Electric razor

An electric and motor technology, applied in metal processing, etc., can solve the problem of heavy head weight, achieve balanced weight distribution, reduce weight, and simplify setup and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

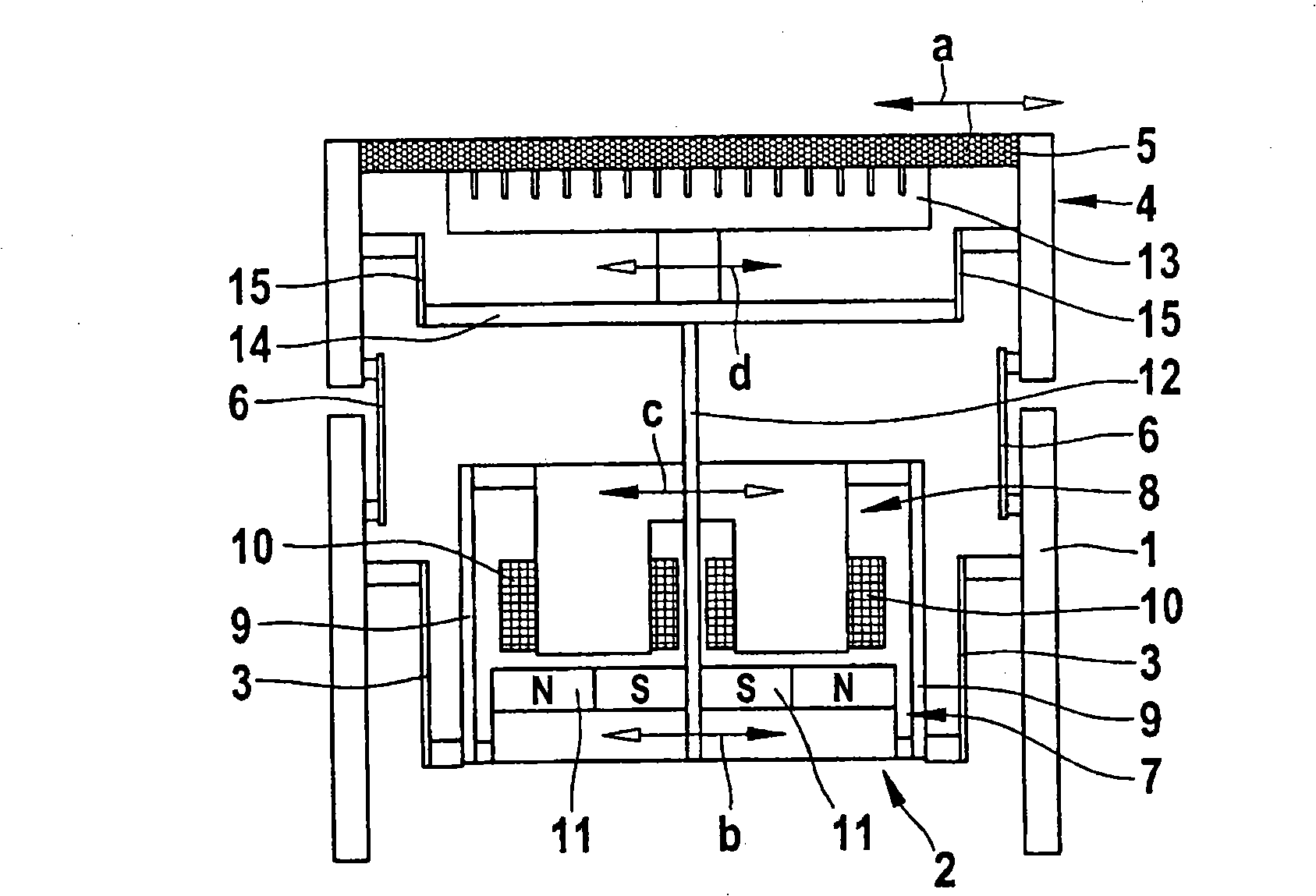

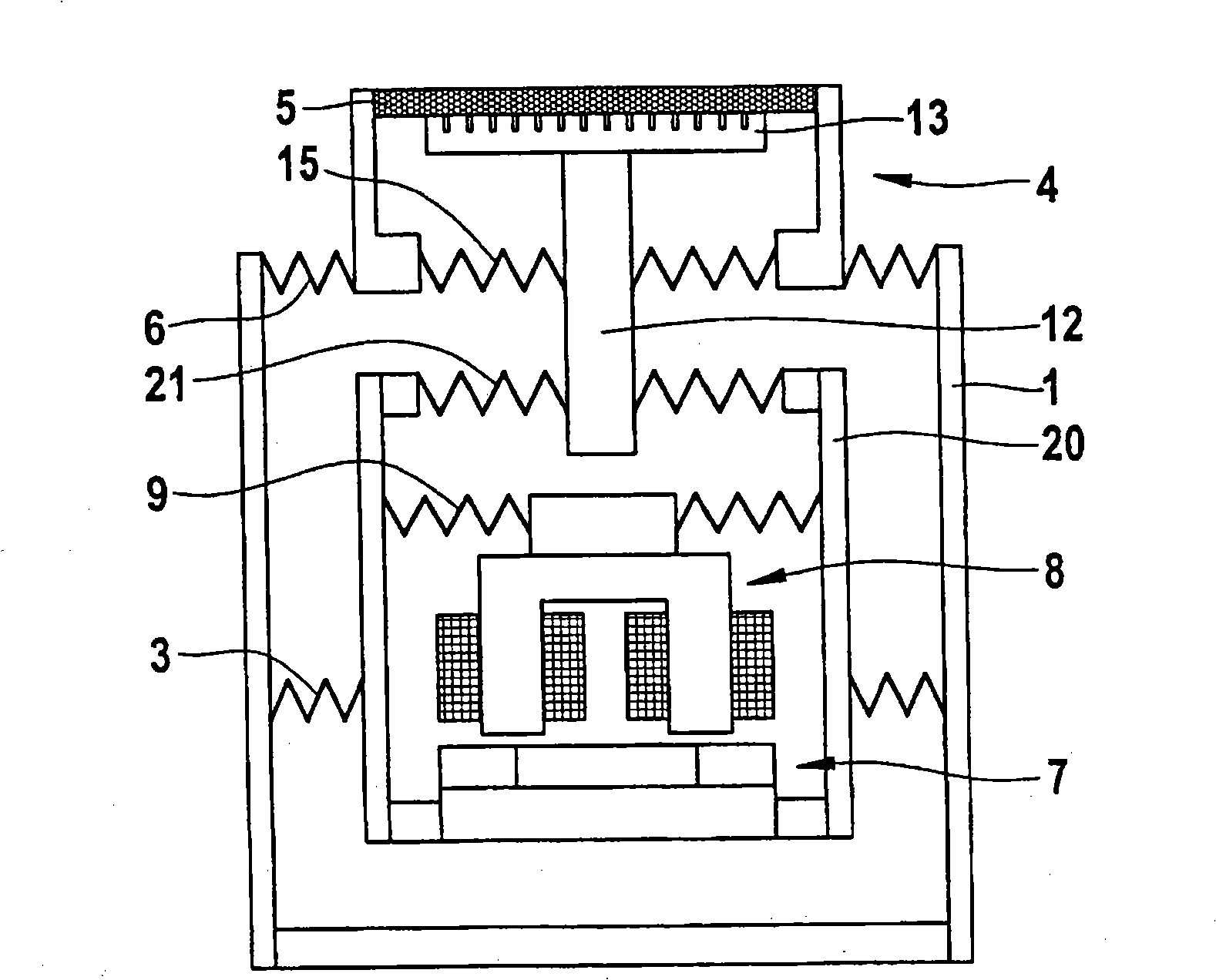

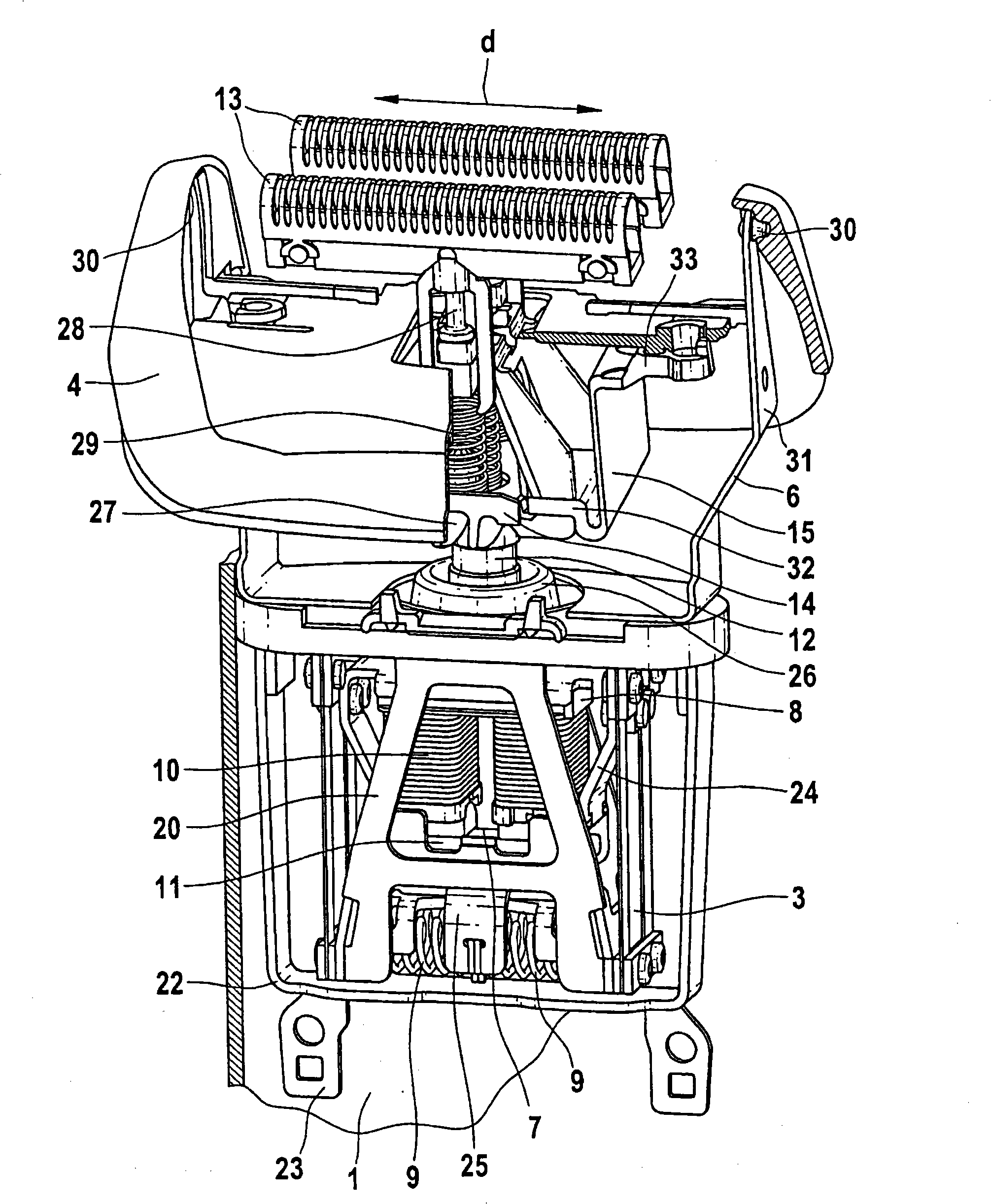

[0017] exist figure 1 The shaving apparatus schematically shown in has a housing 1 held in the hand of the user, which houses the electric motor 2 as well as the energy supply in the form of accumulators and / or power supply parts, not shown in its view, and the complete motor control , switch, etc. The electric motor 2 is elastically supported in the housing 1 by means of a motor suspension 3 designed as a plurality of leaf springs in order to prevent the transmission of motor vibrations to the housing 1 .

[0018] The trimming head 4 carries at least one trimming sheet 5 , which is a first trimming element, and the trimming head 4 is connected to the housing 1 in a vibrating manner by means of two trimming head carriers 6 . The leaf-spring-shaped trimming head carrier 6 permits lateral vibrations of the trimming head 4 and thus of the trimming blade 5 in the plane of the drawing, as indicated by the double arrow a.

[0019] The electric motor 2 is formed from a first rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com