Strain gauge and its production method

A technology of strain gauges and polymers, applied in the field of strain gauges, can solve problems such as inability to measure large displacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of certain exemplary embodiments of the invention are exemplary in nature only and are not intended to limit the invention and its application or uses.

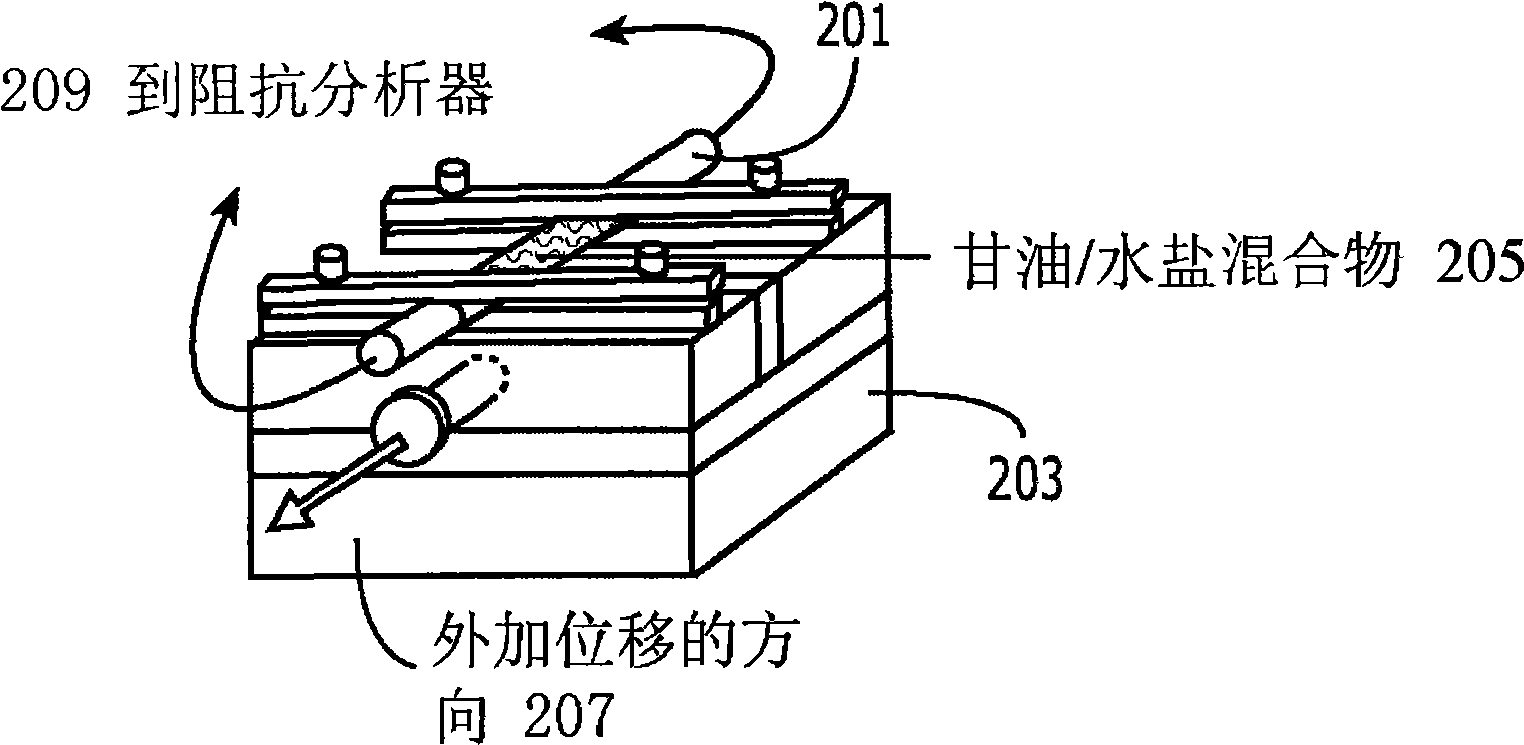

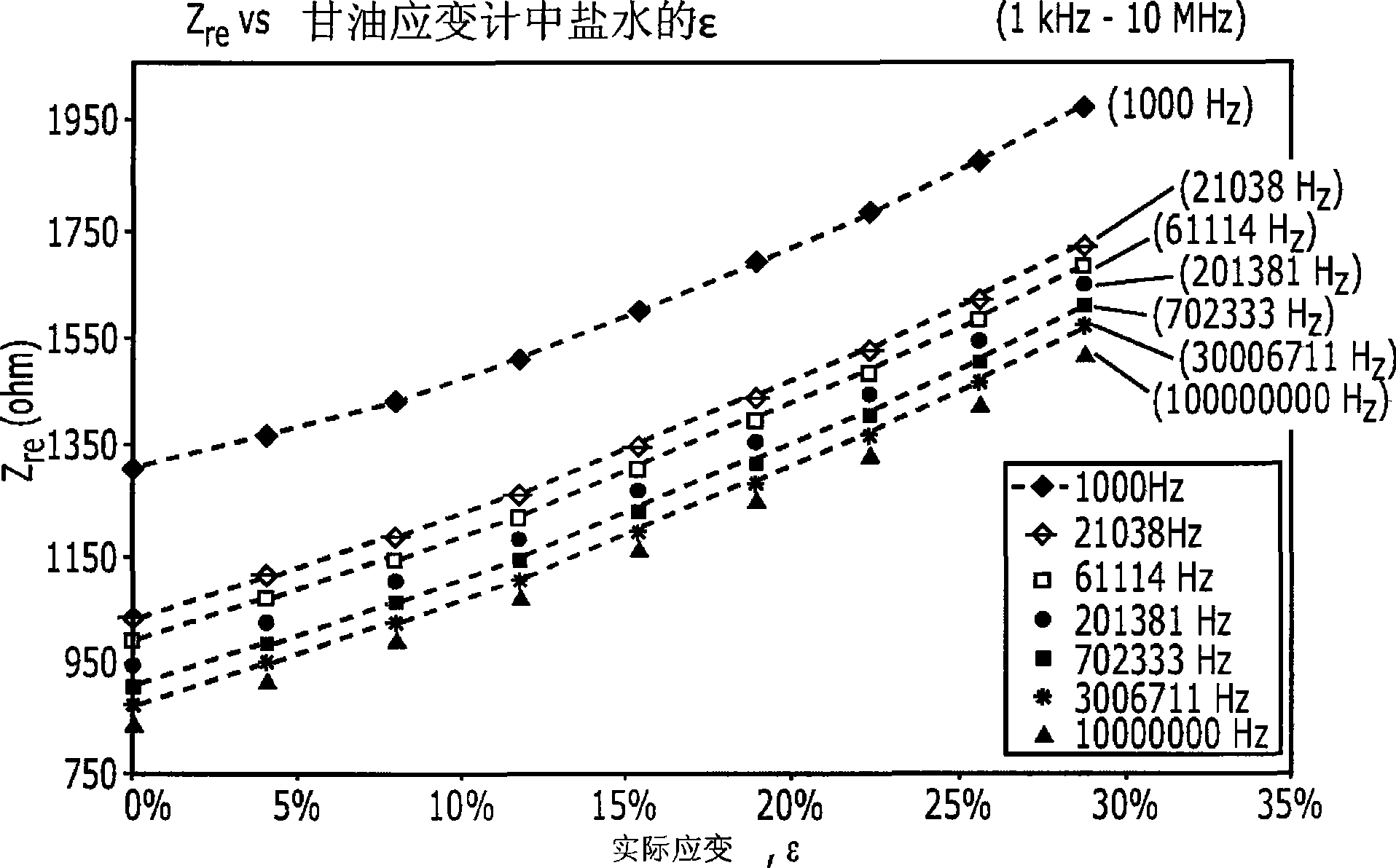

[0026] Please refer to the following Figure 1 to Figure 4 .

