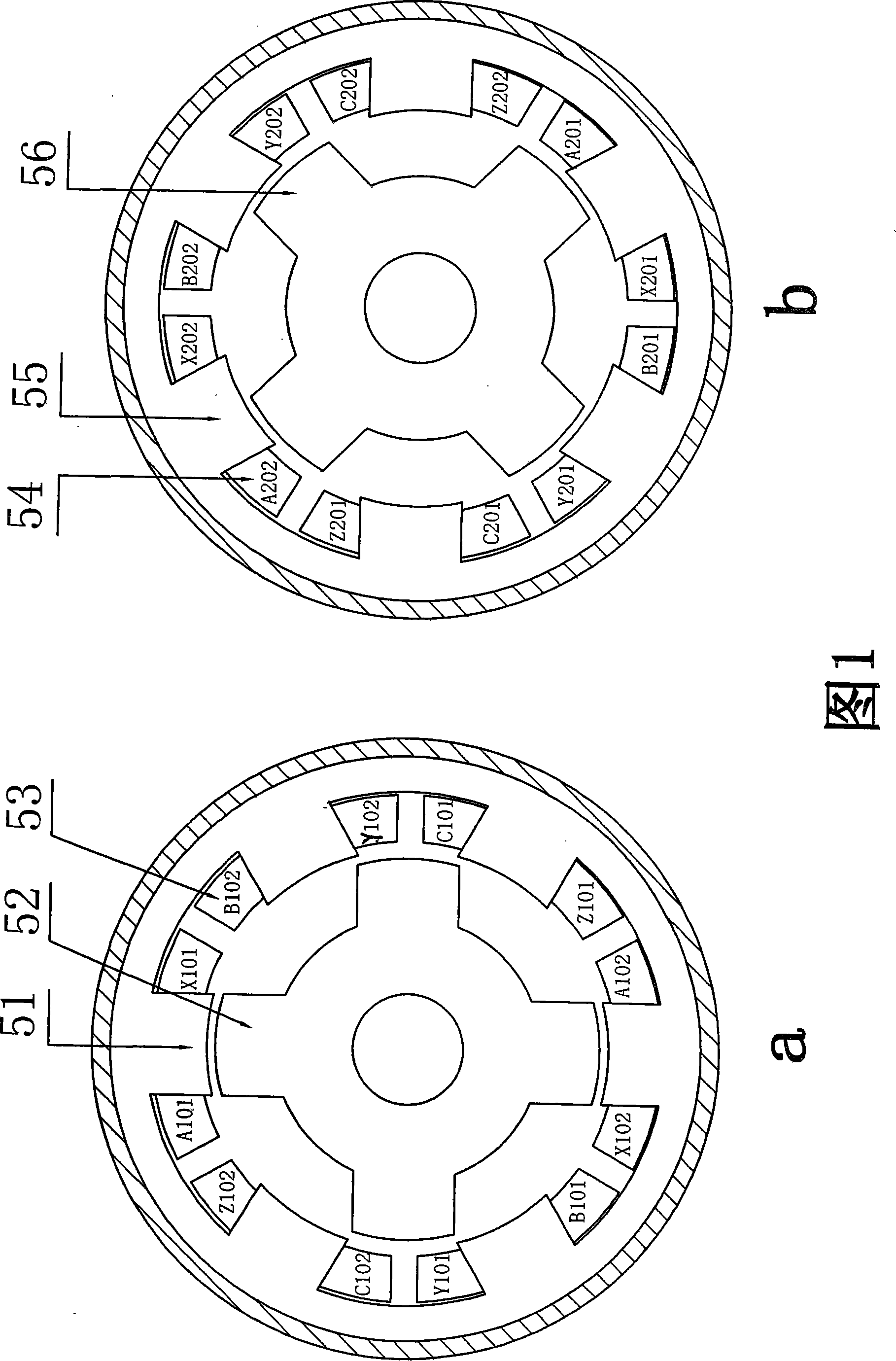

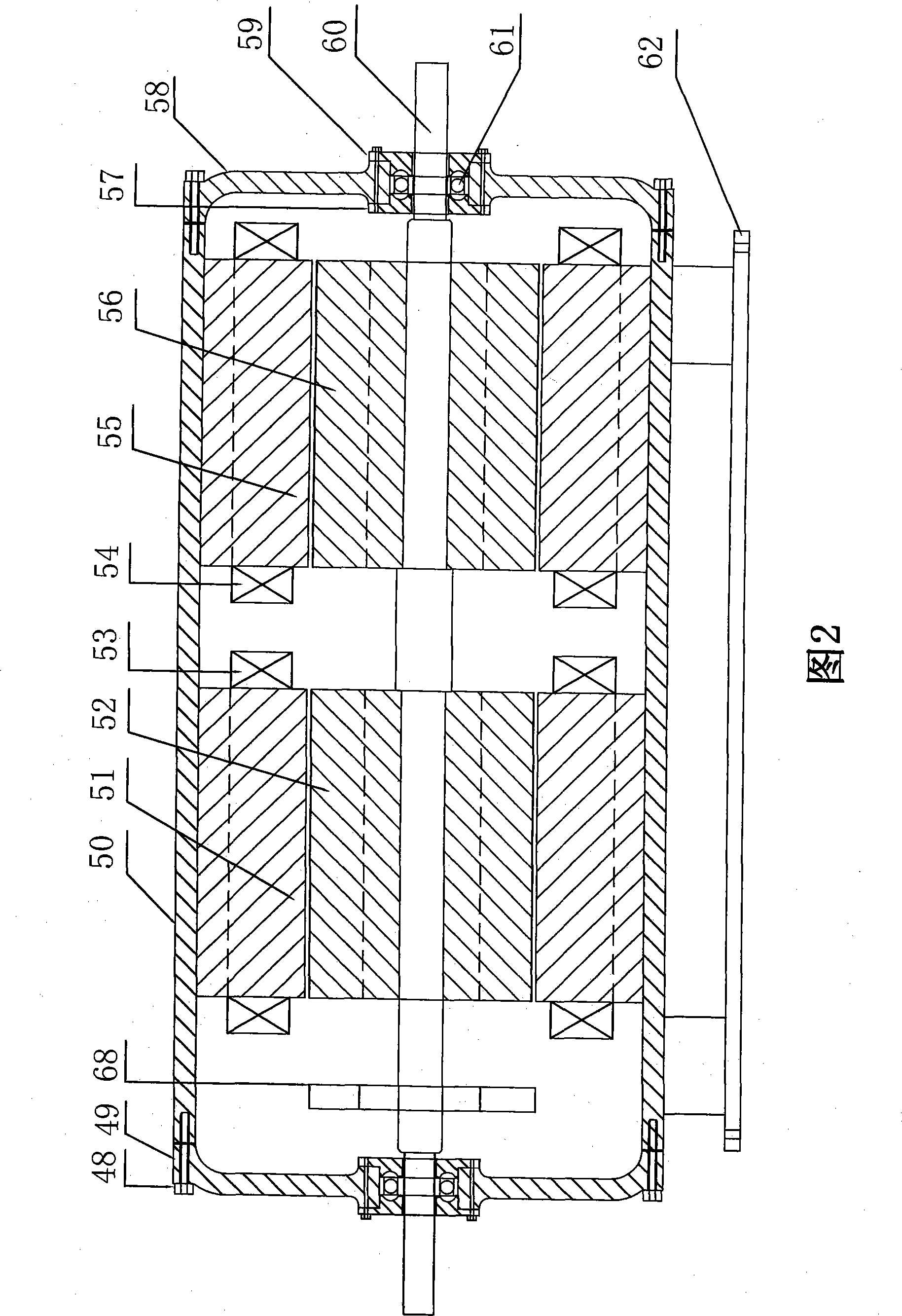

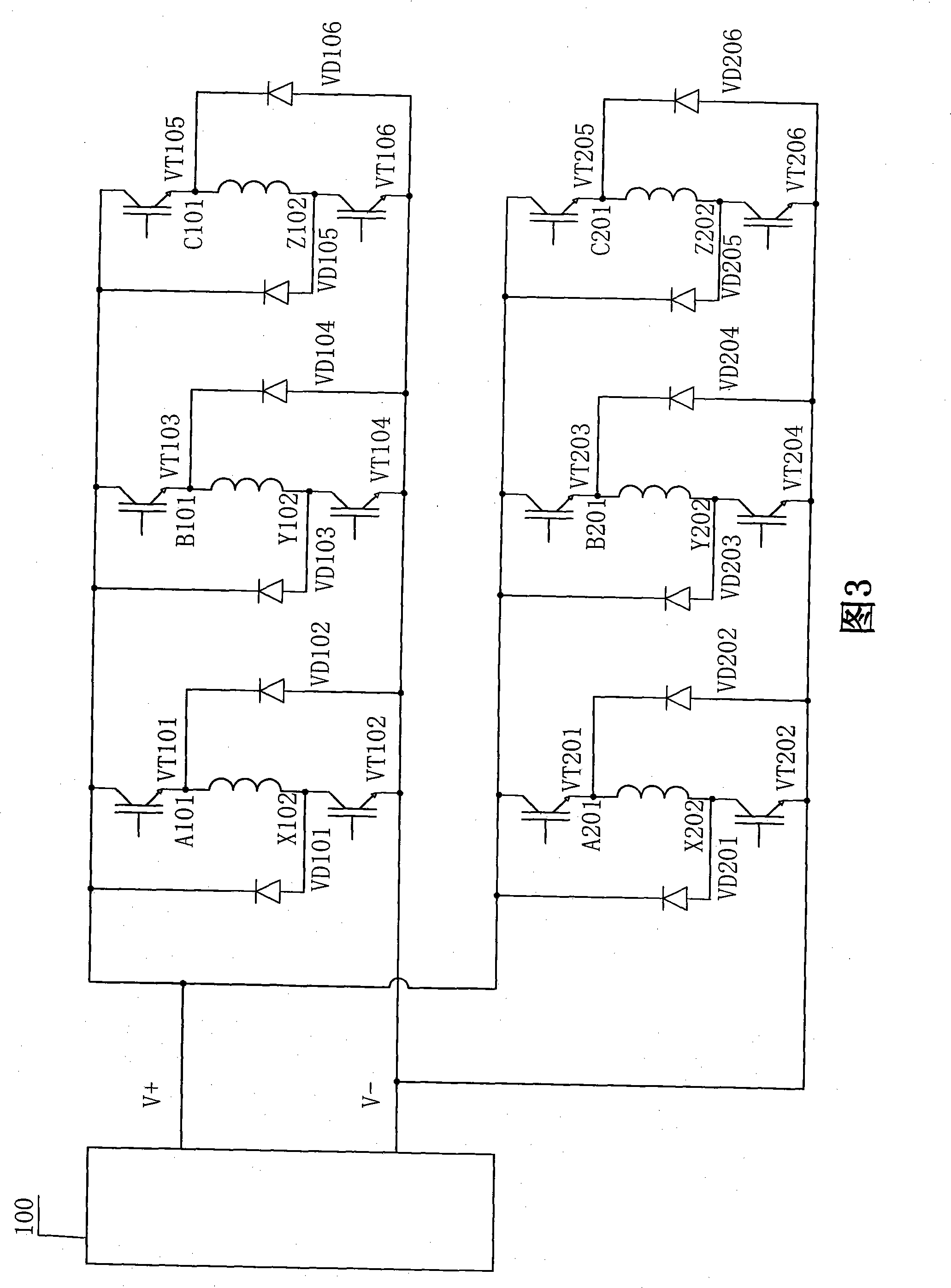

[0149] Example 1 A dual stator and rotor switched reluctance motor (see figure 1 ), including the first section of the stator 51, the second section of the stator 55, the first section of the rotor 52, and the second section of the rotor 56 which are all laminated by silicon steel sheets into a salient pole structure. Two sets of concentrated armature windings are respectively installed on the stator teeth 53 and 54, the armature windings on the two teeth of the same phase of each set of windings are connected in series or in parallel to form a phase. The two stators and rotor cores have the same length, diameter, and frame number, and the two stators are staggered by 30 degrees. Electrical angle; the two rotors are staggered by 45 degrees in electrical angle.

[0150] The manufacturing and installation of the first stage stator 51 and rotor 52 are as follows: figure 1 Shown in a: A-phase stator poles are installed at 90 degrees perpendicular to each other, a pair of magnetic pole...

