Ointment pumping filler material for mine roadway support and preparation

A filling material and entry retaining technology, which is applied in the field of paste pumping filling materials and preparations for mine entry support, can solve problems such as waste of energy costs, environmental pollution, unfavorable market promotion, etc., to achieve mine safety production guarantee, reduce Production cost, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

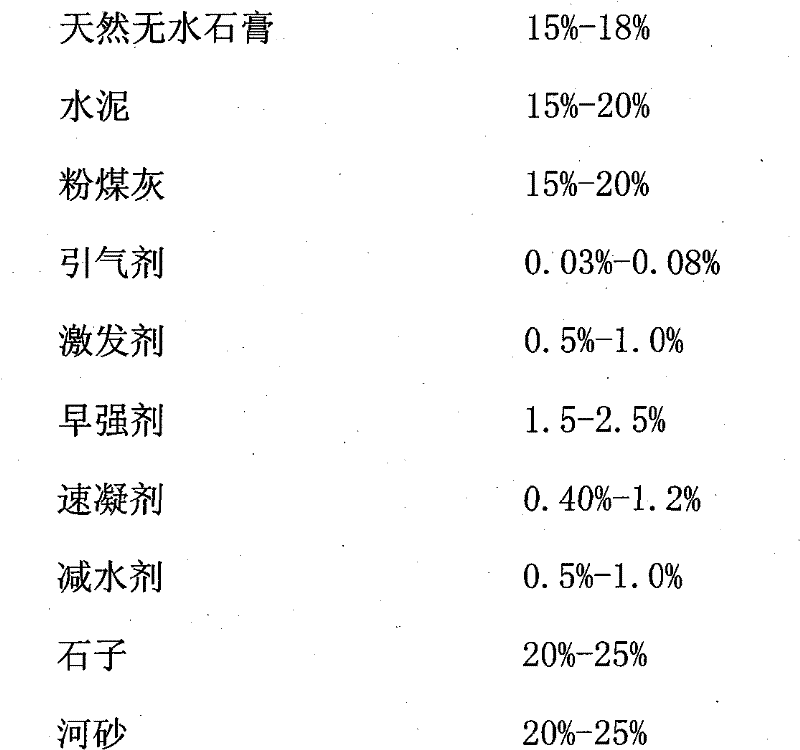

[0027] Natural anhydrite 15%-18%

[0028] Cement 15%-20%

[0029] Fly ash or blast furnace slag 18%-25%

[0030] Air-entraining agent 0.03%-0.08%

[0031] Stimulator 0.5%-1.0%

[0032] Early strength agent 1.5-2.5%

[0033] Accelerator 0.6%-0.8%

[0034] Water reducing agent 0.5%-0.8%

[0035] Pebbles 20%-25%

[0036] River sand 20%-25%

[0037] During preparation, the natural anhydrous gypsum is first ground by an industrial ball mill, the fineness is controlled at 200 mesh sieve, the balance is less than 1%, and the specific surface area is 4000-5000cm 2 / g; After fully mixing the air-entraining agent, activator, accelerator, early strength agent, and water reducer in a given proportion, mix it with river sand, stones, anhydrite powder, cement and fly ash in a given proportion Mix evenly in the mixer to form a paste pumping filling material for mine roadway retaining support, and then pack it into a product. The paste pumping filling material obtained in this embodi...

Embodiment 2

[0039] Natural anhydrite 2%-3%

[0040] Cement 15%-25%

[0041] Fly ash or slag 18%-25%

[0042] Air-entraining agent 0.01%-0.04%

[0043] Stimulator 0.5%-1.0%

[0044] Early strength agent 0.5-1.5%

[0045] Accelerator 0.8%-1.2%

[0046] Water reducing agent 0.5%-0.8%

[0047] Pebbles 20%-25%

[0048] River sand 20%-25%

[0049] During preparation, the natural anhydrous gypsum is first ground by an industrial ball mill, the fineness is controlled at 200 mesh sieve, the balance is less than 1%, and the specific surface area is 4000-5000cm 2 / g; After fully mixing the air-entraining agent, activator, accelerator, early strength agent, and water reducer in a given proportion, mix it with river sand, stones, anhydrite powder, cement and fly ash in a given proportion Mix evenly in the mixer to form a paste pumping filling material for mine roadway retaining support, and then pack it into a product. The paste pumping filling material obtained in this embodiment has good fl...

Embodiment 3

[0051] Natural anhydrite 10%-15%

[0052] Cement 15%-20%

[0053] Fly ash slag 18%-25%

[0054] Air-entraining agent 0.03%-0.08%

[0055] Stimulator 0.5%-1.0%

[0056] Early strength agent 1.0-1.5%

[0057] Accelerator 0.3%-0.6%

[0058] Water reducing agent 0.6%-1.0%

[0059] Pebbles 20%-25%

[0060] River sand 20%-25%

[0061] During preparation, the natural anhydrous gypsum is first ground by an industrial ball mill, the fineness is controlled at 200 mesh sieve, the balance is less than 1%, and the specific surface area is 4000-5000cm 2 / g; After fully mixing air-entraining agent, activator, accelerator, early strength agent, and water reducer in a given proportion, mix it with river sand, stones, anhydrite powder, cement and fly ash in a given proportion Mix evenly in the mixer to form a paste pumping filling material for mine roadway retaining support, and then pack it into a product. The paste pumping filling material obtained in this example is a highly fluid fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com