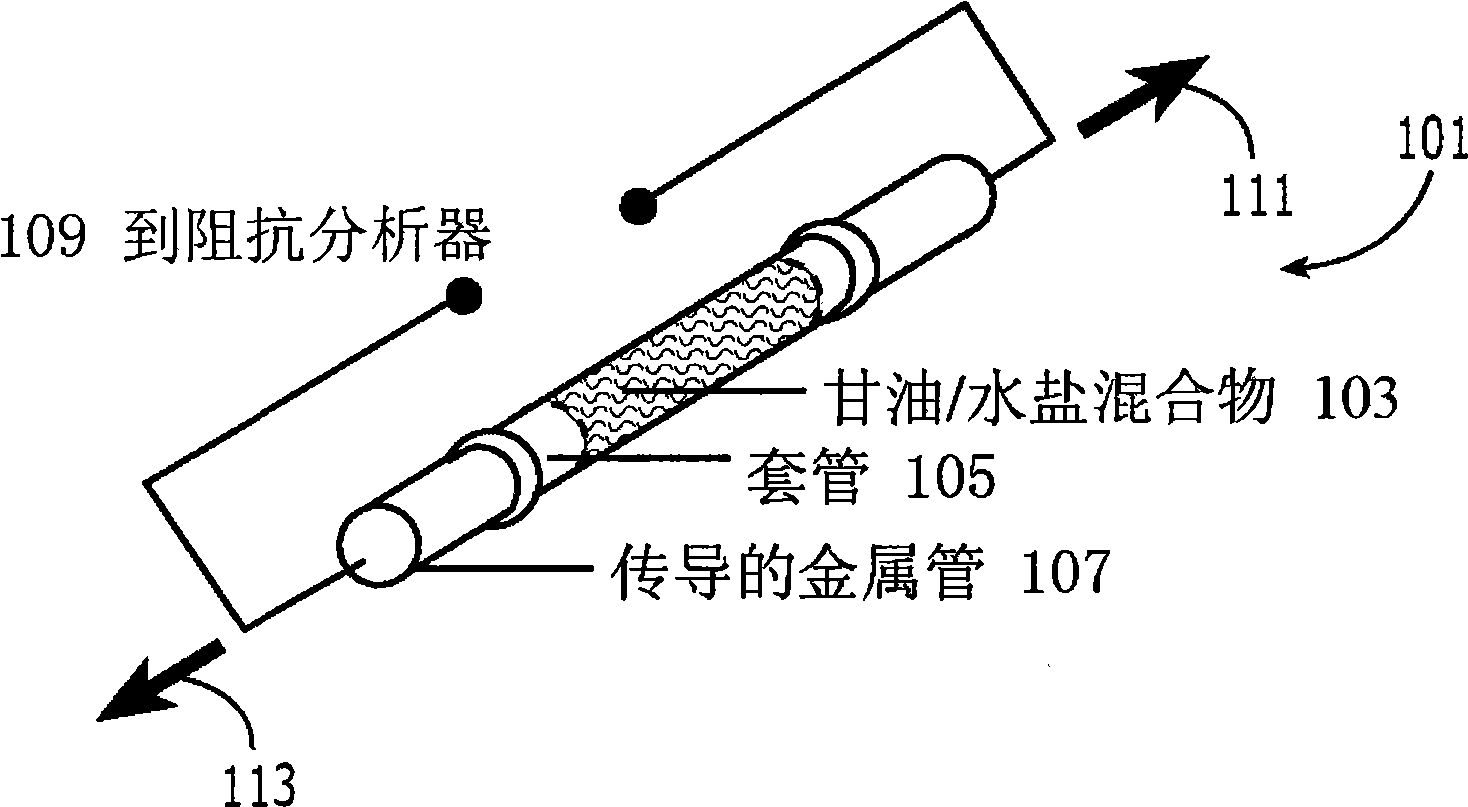

[0027] figure 1 is an embodiment of a strain gauge 101 of the present invention comprising a glycerin / water salt mixture 103 as the internal fluid of a polymeric sleeve 105 to which metal tubes 107 are connected at both ends. A lead block 107 is attached to the end of a metal tube 107 for feedback to an impedance analyzer that changes the current measurement.

[0028] The strain gauge length (the length between the two electrodes) of the bushing 105 used in the strain gauge 105 ranges from 15mm to 30mm. The sleeve 105 may be circular or other suitable shape with a radius of about 1 mm to 5 mm. The sleeve 105 may be made of a polymer, such as an elastic or rubber-like polymer. Both ends of the sleeve 105 are sealed to accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com