Embodiment 2

[0188] Example 2 A dual stator and rotor switched reluctance motor generator (see Picture 12 , Figure 15 ), including the stator, rotor, rotor excitation device and driving device which are all laminated by silicon steel sheets into a salient pole structure. The stator and rotor cores are composed of two sections, and the two sections have the same length. The stator teeth are equipped with two sets of concentrated Armature winding, each set of windings with the same phase of the two teeth on the armature winding in series or in parallel form a phase, the two stators and rotor cores have the same diameter and the same frame number, and both rotors are equipped with excitation windings, and The two sections of stator are staggered by 30 degrees in electrical angle, and the two sections of rotor are staggered by 45 degrees in electrical angle.

[0189] The first section of stator 51, rotor 52 and the second section of stator 55, rotor 56 are manufactured and installed as in the fi...

Embodiment 3

[0202] Example 3 A dual stator and rotor switched reluctance motor generator (see Figure 18 , Picture 20 ), including the stator, rotor, rotor excitation device and driving device which are all laminated by silicon steel sheets into a salient pole structure. The stator and rotor cores are composed of two sections, and the two sections have the same length. The stator teeth are equipped with two sets of concentrated Armature winding, the two teeth of the same phase of each winding are connected in series or in parallel to form a phase. The two stator and rotor cores have the same diameter and the same frame size. One of the two rotors is equipped with an excitation winding. , And the two stators are staggered by 30 degrees in electrical angle, and the two rotors are staggered by 45 degrees in electrical angle.

[0203] The first section of stator 51, rotor 52 and the second section of stator 55, rotor 56 are manufactured and installed as in the first embodiment. The installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com