Microshock fine cutting surgical knife handle

A scalpel handle and micro-vibration technology, applied in the direction of dissection instruments, etc., can solve the problems of skin wrinkling, the blade is difficult to cut accurately and efficiently, and it is not easy to cut accurately, so as to achieve the effect of efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

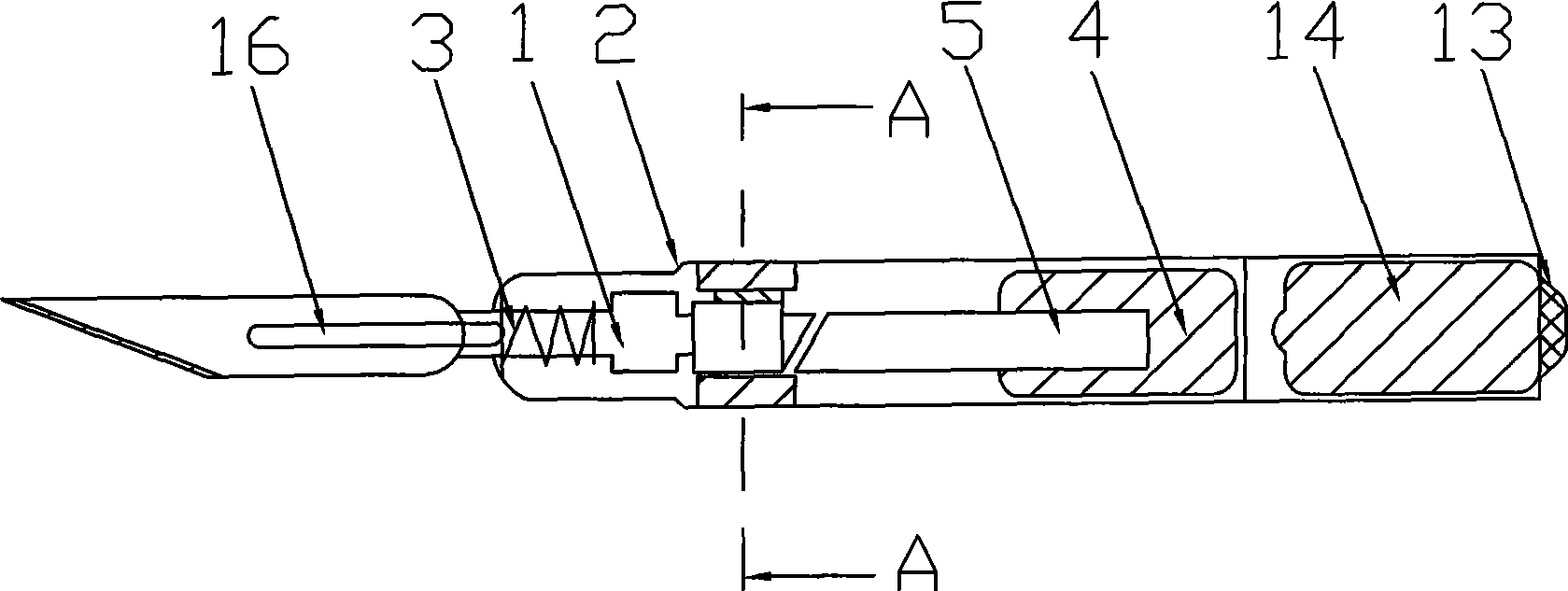

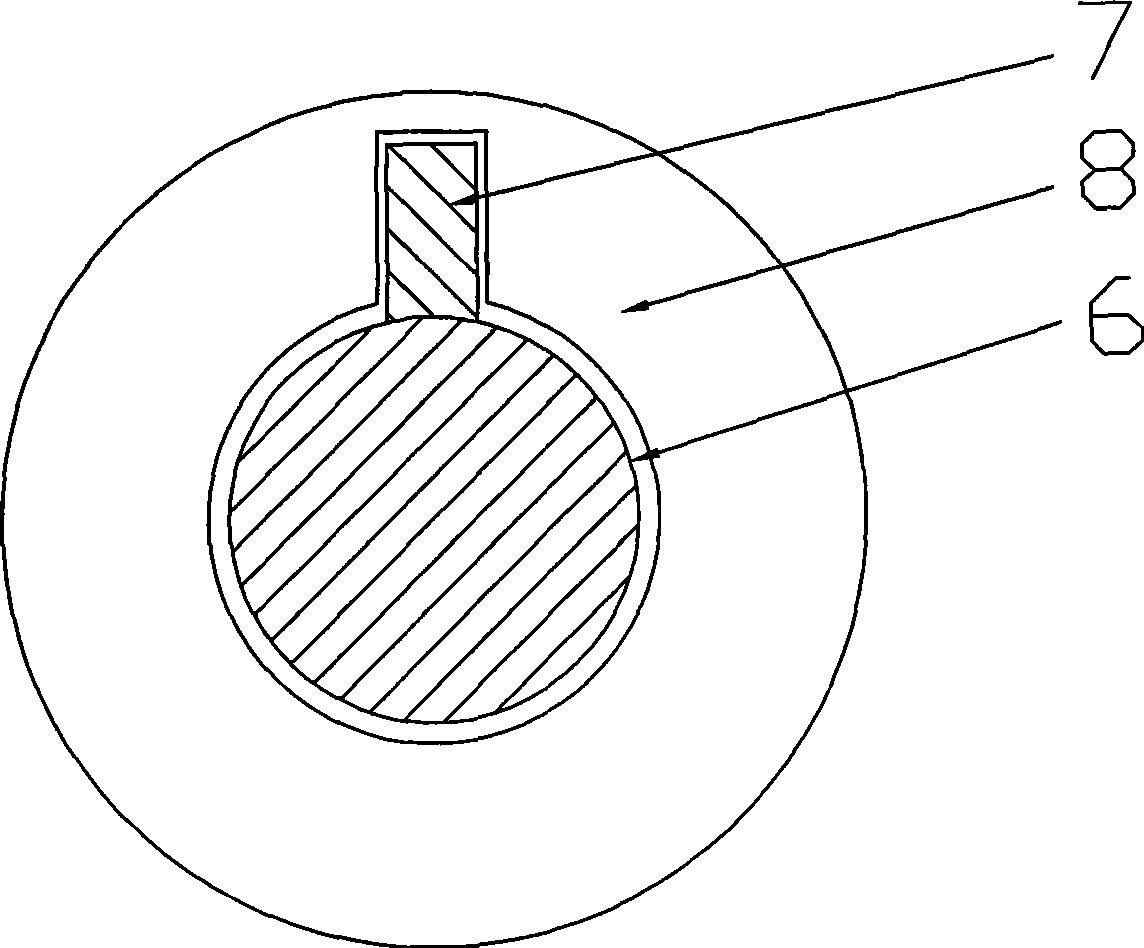

[0029] Such as figure 1 , figure 2 with Picture 9 As shown, the present invention includes a blade connector 1, a housing 2, a spring 3, a motor 4, a motor shaft 5, a battery 14, a switch and an external power source 13, and a transmission device between the blade connector 1 and the motor shaft 5. The motor 4 and the power supply device are located at the end of the inner cavity of the housing 2, the spring 3 penetrates and is connected to the blade connector 1, and the other end is connected to the front end of the inner cavity of the housing 2; The blade connector 1 and the blade are connected by a slot joint 16. The cross-section of the slot coupling member 16 is an I-shaped slot, and the card slot cooperates with the card hole on the blade so that the blade is fixedly connected to the slot coupling member 16. The transmission device is a movement direction conversion member, the movement direction conversion member includes a transmission shaft 6, a flat key 7 and a fixing ...

