Method and apparatus for measuring and compensating transmission error of electric cylinder

A transmission error and electric cylinder technology is applied in the field of detecting and compensating devices, measuring and compensating electric cylinder transmission errors. The effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Transmission error measurement

[0024] Transmission error is divided into two parts, pitch error and backlash error. When measuring the pitch error, we apply different loads to the electric cylinder. Since the influence of variable load is considered when measuring the pitch error, the backlash error is no longer loaded.

[0025] In order to obtain the pitch error data of the electric cylinder with variable load, we measure the pitch error in two cases, no-load and full-load, to lay the foundation for interpolation calculation. The method and steps of the two error measurements are the same. First, the electric cylinder rod is divided into several compensation intervals on average, and the control computer controls the electric cylinder to execute the zero return command. The zero position of the electric cylinder rod is the coordinate zero point; The compensation amount is set to zero value, and this position is used as the measurement reference. After the comma...

Embodiment 2

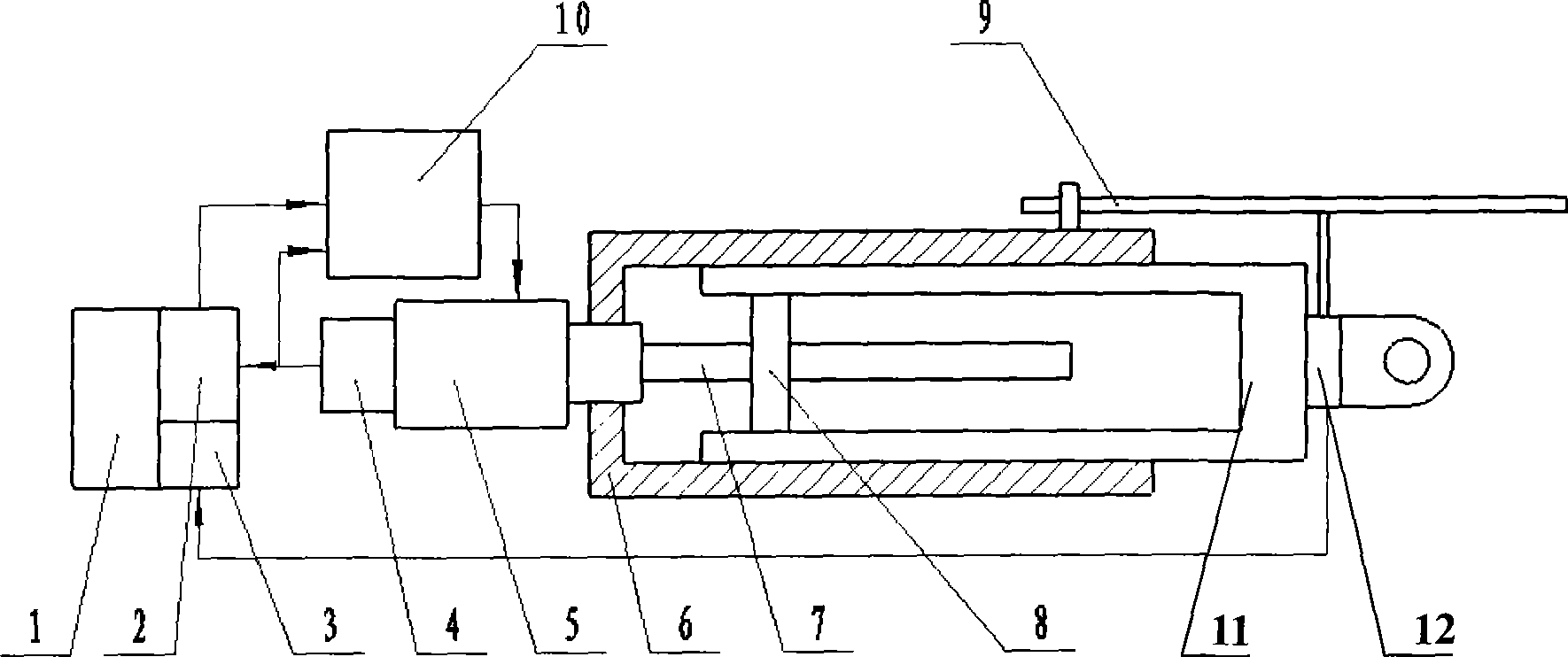

[0030] according to figure 1 , the electric cylinder control and measurement system of the present invention consists of a control computer 1, a position controller 2, a servo driver 10, an encoder 4, an AC servo motor 5, an electric cylinder housing 6, a lead screw 7, a nut 8, and an electric cylinder output rod 11 , strain gauge force sensor 12, digital display magnetic ruler 9 and A / D interface card 3 constitute. The control computer 1 is used to send the motion control command of the servo motor 5, the transmission error compensation command, and collect the force sensor signal; the position controller 2 is connected to the bus of the computer 11, and the position controller 2 drives the servo motor to rotate through the servo driver 10, and the feedback The encoder 4 is installed on the shaft of the servo motor, the servo motor 5 rotates through the coupling with the lead screw 7 and the nut 8, and the nut 8 moves linearly with the electric cylinder output rod 11; the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com