Embodiment 2

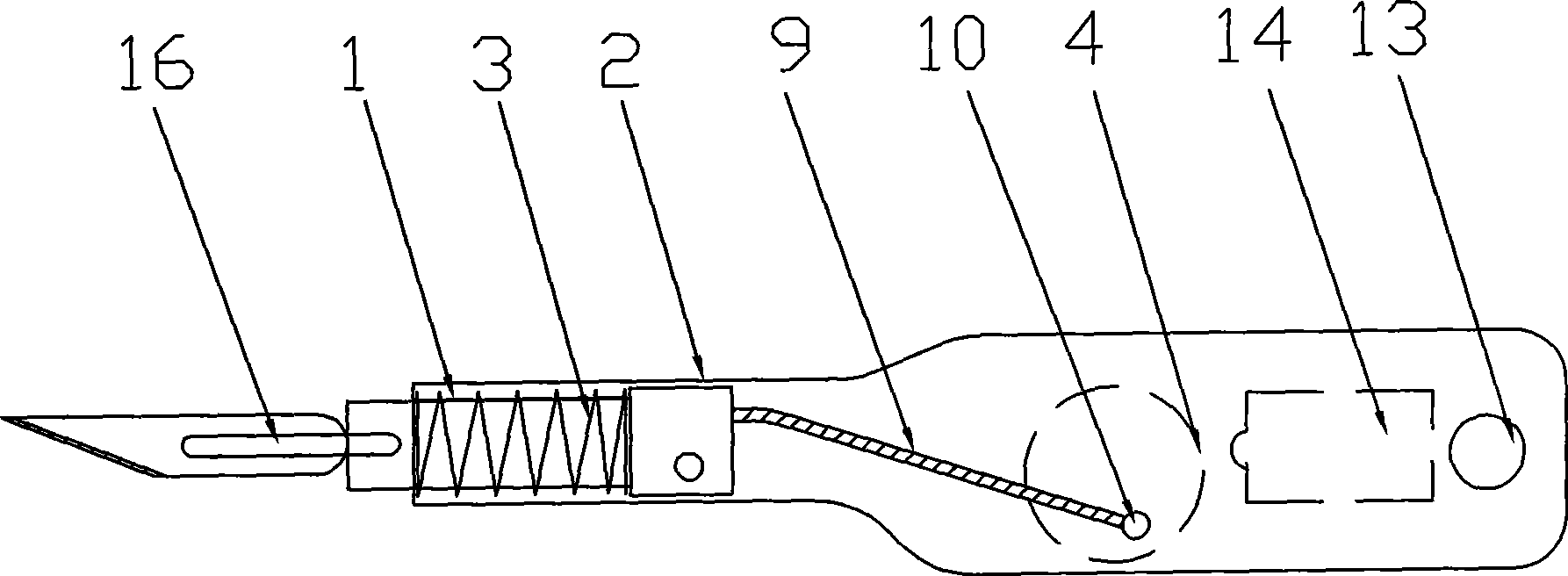

[0031] Such as image 3 with Picture 9 As shown, the structure of the transmission device in this embodiment is different from that in the first embodiment. The transmission device may also be a bending link 9; one side of the motor shaft 5 is welded with a secondary shaft 10 in parallel; one end of the bending link 9 is rotatably connected to the blade connector 1, and the other end is rotated Connected to the secondary shaft 10; when the secondary shaft 10 rotates under the action of the motor 4, it drives the bending link 9 to swing, and the bending link 9 then drives the blade connector 1 to make a longitudinal reciprocating motion.

Embodiment 3

[0033] Such as Figure 4 , Figure 5 with Picture 9 As shown, the transmission device in this embodiment is a connecting rod 11, and other structures remain unchanged; a side shaft 10 is welded parallel to the motor shaft 5, and the A end of the connecting rod 11 is connected to the blade connector 1 In a fixed connection, the B end has a circular hole with a diameter larger than that of the secondary shaft 10, and the secondary shaft 10 is sleeved in the circular hole. When the secondary shaft 10 swings, under the reaction force of the spring 3, the connecting rod 11 is reciprocated in the A and B directions; because the connecting rod 11 and the blade connector 1 are fixedly connected, the connecting rod 11 The reciprocating motion can be directly transmitted to the blade connector 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com